Shaping the Future: The Transformative Impact of Packaging Robots on Manufacturing Efficiency

16-Feb-2025

Packaging robots include automated machines designed to handle different packaging tasks such as sorting, packaging, and palletizing in the manufacturing industry. As per the research conducted by Next Move Strategy Consulting, the global packaging robots market was valued at USD 4.77 billion in 2023, and is projected to reach USD 8.66 billion by 2030, growing at a CAGR of 8.9% from 2024 to 2030.

In the present time, the manufacturing industry is undergoing technological transformation. Packaging robots represent a pivotal shift toward automation and stand as vital components in enhancing efficiency, reducing costs, and improving the overall productivity. With technological developments taking place, these robots are becoming indispensable part of manufacturing process. They transform how products are handled, packaged, and shipped. This blog explores the reasons behind the rise of packaging robots, delves into the latest trends in packaging robots, outlines the impact on the manufacturing sector, and highlights the latest launches that are steering this packaging revolution.

The Rise of Packaging Robots

In today’s rapidly evolving industrial landscape, packaging robots are at the forefront of improving efficiency and productivity. Traditional packaging methods heavily relied on human labor that often resulted in inconsistencies, errors, and higher operational expenses. This created a need to adopt automation in packaging methods, providing a combination of speed, accuracy, and cost-effectiveness. Some of the vital reasons behind adopting packaging robots are cited below:

Need for Automation: The need for automation in manufacturing units arises from the necessity to address errors, delays, and high operational costs associated with traditional methods. Automation in packaging robots enhances efficiency and consistency, enabling manufacturers to meet increasing demands and stay competitive. Additionally, they are capable of performing a variety of tasks, such as sorting, picking, packing, and palletizing, marking a significant leap forward in manufacturing process. As per the latest report of the International Federation of Robotics, the global number of operational robots reached a new high in 2022, with a record of 3.9 million installations.

Improving Efficiency: Another primary reason, behind the adoption of packaging robots includes the need to improve operational efficiency. Robots are capable of operating around the clock without breaks, maintaining a consistent pace, and improving operational efficiency.

Enhancing Precision and Consistency: Human labor, while being versatile, is prone to errors, burnout, and inconsistencies, especially during repetitive tasks. It gave rise to the installation of packaging robots in manufacturing units. These robots excel in performing a variety of packaging-related tasks with consistency and precision. They are equipped to handle delicate items, uniform packaging, and maintain excellent quality of each product, leading to higher customer satisfaction and fewer returns.

Latest Trends in Packaging Robots

The packaging robots sector is continuously evolving, with several key trends driving technological innovation in the sector. Notable developments and trends that are shaping the future of automated packaging include:

Collaborative Robots (Cobots)

Collaborative robots, also known as cobots, are revolutionizing the manufacturing plants by working alongside with human workers, enhancing efficiency, safety, and productivity. Unlike traditional robots, cobots are equipped with advanced sensors and safety features, enabling them to operate in close proximity to humans. This collaboration allows manufacturers to enhance packaging process by leveraging the collaborative efforts of robots and manual labor, creating a flexible and efficient production environment.

For instance, Universal Robots launched UR20 cobot that features enhanced payload capacity and reach. This makes it ideal for packaging tasks that require strong handling capabilities. Another notable example can be cited as the launch of Omron TM Series by Omron Automation in India. This cobot is designed to work alongside human operators to fasten speed and safety in various industrial applications, including packaging. The integration of such robots into packaging operations helps businesses improve efficiency, reduce manual labor, and create a safer working environment.

AI and Machine Learning Integration

The integration of artificial intelligence (AI) and machine learning (ML) technologies is significantly enhancing the capabilities of packaging robots. This integration enables robots to learn from their environment, adapt to new tasks, and optimize operational efficiency. A prime example can be cited as the launch of the Robotic Depalletization System, a new robotic AI system by Osaro to improve packaging and palletizing process. The system utilizes advanced AI to optimize handling, arranging, and packaging of goods, enhancing accuracy and efficiency. Additionally, ABB’s new AI powered robot, the IRB 390 FlexPacker, is another vital example of AI-powered packaging robot that utilizes machine learning to optimize high-speed packing, picking, and sorting operations.

Advanced Vision System

Advanced vision systems are revolutionizing the way packaging robots operate and interact with surroundings. Currently, packaging robots are equipped with high-resolution cameras and sophisticated image processing algorithms. These systems enable robots to inspect, identify, sort, pick, and pack products with exceptional accuracy. Vision system plays a vital role in quality control processes, ensuring that only defect-free products are packed and shipped. For example, CRX-10iA, introduced by Fanuc Corporation, is equipped with a state-of-the-art vision system that enhances its ability to perform intricate packaging tasks with high precision.

