How Collaborative Robots (Cobots) are Enhancing Human-Robot Collaboration in Warehouses?

25-Feb-2025

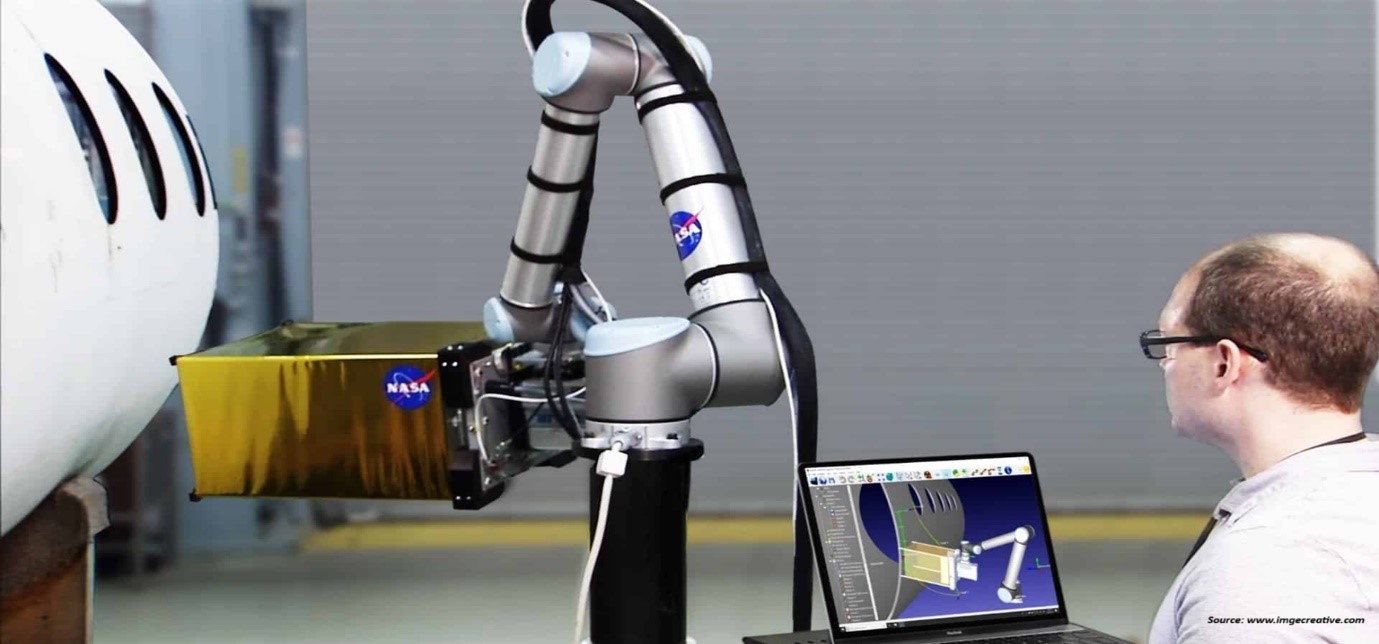

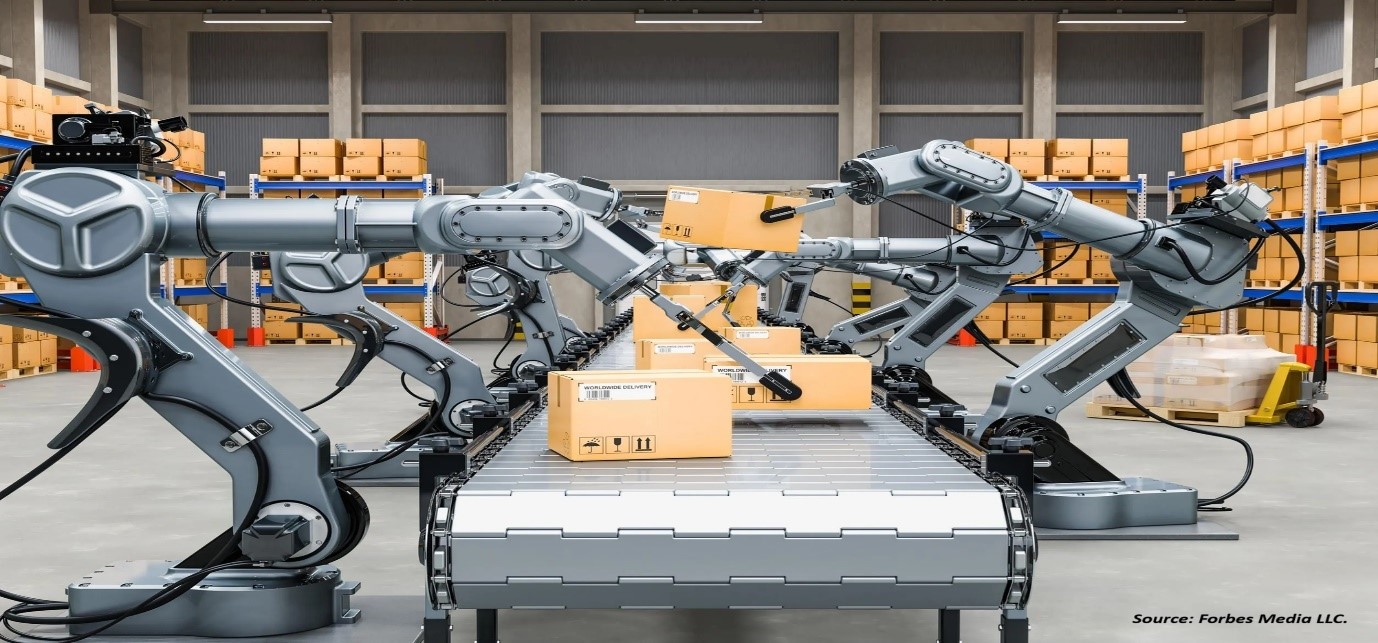

Collaborative robots are used in warehouse operations to revolutionize supply chain efficiency by optimizing workflows and improving human-robot collaboration. Cobots work alongside the human workforce and ensure a smooth, efficient environment in the warehouse. These smart robotic systems avail the benefits of artificial intelligence, machine learning, and advanced sensors to improve material handling, inventory management, and order fulfilment. Due to increasing e-commerce and fast home deliveries, companies are including cobots in their warehouse operations to smoothen their operations, reduce operational costs, and increase workplace safety.

This blog covers collaborative robotics' transforming warehouse operations through how they interact to improve efficiency levels in a supply chain. Their impact involves developing workforce cooperation with logistics enhancements, among many. It expounds