How Aerospace Coatings Are Evolving in 2024

Published: 2025-09-15

Introduction

The aerospace industry is a pinnacle of human achievement, soaring above the earth's boundaries and expanding our horizons. Yet, behind the aerodynamic designs and technological marvels lies a critical component often overlooked–aerospace coatings. These coatings are not just cosmetics; they play a vital role in ensuring aircraft safety, performance, and longevity. The aerospace coatings market has witnessed significant trends and developments reshaping the industry in recent years.

The aerospace coatings market is a dynamic sector with coatings for various aerospace applications. These coatings are specifically designed to withstand extreme flight conditions, including rapid altitude changes, temperature fluctuations, and exposure to elements. Moreover, they contribute to the aerodynamic efficiency and aesthetics of the aircraft. The aerospace coatings market encompasses a range of products, ranging from primers and topcoats to specialty coatings for specific applications. This article explores the key technology trends reshaping the aerospace coatings industry.

Recent Trends in the Aerospace Coatings Market

Eco-Friendly Coatings

One of the most prominent and impactful trends in the aerospace coating market is the notable shift toward eco-friendly coatings. This transformation is a direct response to the aviation industry's increasing scrutiny, due to its environmental impact, particularly concerning greenhouse gas emissions and carbon footprint. With a growing emphasis on sustainability and a commitment to reducing the environmental footprint of aerospace operations, aerospace coatings manufacturers are stepping up to address this challenge.

In the quest for eco-friendliness, various manufacturers are dedicated to developing and offering environmentally-sustainable coatings that align with stringent environmental standards and regulations. A key aspect of this transformation is the adoption of water-based coatings, which substantially reduce the usage of harmful chemicals and solvents.

Moreover, lower volatile organic compound (VOC) coatings are gaining considerable traction. PPG, a coatings and specialty products company, launched its new line of low-VOC exterior topcoats for the aviation industry. These topcoats are formulated to provide durable and environmentally friendly finishes for aircraft exteriors.

They meet stringent environmental standards while offering excellent color and gloss retention. These coatings not only adhere to strict environmental regulations but also provide additional advantages by reducing the overall weight of aircraft. The weight reduction contributes to enhanced fuel efficiency, which is a pivotal factor in the aviation industry's commitment to reducing its environmental impact.

This shift toward eco-friendly coatings highlights the industry's proactive efforts to reduce carbon footprint while enhancing operational efficiency and compliance with evolving environmental regulations. As this trend continues to grow, it will significantly influence the future direction of the aerospace coatings market, making eco-friendly coatings an integral component of the industry's strategy for a more sustainable aviation future.