Flexible and Modular Designs

Manufacturers are increasingly adopting flexible and modular packaging robots that can be easily adjusted to accommodate different packaging tasks with varying weight and size of packaging. These systems offer the versality needed to handle a wide range of products and packaging formats by reducing time and costs associated with retooling. KUKA’S KR AGILUS series, featuring flexible and modular robotics arms, is a notable example of it. This series of robots provides manufacturers with customizable solutions for various packaging applications.

Another notable example includes Yaskawa’s launch of MotoMini. It is one of the smallest industrial robots in the market. Despite its small size, MotoMini is equipped to perform high-speed packaging tasks with great accuracy and efficiency. The robot is 20% faster than other small robots, which help reduce the cycle time and enhance production output in manufacturing units by facilitating various tasks, such as packaging.

Impact on Manufacturing Process

Packaging robots are revolutionizing manufacturing processes by boosting efficiency, enhancing quality control, and optimizing labor. Here is how they are making a difference:

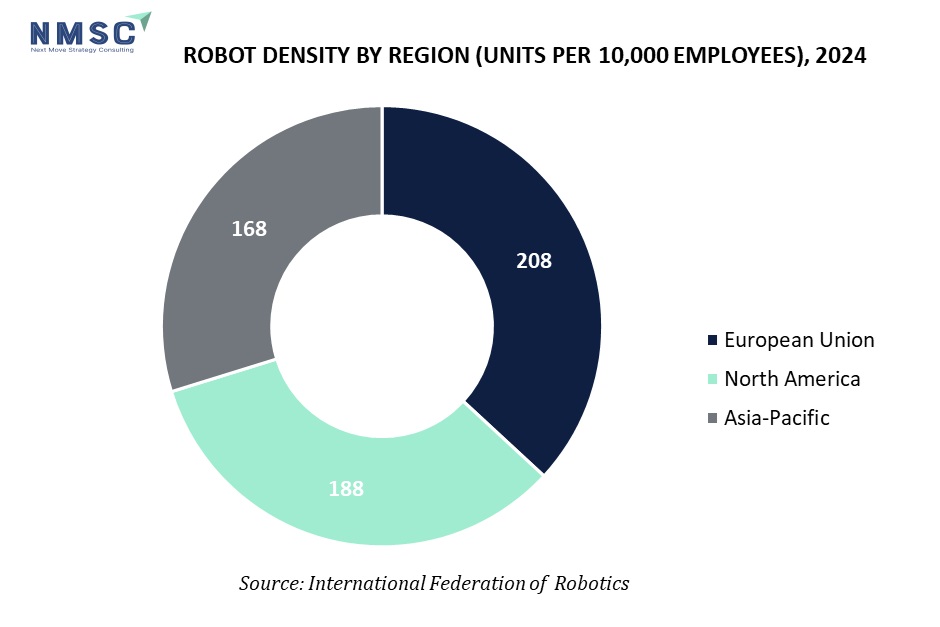

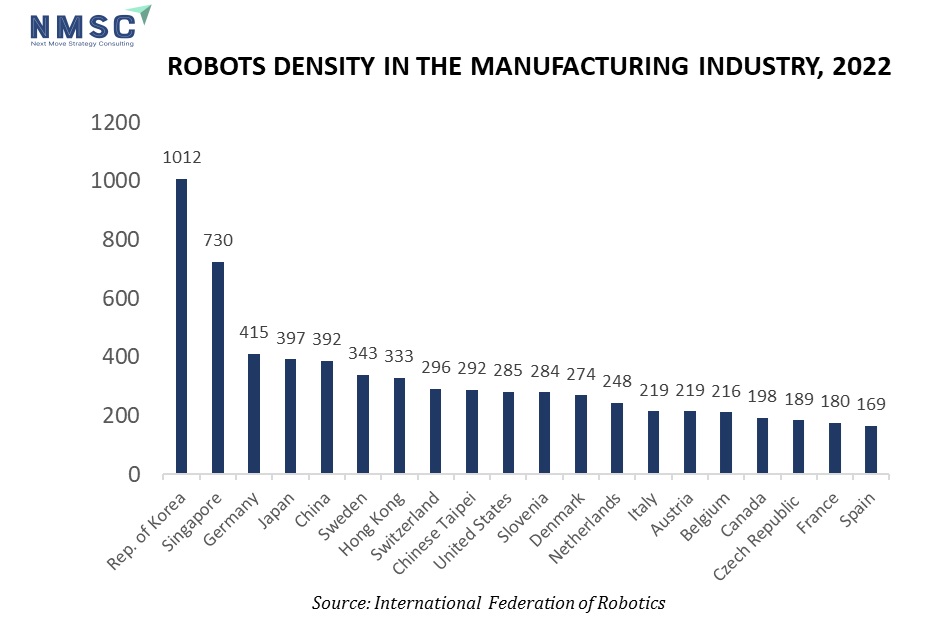

Increased Production Throughout: The adoption of packaging robots significantly enhanced the production capacity by reducing the cycle times and accelerating the packaging process. Packaging robots are capable of performing repetitive tasks at higher speeds than human labor, ensuring a continuous flow of products through the packaging line. This improved efficiency results in higher production volumes and faster time-to-market for manufacturers. This, in turn, leads to high-scale installation of robots in manufacturing plants as depicted in the graph below:

Enhanced Flexibility and Customization: Modern packaging robots are designed to be easily programmable and flexible, allowing manufacturers to quickly adapt to the changing production requirements. This flexibility enables manufacturers to handle different product sizes, shapes, and packaging formats without the need for retooling.

Labor Optimization: Packaging robots perform physically demanding and repetitive tasks, reducing the reliance on manual labor. The adoption of automation in packaging improves worker safety and reduces injuries along with allowing human workers to focus on more complex and value-added activities. The collaborative working of humans and robots is leading to a more efficient and harmonious working environment in the manufacturing units.

Future Prospects of Packaging Robots

Integration with Industry 4.0

The future of packaging robots is closely linked to the broader trends of Industry 4.0, which emphasize the integration of digital technologies and smart manufacturing. Packaging robots will play a crucial role in connected factories, in which they can communicate with other machines, systems, and devices to optimize operations and enable real-time decision making.

Advanced Human-Machine Interfaces (HMIs)

The development of advanced human-machine interfaces (HMIs) is enhancing the usability and functionality of packaging robots. Intuitive touchscreens, voice commands, and augmented reality interfaces make it easier for operators to interact with and control robots. These HMIs streamline the setup and operation of packaging robots, reducing the learning curve and boosting efficiency.

Sustainable Packaging Solutions

As sustainability becomes a top priority for manufacturers, packaging robots are playing a crucial role in promoting eco-friendly practices. Robots optimize packaging processes to minimize material waste, reduce energy consumption, and enhance recycling efforts. By adopting sustainable packaging solutions, manufacturers can meet regulatory requirements, reduce environmental footprint, and appeal to environmentally-conscious consumers.

Conclusion

Packaging robots are at the forefront of manufacturing revolution, transforming the way products are packaged, inspected, and delivered. The integration of advanced technologies such as AI, machine learning, and vision system improved the quality control, efficiency, and adaptability of packaging robots. The integration led to the execution of repetitive tasks with high speed and precision. As these robots became integral to Industry 4.0, they are expected to drive further innovations in automation, reducing the need for manual labor and optimizing operations. The growing adoption of these robots across various industrial sectors, integration of HMIs, and focus on sustainable practices will pave the way for a new era of automation. This will lead to the installation of advanced packaging robots in industrial settings that prioritize efficiency, adaptability, and environmental responsibility. Therefore, by investing in packaging robots and staying abreast of the latest trends and technologies, manufacturers can unlock new levels of productivity and efficiency, ensuing a productive and sustainable future for the industry.

About the Author

Sukanya Dey is a passionate and insightful writer with over three years of experience, she excels in providing clients with in-depth research and valuable insights, helping them navigate complex business challenges. She has a keen interest in various industries, including Healthcare, Manufacturing, Automotive, and ICT & Media. Sukanya strives to offer fresh perspectives and innovative solutions through her comprehensive research. She finds immense joy in weaving her thoughts and ideas into captivating articles and blogs, where her passion for literature and art shines through. In her free time, she enjoys reading books, cooking, filming, often drawing inspiration from these activities for her creative writing endeavors. The author can be reached at info@nextmsc.com

Sukanya Dey is a passionate and insightful writer with over three years of experience, she excels in providing clients with in-depth research and valuable insights, helping them navigate complex business challenges. She has a keen interest in various industries, including Healthcare, Manufacturing, Automotive, and ICT & Media. Sukanya strives to offer fresh perspectives and innovative solutions through her comprehensive research. She finds immense joy in weaving her thoughts and ideas into captivating articles and blogs, where her passion for literature and art shines through. In her free time, she enjoys reading books, cooking, filming, often drawing inspiration from these activities for her creative writing endeavors. The author can be reached at info@nextmsc.com

Add Comment

Related Blogs

Leaders in Automation Kion, Honeywell, and ABB Influence on the Warehouse Market

Next Move Strategy Consulting forecasts that the Warehouse A...

Unveiling the Top 10 Innovators in the Global Robot Vacuum Cleaner Sector

Next Move Strategy Consulting states that the global robot v...

Analysing Japan's $1.87 Billion Consumer AI Market: Major Players And Trends

The Consumer Artificial Intelligence (AI) market is rapidly...