Warehouse Automation Market by Component (Hardware and Software, and Services), by Application (Picking and Packing, Storage and Retrieval, Transportation and Distribution, Sorting and Handling, and Inventory Management), and By Industry Vertical (E-commerce and Retail, Food and Beverage, Pharmaceuticals and Healthcare, Automotive, Electronics and Electricals, Third-Party Logistics (3PL), and Others) – Global Opportunity Analysis and Industry Forecast 2024–2030

Industry: ICT & Media | Publish Date: 01-Mar-2025 | No of Pages: 627 | No. of Tables: 440 | No. of Figures: 385 | Format: PDF | Report Code : IC443

US Tariff Impact on Warehouse Automation Market

Trump Tariffs Are Reshaping Global Business

Market Overview

The global Warehouse Automation Market size was valued at USD 23.84 billion in 2023, and is projected to reach USD 54.60 billion by 2030 at a CAGR of 11.7% from 2023 to 2030.

Warehouse automation refers to the use of technology and machinery to optimize processes & operations such as material handling, picking & packing, and inventory management in a warehouse. It includes use of automated systems such as conveyor systems, automated storage & retrieval systems, robotic picking & packing systems, automated guided vehicles, and robots. These systems are designed to automate tasks such as receiving, storage, retrieval, loading & unloading, and shipping of goods. Warehouse automation solutions are used in a variety of industries including retail, e-commerce, manufacturing, and logistics.

One of the advantages of implementing warehouse automation is that it reduces reliance on manual labor, allowing workers to concentrate on more critical activities. It also enhances safety by automating dangerous tasks such as heavy lifting. In addition, another advantage is real-time inventory tracking, which facilitates informed decision-making for businesses. Moreover, warehouse automation helps organizations optimize their operations and enhance their ability to compete in the market.

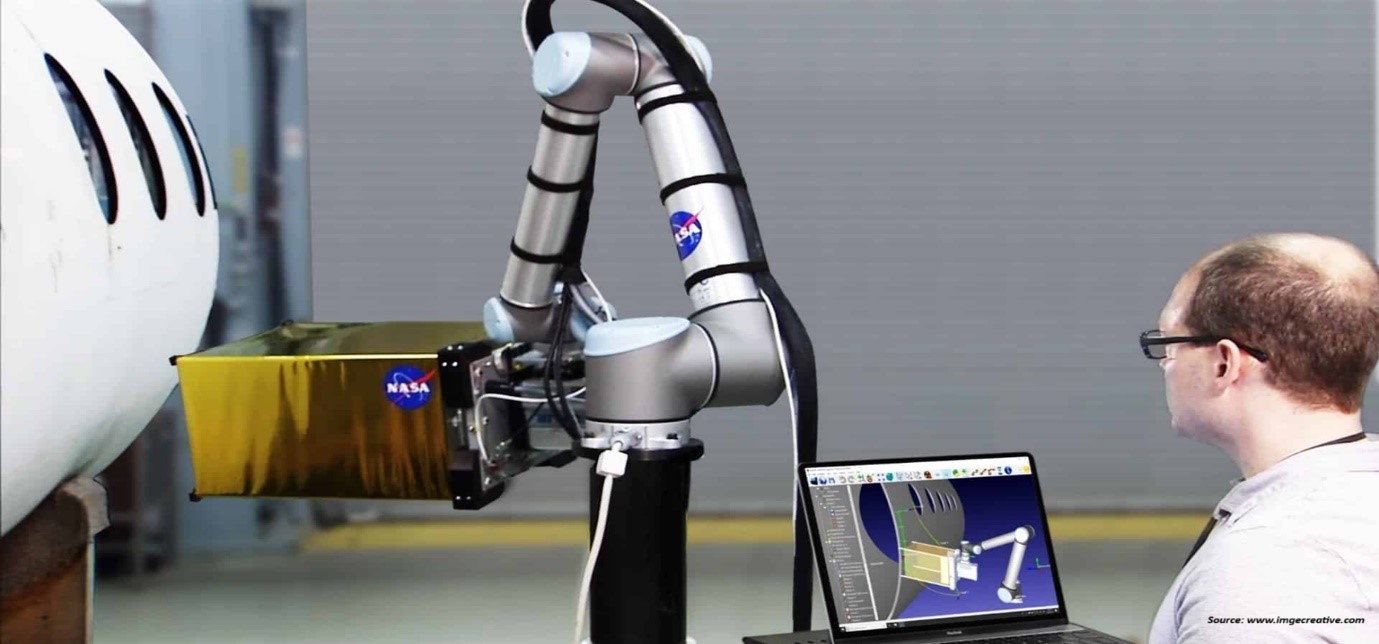

The Rise in the Adoption of Robotics in Warehousing Propels the Market Growth

The rise in the adoption of robotics in warehousing is driven by the need for increased efficiency, productivity, and cost savings. Robotic technology offers warehouses the ability to automate repetitive and physically demanding tasks, reducing labor costs, and improving accuracy. It provides a highly efficient and flexible solution to automate various warehouse tasks such as material handling, order picking, and packing.

