Sustainability in the Antifoaming Agents Market: A Green Revolution for Industrial Applications

05-Mar-2025

The Antifoaming Agents Market is being revolutionized by industries making sustainability a priority in their processes. This green revolution is not just transforming the antifoaming agents market but also bringing it in line with the sustainability objectives of major industries such oil and gas, food and beverage, consumer goods and chemicals.

As industries aim to maximize their production efficiency while reducing the burden on the environment, environment friendly antifoaming agents have become an essential part in ensuring operational effectiveness and regulatory requirements. The worldwide transition toward greener industrial practices driven by consumer pressure and government regulations has inspired innovation in next generation defoamers that are both performance and environment friendly.

Gain exclusive insights into the Anti-foaming Agents Market! Download our latest market share analysis and in-depth report today. Request your free sample now: Click here

This blog will look into how sustainability is transforming the market for antifoaming agents and fueling industrial growth in several sectors.

The Increasing Need for Eco-Friendly Antifoaming Solutions Environmental

Sustainability is increasingly becoming a concern for industries globally that compel businesses to turn to eco-friendly alternatives in production. The antifoaming agent market is evolving accordingly, with the shift away from traditional silicone-based defoamers to biodegradable and plant-based ones that minimizes environmental trace.

To meet these needs, DIC Corporation recently introduced a PFAS-free antifoaming agent for EV lubricating oils that is more effective without the environmental risks of PFAS products. With improved thermal stability and durability, this technology fills the industry's demand for safer alternatives. This change not only helps the planet but also fuels competitive edge, making green advancements a necessity for the future of manufacturing.

Impact of Sustainability on Key Sectors

Oil & Gas Industry: Cleaner Operations with Sustainable Defoamers

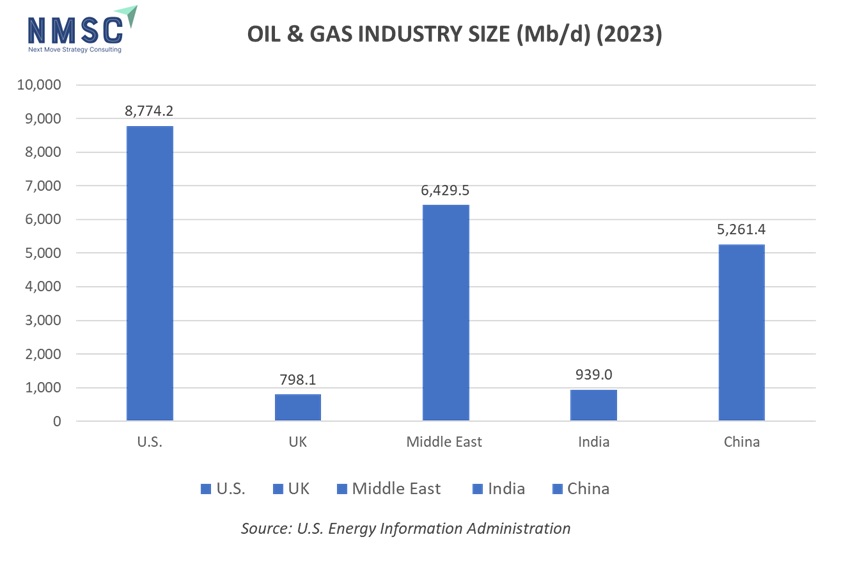

The oil and gas industry utilizes antifoaming agents to manage foam during crude oil extraction and other related application thereby growing need for sustainable antifoaming agents that focus on reducing its environmental impact by using biodegradable defoamers that control foam without toxic leftovers. Sustainable antifoaming agents are gaining popularity to follow stricter environmental rules and ensure safe waste disposal. With global oil production over 90 million barrels per day the need for environment friendly foam control solutions is increasing. Oil and gas companies are turning to green chemistry-based defoamers to boost production while protecting the environment.

Food & Beverage Industry: Maintaining Product Quality with Environmentally Friendly Agents

Creation of foam in food and beverage influences quality and texture, so it is necessary for antifoaming agents to produce consistency and performance. With rising demand from customers for natural and clean-label food products, the demand for eco-friendly food-grade defoamers that can perform well along with being green is growing bigger. Regulatory authorities such as the FDA and EFSA are keen to see the use of sustainable food additives and press manufacturers towards meeting international food safety standards.

One such innovation in this area is MAGRABAR PD-655, a food-grade defoamer produced by Munzing. Formulated for use in food processing operations, it provides better foam control while being biodegradable and genetically modified ingredient-free. Its composition is supportive of clean-labelling trends and is thus an optimal solution for producers looking for sustainable and effective antifoaming agents. With eco-friendly options on the rise, products such as MAGRABAR PD-655 create a new standard of finding performance without compromising on environmental stewardship in the food and beverage sector.

