Discover The Latest Trends Transforming Warehousing

17-Sep-2024

Introduction

The evolution of warehousing has progressed significantly beyond manual labour and paper-based inventory systems. In the age of technology, the modern warehouse is undergoing a significant transformation. From Mobile Robots as a Service (RaaS) to the emergence of humanoid robots and the implementation of edge computing, technology is revolutionizing the way warehouses operate, making them more efficient, accurate, and adaptable. This article explores how these innovations are reshaping the warehousing landscape across the globe.

Emergence of Humanoid Robot

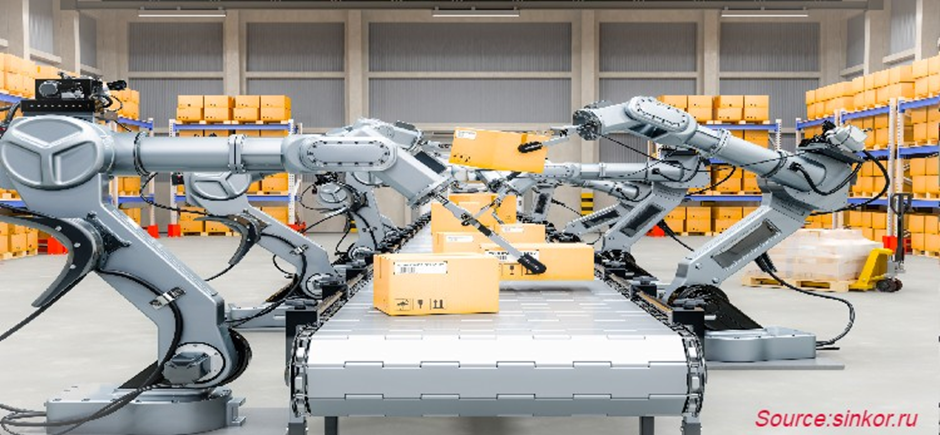

The emergence of humanoid robots in the warehousing industry represents a notable technological advancement that is reshaping how warehouses operate. These robots, designed to replicate human physical attributes to some extent, are gaining popularity for their versatility and capacity to undertake a wide range of complex tasks.

Humanoid robots are being employed within the warehouse environment, in roles that demand a level of skill and decision-making capabilities that exceed the capabilities of traditional robotic systems. Below are several key ways in which humanoid robots are making their mark in warehousing:

Picking and Packing: Humanoid robots excel at tasks such as picking and packing products. They can carefully select items from shelves, place them in appropriate containers, and arrange them efficiently with their specialised limbs and advanced gripping mechanisms. This is particularly valuable for warehouses dealing with a wide variety of products that may have different shapes, sizes, and fragility.

Quality Checks: Humanoid robots are also highly effective at performing quality checks on items. They can inspect products for defects, ensuring that only high-quality items are shipped to customers. This capability is crucial for maintaining product quality standards and customer satisfaction.

Handling Delicate Items: Delicate or fragile items often pose a challenge for traditional robotic systems, as their rigid, mechanical arms can inadvertently damage these products. Humanoid robots, on the other hand, are better equipped to handle such items delicately and with care, reducing the risk of damage.

Collaboration with Human Workers: Humanoid robots are designed to interact with human workers seamlessly. They can understand human gestures and instructions, making them effective collaborators in mixed human-robot teams. This collaboration enhances the efficiency of warehouse operations, as these robots can take on tasks that require human-like understanding and decision-making, thus freeing up human workers for more complex or strategic roles.

Moreover, the integration of humanoid robots into warehousing is has a strong focus on safety as they are equipped with advanced collision avoidance systems and other safety features to ensure they can operate in close proximity to human workers without posing any risks. This commitment to safety enables human and humanoid robot workers to coexist harmoniously in the same workspace, further improving overall warehouse efficiency.

In March 2023, Agility Robotics showcased its latest version of the humanoid robot called Digit, at ProMat 2023 in the U.S. Digit is a human-centric, multi-purpose robot designed for logistics work in warehouse environment. The robot was showcased in a replica warehouse work cell, where it performed fully autonomous live demonstrations of pick and place operations. Also, in September 2022, Agility Robotics announced the opening of a new manufacturing facility in Oregon, US. This new facility will be able to produce more than 10,000 humanoid robots a year which are specifically designed for warehouse operations.

Edge Computing for Real-time Responsiveness in warehouse robots

Edge computing represents a revolutionary leap in the field of robotics, elevating the capabilities and responsiveness of software’s used in industrial robots including warehouse robots. In contrast to conventional setups reliant on centralized computing, edge computing relocates data processing closer to the source of the data, allowing robots to process information locally. This reduction in latency empowers robots to make real-time decisions, even in the absence of constant internet connectivity.