on pivotal issues such as cutting-edge developments taking place in front of AI-motivated automation, predictive maintenance, and safety measures in relation to each end. From covering recent incidents inside the market landscape, to newer product launching and strategic cooperation creates innovation on warehousing robots.

Unlock a FREE Sample of the Collaborative Robots Market – Try Before You Buy!

Importance of Cobots in the Warehouse Robotics Market

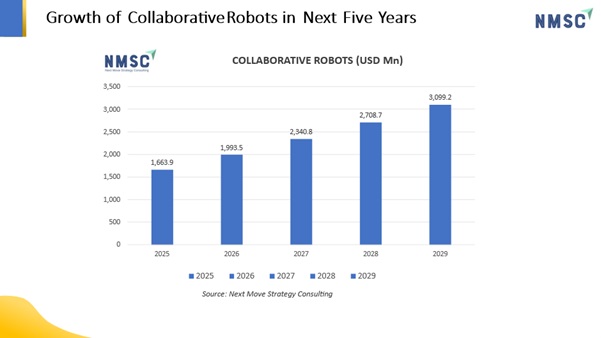

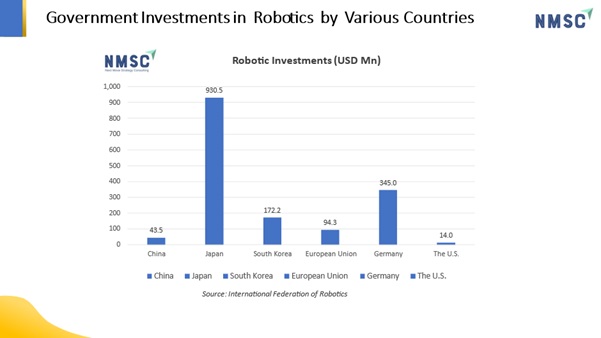

The warehouse robotics global market keeps growing with the growth of labour costs, increasing volumes of orders, and the necessity of working efficiently. Cobots started to find their places in the area of solving these challenges, partly by helping human workers with physically demanding and repetitive tasks. With demand rising for the automation solutions, governments and logistics companies around the world started investing in cobot-powered systems with the aim of improving supply chain resilience and optimizing warehouse productivity.