Chemical Industry: Minimizing Environmental Footprint Through Green Defoamers

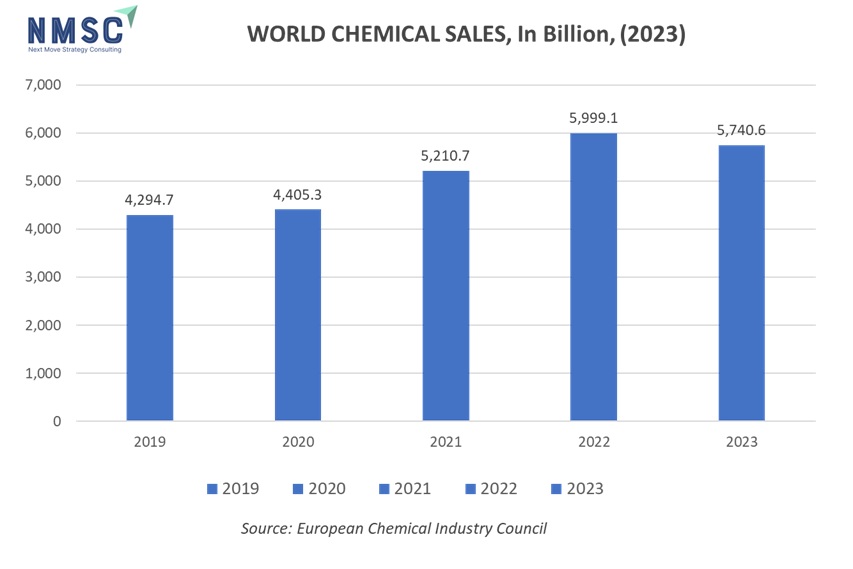

The chemical market, with worldwide sales rising from USD 1,417.84 billion in 2002 to USD 5,795.90 billion in 2023, is increasingly under pressure to embrace sustainability in foam control solutions. Foam creation in production hampers efficiency and, therefore, antifoaming agents are essential. But increasing environmental pressures are driving the use of plant-based and biodegradable defoamers by manufacturers. Such environmentally friendly options boost production, lower emissions, and meet increasingly stringent regulations. With sustainability at the forefront, the need for cleaner foam control solutions keeps rising at an ever-faster pace, propelling innovation throughout the industry.

Companies such as Evonik Industries are bringing with them sustainable alternative silicones in the chemistry space with the help of bio-based defoamers with lower reliance on petrochemical feedstocks. Their ECO line of defoamers rolled out during 2024 complies with ISO 14001 environmental management specifications.

Conclusion: A Greener Future for Antifoaming Agents

The trend toward sustainability in antifoaming agents is not transitory but one that represents an irreversible change rewriting industrial processes through major industries. The application of biodegradable, and free-silicone antifoaming agents is gaining increasing importance with companies looking for lower environmental impacts and compliance with tightening regulations.

Through the implementation of green chemistry and sustainable approaches, companies in sectors such as oil & gas, food & beverages, consumer goods, and chemicals can improve business efficiency, reduce waste, and cater to environmentally conscious consumers and regulatory agencies. The future of the antifoaming agents market is definitely green, and firms that invest in green solutions today will be poised for success in the years to come.

ABOUT THE AUTHOR:

Baishali Sengupta is a dedicated Research Associate with more than 3 years of experience in the market research field. Known for her keen analytical skills and meticulous attention to detail, she excels in distilling complex data into actionable insights. Baishali combines a passion for research with a commitment to delivering high-quality, accurate information. Her proactive approach and enthusiasm for continuous learning make her a valuable asset in understanding market trends and driving informed decision-making. The author can be reached at info@nextmsc.com

Baishali Sengupta is a dedicated Research Associate with more than 3 years of experience in the market research field. Known for her keen analytical skills and meticulous attention to detail, she excels in distilling complex data into actionable insights. Baishali combines a passion for research with a commitment to delivering high-quality, accurate information. Her proactive approach and enthusiasm for continuous learning make her a valuable asset in understanding market trends and driving informed decision-making. The author can be reached at info@nextmsc.com

Add Comment

Related Blogs

Global Leaders in Anti-Foaming Agents: How Major Companies are Innovating for Sustainability

According to Next Move Strategy Consulting, the global Anti-...

The Transformative Power of Botulinum Toxin in the Healthcare and Cosmetic Industry

Introduction The Botulinum Toxin Market has experienced r...

Green Hydrogen: A Promising Future of Renewable Energy

Introduction Decarbonization of the planet is one of the targets that nations...