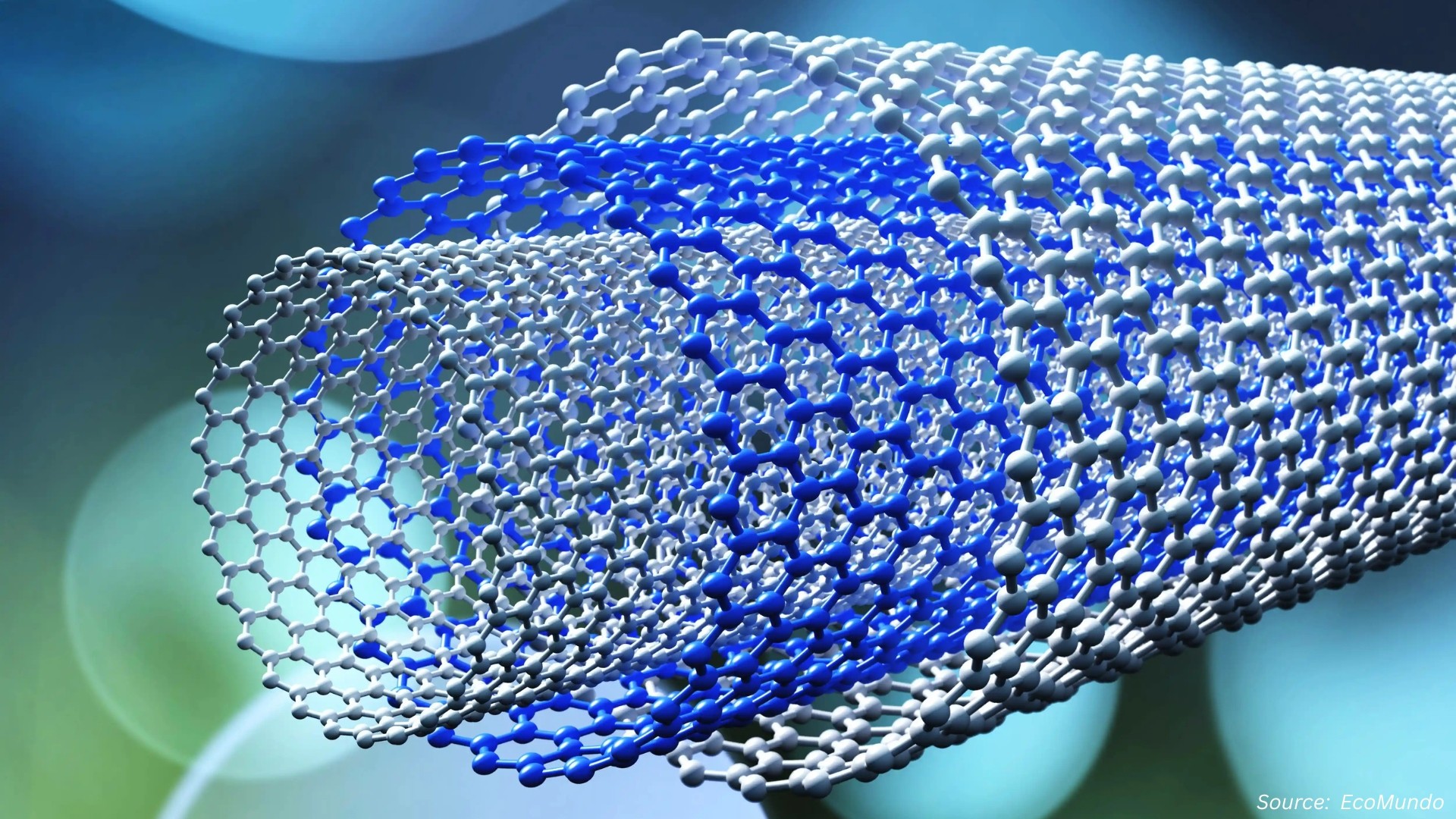

Advanced Nanotechnology

Nanotechnology is emerging as a game-changer within the aerospace coatings industry. It introduces a new dimension of effectiveness by leveraging the unique properties of nanomaterials. This innovation offers several critical advantages, primarily in enhancing the protection and performance of aerospace coatings.

One of the primary benefits of incorporating nanomaterials into aerospace coatings is their exceptional ability to shield against environmental elements, such as the detrimental effects of ultraviolet (UV) radiation and corrosion. These coatings form an ultra-thin protective layer that acts as a barrier, significantly extending the lifespan of the aircraft's exterior. By effectively repelling UV radiation, they preserve the aircraft's appearance and structural integrity, reducing the need for frequent maintenance and repainting.

Moreover, nanocoatings exhibit remarkable super-hydrophobic properties, making them highly effective in preventing water accumulation and ice formation on the aircraft's surface. This attribute is particularly crucial for ensuring the safety and performance of aircraft, especially in adverse weather conditions. By preventing ice accumulation, nanocoatings contribute to aerodynamic efficiency, reducing fuel consumption and maintenance-related downtime.

Lufthansa Technik, an aviation technology provider, collaborated with an engineering simulation software company ANSYS. The collaboration aims to develop and certify their AeroSHARK technology. This cutting-edge technology uses nanocoatings and advanced materials at the nanoscale to improve the aerodynamics and fuel efficiency of aircraft. By employing nanotechnology, AeroSHARK is designed to reduce drag on the aircraft's surface, leading to decreased fuel consumption and emissions.

The application of nanotechnology in aerospace coatings also translates to coatings with an extended lifespan. These coatings are inherently more durable, resistant to wear and tear, and better equipped to withstand the rigors of aviation. As a result, they reduce the frequency of maintenance cycles and the associated costs.

This efficiency improves the operational economics of airlines and aerospace manufacturers and minimizes the environmental impact by reducing the consumption of resources required for maintenance activities. These nanocoatings are set to redefine the standards for aerospace protection and performance, making them a key driving force in the evolving aerospace coatings market.

Thermal Barrier Coatings

Thermal Barrier Coating (TBC) is engineered to act as an insulating layer, providing crucial protection to critical components within aircraft engines. Their primary function is to shield these essential parts from the extreme heat generated during engine operation. As aircraft engines evolve and become more powerful than before, the temperatures they cause are progressively higher. This necessitates advanced solutions to maintain optimal engine performance and longevity.

One of the standout features of TBCs is their exceptional ability to enhance the durability of aircraft engines. By serving as insulators, they effectively mitigate the adverse effects of extreme heat on engine components. This, in turn, extends the lifespan of critical engine parts, reducing the need for frequent maintenance and replacements. The enhanced durability offered by TBCs benefits the aerospace industry by lowering maintenance costs and bolsters the reliability and safety of aircraft, which is paramount in the aviation sector.

Furthermore, the implementation of TBCs delivers substantial advantages in terms of fuel efficiency. These coatings safeguard engines against extreme temperatures, enabling engines to operate at higher temperatures without incurring damage. This improved thermal resistance and durability enhance engine efficiency, reduce fuel consumption, and lower operational costs. It presents a win-win scenario in which airlines and the environment benefit from improved fuel efficiency and reduced emissions.