A report by the Internation Federation of Robotics states that Ohio-based metal fabricator Raymath saw a phenomenal 200% increase in welding production and a 600% increase in machine tending after adopting cobots. This success underlines the potential of the cobots for significant enhancement in operational efficiency within different industries and further cements their rising importance in both warehouse and manufacturing environments.

Enhanced Order Fulfilment and Inventory Management

Improved order fulfilment and inventory management are required to achieve high supply chain efficiency and customer satisfaction. Businesses, supported by technologies such as AI and automated systems, will be at ease in operations, reduce errors, and speed up the pace of delivery. Good inventory control prevents overstocking and stockout situations, therefore minimizing costs while improving operational efficiency.

For example, in February 2025, Brightpick launched the Giraffe robot to substantially improve how firms deal with high-reaching storage racks and bulky items in the warehouse by working effectively with human operators to increase throughput while decreasing manual work. Integration of such advanced technologies optimizes warehouse operations while guaranteeing an overall improvement in supply chain performance through customer satisfaction and business growth.

The Role of AI in Warehouse Robotics

AI-driven cobots leverage machine learning, computer vision, and real-time data analytics for warehouse workflow optimization. Different conventional automation systems, these cobots can adapt to dynamic environments, learn from human interactions, and optimize the way tasks are performed. Equipped with AI capabilities, a warehouse will have the ability to seamlessly manage its inventories, take precise order fulfillment, and lowered operational costs.

AI-Powered Warehouse Safety and Risk Mitigation

As warehouse environments become increasingly automated, the safety of workers stands at the forefront. AI driven cobots are designed with advanced sensors and machine learning algorithms to detect obstacles, avoid collisions, and operate in safety with human workers. In fact, ABB YuMi, a cobot, is engineered featuring human-friendly sides, soft edges, and force-limiting technology to prevent injury. This ensures that the warehouses maintaining high standards for safety while boosting productivity.

Automated Logistics and Predictive Maintenance

Cobots perform the optimization of warehouse logistics through automated inventory replenishment, transportation of goods, and navigation of the warehouse. Artificial Intelligence-powered warehouse robotics solutions are expected to drive significant cost efficiencies and operational enhancements in the warehouse robotics market.

Also, a highly adaptable collaborative robot called Proxie powered by advanced AI was launched by Collaborative Robotics. It integrates mobility, modular manipulation systems, and refined situational awareness to automate material handling tasks in a much better way across a wide array of industries. Proxie is designed to interact with humans easily, hence improving safety and productivity in shared workspaces. Thus, such innovations are sure to transform warehouse logistics with better efficiency, safety, and productivity due to AI-enabled automation and human-robot collaboration.

AI-Integrated Warehouse Robotics Management Systems

Modern warehouse robotics management systems (WRMS) integrate AI and cobot-driven automation to enhance decision-making, optimize resource allocation, and improve real-time data visibility. In November 2024, Geek+ also upgraded its robot management system to operate more than 5,000 robots and handle 10,000 tasks per second to enable better order fulfilment during the peak holiday period. The new system boosts scalability, speed, and efficiency, with CPU and memory usage down while allowing a business to handle increased demand. It integrated with Geek+ suite of automation solutions and delivers top performance during peak throughput. These latest developments within warehouse robotics management systems let businesses scale their operations with ease and meet growing demand efficiently while yielding better productivity through seamless automation and AI-driven optimization.

Latest Developments in AI-Driven Collaborative Robotics

AI-Enhanced Autonomous Warehousing Solutions

The AI-driven autonomous warehousing solution is one of the fastest growing industries. For instance, DHL Supply Chain announced its partnership with Robust.AI to design and implemented a group of pioneering warehouse robots. The partnership announced to pilot a 'Carter' collaborative mobile robot in order to help advance the materials handling process inside a warehouse. Equipped with artificial intelligence, Carter learns in real time from real warehouse conditions and optimizes workflows for maximum productivity. These developments thus illustrate the increased adoption of AI-integrated cobot solutions in the warehouse robotics market.