Deployment of robots in warehouses also leads to improved safety as they can perform dangerous tasks such as heavy lifting and hazardous material handling. In addition, robots can work 24/7 without breaks, leading to increased output and reduced periods of inactivity, further driving the warehouse automation market growth.

Growth in E-commerce and Online Retail Industry Fuels the Growth of the Market

Growth in the e-commerce sector and online retail has resulted in a higher demand for automated warehousing solutions that can efficiently handle order fulfillment processes. Automated warehousing solutions, such as warehouse management systems and automated storage & retrieval systems help companies to improve their productivity and reduce the risk of stock shortages or excess inventory. Rise in need for efficient order fulfillment to meet consumer expectations propels growth of the warehouse automation market.

High Cost and Complexity Associated with the Setup of Warehouse Automation Hinder the Market Growth

The high cost and complexity of automated systems are the primary reasons that limit their use in warehouses. These systems are expensive to buy, install, and maintain, making it difficult for smaller companies or those with limited budgets to afford them. Moreover, it requires specialized expertise to operate and maintain, which can be a barrier for companies that lack the necessary technical skills and resources. Thus, these factors hinder the growth of the market.

Emergence of Industry 4.0 Creates an Opportunity for Advancements in the Market

The emergence of Industry 4.0 presents a significant opportunity for the warehouse automation market. This latest stage of industrial revolution focuses on automation, interconnectivity, real-time data, and machine learning. Adoption of smart digital technologies such as AI, ML, and IoT in manufacturing & supply chain management has created a better-linked ecosystem for businesses where information and data can be easily shared & analyzed in real time.

It also includes use of mobile & collaborative robots, which are connected to one another and play a crucial role in factories, warehouses, and production facilities. Robots in warehouses enhance digital integration and enable efficient & flexible workflows. Therefore, it is projected that adoption of Industry 4.0 would present significant opportunities for market players that operate in the warehouse automation market.

North America Holds a Major Share in the Warehouse Automation Market

North America holds the largest share in the warehouse automation market, and is expected to continue its dominance during the forecast period. This is attributed to factors such as advancements in technology, need for improved efficiency & productivity, along with increasing availability and affordability of automated systems across this region.

Globally, the U.S. ranked 7th in robot density in the car industry in 2021 as reported by the International Federation of Robotics. In the U.S. automotive industry, 1,287 robots were installed per 10,000 employees in 2021. The automotive industry utilizes robots in various applications while manufacturing vehicles including assembly and product handling in warehouses, which, in turn, drives growth of the warehouse automation market.

Moreover, presence of regional robot manufacturers such as Destaco, Fetch Robotics Inc., Applied Robotics Inc., and RobotWorx, Inc. that are adopting product launch as their key developmental strategy that further contributes toward growth of the market in this region. For instance, in January 2021, Fetch Robotics launched its new PalletTransport1500, an autonomous mobile robot (AMR) designed specifically to replace forklift trucks in warehouses. The new robot has the capability to pick up and drop off loaded pallets up to 1136 kg, as well as to eliminate humans from the pallet movement equation.

Asia-Pacific is Growing Steadily in the Warehouse Automation Market

Asia-Pacific is expected to show a steady rise in the warehouse automation market share, owing to various government initiatives to implement automation and robotics in this region. Countries such as South Korea, India, and Thailand are integrating robots with human workers and investing in automation to improve their warehouse & logistics operations. Increase in emphasis on automation across these countries propels growth of the industry.

For instance, in January 2022, the government of South Korea announced that it would permit robots on public roads for delivery services in 2023. This initiative is expected to significantly enhance its logistics and warehouse operations, leading to increase in adoption of automation technologies.

Moreover, there is a rise in demand for warehouse automation systems in Japan, which is the world's top exporter of robots. Its leading position in robot manufacturing contributes toward growth of the warehouse automation market. According to the International Federation of Robotics (IFR), there were 4,720 industrial robot installations in 2021, indicating a rise in adoption of automation technologies in manufacturing and logistics sectors in Japan.