The real-time responsiveness made possible by edge computing carries transformative implications across various applications, as it enables robots to swiftly adapt to changing warehouse operations and optimize processes based on sensor inputs. Furthermore, local data processing enhances privacy and security, reducing reliance on cloud-based services and mitigating potential risks.

In November 2022, Siemen expanded its Industrial Edge platform with OT and IT integration. This platform is equipped with edge devices, edge apps, edge connectivity, and a device management system, which is pivotal for optimizing warehouse robot performance. Moreover, It reduces latency, ensuring these robots can efficiently process large volumes of data in real-time. This real-time decision-making capability is essential in dynamic warehouse settings, allowing robots to navigate, adapt, and coordinate tasks seamlessly, improving their overall efficiency and responsiveness in a rapidly changing operational environment.

Mobile Robots as a Service (RaaS)

Mobile Robots as a Service (RaaS) is revolutionizing the warehousing industry by offering a flexible and cost-effective approach to integrating robotics into the warehouse workflow. RaaS is fundamentally a subscription-based model, and it represents a shift away from the traditional method of purchasing robotic systems outright. This model is specifically advantageous for smaller businesses, startups, or those with limited capital and resources, as it eliminates the need for a substantial upfront investment in robotic hardware and software. Instead of buying expensive robotic equipment, businesses can lease the robotic systems they require for their specific needs.

RaaS robots come equipped with a sophisticated array of sensors, coupled with advanced artificial intelligence algorithms. This combination enables them to autonomously navigate complex warehouse environments with precision. They can efficiently and safely interact with their surroundings, making them ideal candidates for a variety of tasks within the warehousing setting.

Some of the core tasks RaaS robots excel in include material handling, inventory management, and order fulfilment. These robots are designed to be adaptable, a characteristic that makes them particularly valuable in warehouses with dynamic workloads and seasonal fluctuations in demand. With the ability to be easily reprogrammed and reconfigured, they can seamlessly transition from one task to another, offering unprecedented agility in warehouse operations.

One of the most significant benefits of RaaS is its role in ensuring that warehouses constantly have access to the latest and most advanced robotic technology. In the ever-evolving field of robotics, keeping pace with technological advancements can be a formidable challenge. Traditional robot ownership faces issues such as being stuck with outdated equipment, requiring expensive upgrades or replacements. In contrast, the subscription-based nature of RaaS guarantees that warehouses are always equipped with state-of-the-art robots.

This continuous access to cutting-edge technology results in increased efficiency, as the latest robotic systems are optimized for the most efficient operation. Additionally, lower operational costs associated with RaaS, compared to the maintenance and upgrading expenses of owned robotic systems benefits the small business. Using Raas, businesses can allocate resources more effectively and reduce the total cost of ownership.

In December 2022, Aro launched a new Robot as a Service (RaaS) offering for any robotics original equipment manufacturer (OEM). This initiative represented a growing trend in the warehouse robotics market, where RaaS transformed how businesses adopted and used robotic systems in their operations. This new approach simplified the integration of robots into warehouse environments, making the technology more accessible and cost-effective. As more companies embraced RaaS solutions, it is expected to drive the growth and expansion of the warehouse robotics market, paving the way for increased automation and efficiency in logistics and fulfilment operations.

Conclusion

The modern warehousing industry is being transformed by a wave of technological innovations. Mobile Robots as a Service (RaaS) offers cost-effective and adaptable automation, humanoid robots bring a new level of dexterity and interaction with humans, and edge computing ensures real-time responsiveness and predictive maintenance for warehouse robots. These advancements are reshaping the warehousing landscape, making it more efficient, agile, and capable of meeting the increasing demands of modern commerce. As technology continues to advance, the future of warehousing promises even more exciting developments and improvements.

About the Author

Shankar Nishant is a researcher at Next Move Strategy Consulting with a cumulative experience of more than four years. Shankar is enthusiastic about new technology, enjoys working with diverse global clients, and has delivered numerous market reports in multiple domains. He can be reached at info@nextmsc.com

Shankar Nishant is a researcher at Next Move Strategy Consulting with a cumulative experience of more than four years. Shankar is enthusiastic about new technology, enjoys working with diverse global clients, and has delivered numerous market reports in multiple domains. He can be reached at info@nextmsc.com

Add Comment

Related Blogs

Leaders in Automation Kion, Honeywell, and ABB Influence on the Warehouse Market

Next Move Strategy Consulting forecasts that the warehouse a...

Unveiling the Top 10 Innovators in the Global Robot Vacuum Cleaner Sector

Next Move Strategy Consulting states that the global robot v...

Shaping the Future: The Transformative Impact of Packaging Robots on Manufacturing Efficiency

Packaging robots include automated machines designed to hand...