Smart Coatings

The introduction of smart coatings into the aerospace industry represents a leap forward in how aircrafts are managed and maintained. It embraces the principles of Industry 4.0 and the Internet of Things (IoT), ushering in a new era of data-driven decision-making and predictive maintenance.

As a result, the aerospace sector benefits from improved operational efficiency, reduced maintenance costs, and enhanced safety. This exciting development in aerospace coatings underscores the industry's commitment to harnessing the power of technology to achieve improved performance, reliability, and sustainability.

One of the standout features of smart coatings is their capacity to actively monitor critical aspects of an aircraft's performance, including its structural health, temperature, and stress levels. Equipped with state-of-the-art sensors and microelectronics, these coatings continuously collect data in real time.

This real-time data collection serves as a valuable source of information for aircraft operators, offering insights into the aircraft's condition and performance during flight. Such monitoring can identify issues early, allowing operators to address any emerging concerns proactively.

One of the most significant advantages of smart coatings is their contribution to predictive maintenance. By continuously collecting and analyzing data, these coatings provide aircraft operators with invaluable insights into the health of the aircraft. This real-time data-driven approach empowers operators to predict when maintenance or repairs are required, preventing unexpected breakdowns and reducing costly downtime. This proactive maintenance strategy enhances the reliability and safety of aircraft and significantly improves operational efficiency.

In a related development, Industrial Nanotech, Inc. introduced a new subsidiary focused on smart coatings and revealed an ambitious plan to collaborate with over 300 independent sales representatives. They aim to bring patent-pending self-reporting coatings, a first-of-its-kind innovation, to the market with a substantial industrial footprint exceeding 2.5 billion.

This strategic move marks a significant development in the smart coating sector and demonstrates the company's commitment to expanding the usage of cutting-edge self-reporting coatings in various industries. This collaboration aligns with the broader trend of adopting smart coatings across industries and highlights the growing interest in these innovative technologies. Together, these developments signify a promising future for smart coatings in enhancing operational efficiency and sustainability. With smart coatings, the possibilities are endless, and the aerospace and industrial sectors are on the cusp of a more intelligent and efficient era.

Conclusion

The aerospace coating market is undergoing significant transformation, largely influenced by emerging trends and ongoing developments that address the dynamic needs of the aviation industry. While the sector is resolutely committed to achieving environmental sustainability and technological progress, the evolution of aerospace coatings is multifaceted. Notably, the rise of eco-friendly coatings reflects a collective effort to minimize the environmental footprint, emphasizing a commitment to sustainability.

Concurrently, the integration of advanced technologies such as nanotechnology and smart coatings is reshaping the landscape by enhancing performance, safety, and efficiency. Nanotechnology brings forth coatings that shield against environmental elements and contribute to aerodynamic efficiency. While smart coatings, ushering in the era of Industry 4.0, actively monitor aircraft health, enabling predictive maintenance and improving operational efficiency.

Additionally, thermal barrier coatings (TBCs) play a crucial role in enhancing engine durability, reducing maintenance costs, and boosting fuel efficiency. As these diverse trends unfold, they collectively redefine the future of the aerospace coatings market. In this broader mission of realizing sustainable aviation practices, aerospace coatings are instrumental, aligning with the industry's vision for a more eco-conscious and technologically advanced future.

About the Author

Saurav Sarkar is an accomplished researcher and writer with over three years of experience in conducting thorough research. His passion for exploring various subjects and delving into in-depth analysis has led him to develop a keen understanding of research nuances. He remains committed to staying current with the latest market trends, recognizing their impact on businesses and society.

Saurav Sarkar is an accomplished researcher and writer with over three years of experience in conducting thorough research. His passion for exploring various subjects and delving into in-depth analysis has led him to develop a keen understanding of research nuances. He remains committed to staying current with the latest market trends, recognizing their impact on businesses and society.

About the Reviewer

Sanyukta Deb is a seasoned Content Writer and Team Leader in Digital Marketing, known for her expertise in crafting online visibility strategies and navigating the dynamic digital landscape. With a flair for developing data-driven campaigns and producing compelling, audience-focused content, she helps brands elevate their presence and deepen user engagement. Beyond her professional endeavors, Sanyukta finds inspiration in creative projects and design pursuits.

Sanyukta Deb is a seasoned Content Writer and Team Leader in Digital Marketing, known for her expertise in crafting online visibility strategies and navigating the dynamic digital landscape. With a flair for developing data-driven campaigns and producing compelling, audience-focused content, she helps brands elevate their presence and deepen user engagement. Beyond her professional endeavors, Sanyukta finds inspiration in creative projects and design pursuits.

Add Comment