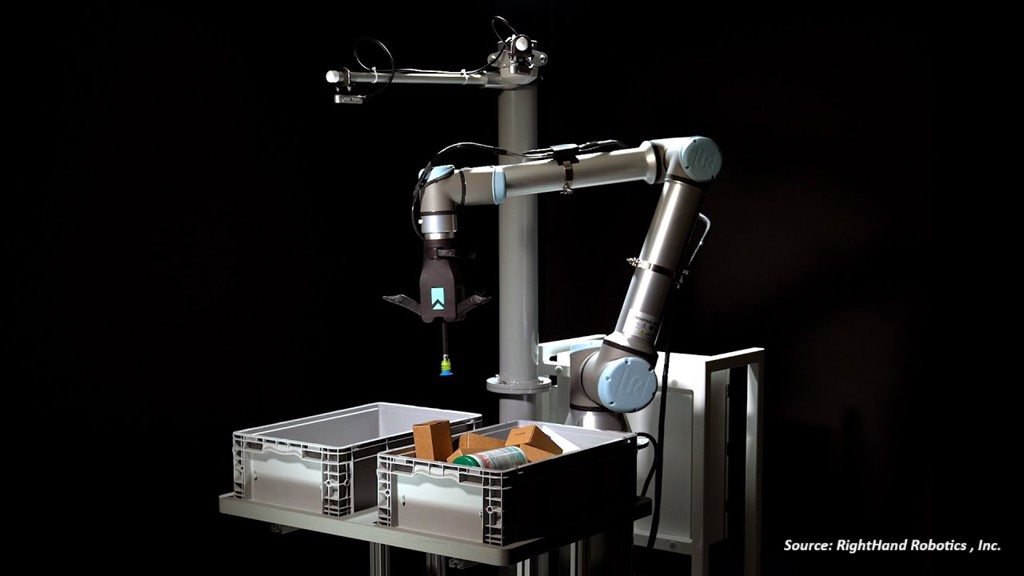

AI-Driven Object Recognition and Grasping Technology

Using AI-operated cobots, the recognition of objects and grasping of them turned the whole picking and sorting functions in a warehouse into one using advanced technologies. RightHand Robotics, in January 2024, introduced the RightPick 4 system, an enhanced version of piece-picking solution development for warehouse order fulfilment improvement. It is able to handle items up to 25% larger and 50% heavier than those managed by its prototype, significantly reducing human interference. The enhanced AI-based software algorithms, together with an upgraded sensor suite and new hardware design, substantially extended the range of items that can be handled while increasing system autonomy. This technology improves warehouse productivity and reduces mistakes in the picking and packing processes.

Conclusion

The introduction of collaborative robots into warehouse operations is going to be a game changer in the warehouse robotics market, as this will improve productivity, enhance workplace safety, and optimize logistics efficiency. From AI powered order fulfilment to predictive maintenance of warehouse robotics management systems cobots will reshape the future of warehousing Companies will continue to adopt automation, and thus the collaboration among humans and robots will become crucial to drive operational excellence toward quicker deliveries and enable firms to sustain their competitive advantage in this ever-evolving logistics industry.

ABOUT THE AUTHOR

Arunav Dutta is a dedicated and enthusiastic researcher with two years of experience. He has closely monitored several industries, such as Tech, ICT & Media, Robotics, and Electric Vehicles. He offers valuable perspectives and analysis and enjoys sharing his insights through article writing and blogging. Outside of his professional pursuits, he enjoys reading and staying informed about industry developments. The author can be reached at info@nextmsc.com

Arunav Dutta is a dedicated and enthusiastic researcher with two years of experience. He has closely monitored several industries, such as Tech, ICT & Media, Robotics, and Electric Vehicles. He offers valuable perspectives and analysis and enjoys sharing his insights through article writing and blogging. Outside of his professional pursuits, he enjoys reading and staying informed about industry developments. The author can be reached at info@nextmsc.com

Add Comment

Related Blogs

Leaders in Automation Kion, Honeywell, and ABB Influence on the Warehouse Market

Next Move Strategy Consulting forecasts that the Warehouse A...

Unveiling the Top 10 Innovators in the Global Robot Vacuum Cleaner Sector

Next Move Strategy Consulting states that the global robot v...

Shaping the Future: The Transformative Impact of Packaging Robots on Manufacturing Efficiency

Packaging robots include automated machines designed to hand...