Competitive Landscape

The warehouse automation industry trends include various market players such as Honeywell International Inc., Kion AG, Vanderlande Industries Inc, SSI Schaefer (Pvt), Daifuku Co. Ltd, Material Handling Systems Global, Omron Corporation, Schneider Electric SE, ABB Limited, TGW Logistics Group, Toshiba Corporation, Knapp AG, Locus Robotics, Yaskawa Electric Corporation, Kuka AG. These market players are adopting several strategies such as product launches, partnerships, and business expansions across various regions to maintain their dominance in the market.

For instance, in December 2022, ABB launched "ABB SWIFT CRB 1300" industrial collaborative robot. This new robot was suitable for performing a wide variety of applications ranging from machine tending and palletizing to pick-and-place operations in warehouses. Also, in April 2022, Vanderlande launched an advanced automated picking robot to its Smart Item Robotics (SIR) warehouse solution portfolio. This robot featured gripping technology, along with sophisticated vision and control suitable for warehouses and distribution centers handling general merchandise products.

Moreover, in September 2021, Kion AG announced a collaboration with Fraunhofer IML to develop a new generation of autonomous transport swarm robots for warehouse management. The collaboration enabled to develop of LoadRunner, an AI-based robot to pave the way for a new generation of autonomous transport vehicles as well as revolutionize intralogistics. The collaboration among key players is expected to benefit customers with advanced warehouse automation products during the forecast period.

Warehouse Automation Market Key Segments

By Component

-

Hardware

-

Automated Storage and Retrieval Systems (AS/RS)

-

Conveyors and Sortation Systems

-

Autonomous Mobile Robots (AMRs)

-

Automated Guided Vehicles (AGVs)

-

Palletizing and Depalletizing Systems

-

Others

-

-

Software

-

Warehouse Management Systems (WMS)

-

Warehouse Control Systems (WCS)

-

Inventory Management Software

-

Order Management Software

-

Others

-

-

Services

-

Consulting and System Integration

-

Maintenance and Support

-

By Application

-

Picking and Packing

-

Storage and Retrieval

-

Transportation and Distribution

-

Sorting and Handling

-

Inventory Management

By Industry Vertical

-

E-commerce and Retail

-

Food and Beverage

-

Pharmaceuticals and Healthcare

-

Automotive

-

Electronics and Electricals

-

Third-Party Logistics (3PL)

-

Others

By Geography

-

North America

-

U.S

-

Canada

-

Mexico

-

-

Europe

-

UK

-

Germany

-

France

-

Italy

-

Spain

-

Denmark

-

Netherlands

-

Finland

-

Sweden

-

Norway

-

Russia

-

Rest of Europe

-

-

Asia-Pacific

-

China

-

Japan

-

India

-

Australia

-

South Korea

-

New Zealand

-

Taiwan

-

Indonesia

-

Singapore

-

Rest of Asia-Pacific

-

-

RoW

-

Latin America

-

Middle East

-

Africa

-

Key Players

-

Honeywell International Inc.

-

Kion AG

-

Vanderlande Industries Inc

-

SSI Schaefer (Pvt)

-

Daifuku Co. Ltd

-

Material Handling Systems Global

-

Omron Corporation

-

Schneider Electric SE

-

ABB Limited

-

TGW Logistics Group

-

Toshiba Corporation

-

Knapp AG

-

Locus Robotics

-

Yaskawa Electric Corporation

-

Kuka AG

Report Scope and Segmentation

|

Parameters |

Details |

|

Market Size in 2023 |

USD 23.84 Billion |

|

Revenue Forecast in 2030 |

USD 54.60 Billion |

|

Growth Rate |

CAGR of 11.7% from 2024 to 2030 |

|

Analysis Period |

2023–2030 |

|

Base Year Considered |

2023 |

|

Forecast Period |

2024–2030 |

|

Market Size Estimation |

Billion (USD) |

|

Growth Factors |

|

|

Countries Covered |

28 |

|

Companies Profiled |

15 |

|

Market Share |

Available for 10 companies |

|

Customization Scope |

Free customization (equivalent up to 80 analysts working hours) after purchase. Addition or alteration to country, regional & segment scope. |

|

Pricing and Purchase Options |

Avail customized purchase options to meet your exact research needs. |

Speak to Our Analyst

Speak to Our Analyst