Collaborative Robot Market by Component (Hardware and Software), by Payload Capacity (Up to 5 Kg, Between 5 Kg and 10 Kg, More than 10 Kg), by Application (Handling, Assembling & Disassembling, Welding & Soldering, Dispensing, Processing, and Others), and by Industry Verticals (Automotive, Electronics, Metals & Machining, Plastics & Polymers, Food & Beverages, Furniture & Equipment, Healthcare, and Other Industries)– Global Opportunity Analysis and Industry Forecast, 2024–2030

Industry: ICT & Media | Publish Date: 07-Mar-2025 | No of Pages: 1143 | No. of Tables: 288 | No. of Figures: 253 | Format: PDF | Report Code : IC411

US Tariff Impact on Collaborative Robot Market

Trump Tariffs Are Reshaping Global Business

Market Overview

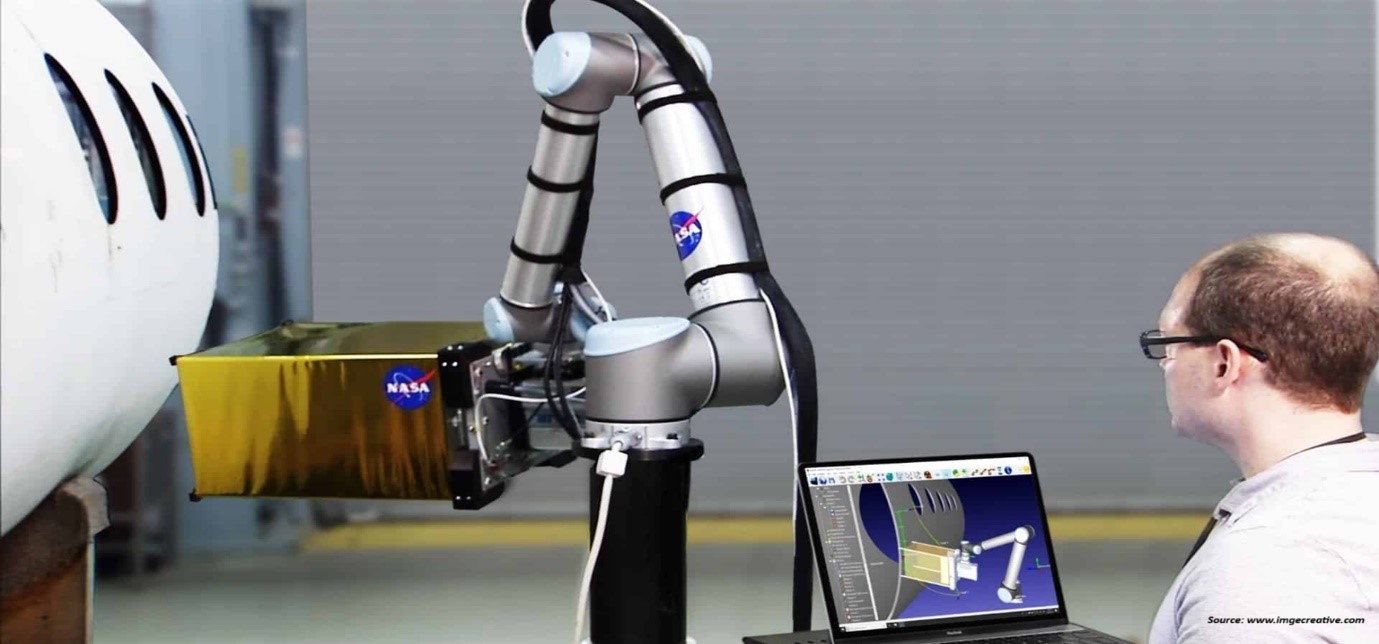

The global Collaborative Robot (cobots) Market size was valued at USD 1.77 billion in 2023 and is expected to reach USD 12.71 billion by 2030, with a CAGR of 32.6% from 2024 to 2030. Collaborative robots, commonly known as cobots, refer to a specialized segment within the industrial robotics market that focuses on the development and deployment of robots designed to work alongside humans collaboratively and interactively.

Unlike traditional industrial robots, which are often confined to isolated spaces or require safety barriers, cobots are designed to operate safely in shared workspaces, fostering direct cooperation with human workers. These robots find applications across diverse industries, such as manufacturing, logistics, healthcare, and research, where they contribute to increased efficiency, improved productivity, and enhanced workplace safety.

The Rising Demand for Automation in Manufacturing Industries Fuels Market Growth

The escalating demand for automation stands as a pivotal factor significantly driving the collaborative robots market growth. As industries globally recognize the need to enhance efficiency and productivity, automation emerges as a strategic solution. Collaborative robots, designed to work alongside human counterparts, address the need for seamless human-robot collaboration in diverse sectors. The requirement for increased efficiency and the quest for streamlined processes are pushing businesses to adopt cobots, which offer flexibility, ease of deployment, and cost-effectiveness.

As per the World Robotics report, the year 2022 witnessed the installation of 553,052 robots in manufacturing facilities, surpassing the previous year's record of 526,144 units. With the collaborative aspect ensuring a safer working environment, these robots are gaining prominence across industries. The symbiotic relationship between the growing demand for automation and the unique capabilities of collaborative robots positions them as a transformative force, driving substantial growth in the automation landscape.

Increased Adoption in Small and Medium-sized Enterprises (SMEs) Fuels Growth

The driving force behind the growth of the collaborative robots market lies in the escalating adoption within Small and Medium-sized Enterprises (SMEs). This trend is reshaping the automation landscape by offering SMEs a pragmatic and transformative approach to integrating robotics into their operations. Unlike conventional industrial robots that often pose challenges in terms of cost, complexity, and adaptability, cobots are specifically designed to cater to the unique needs of SMEs. Their inherent flexibility, user-friendly interfaces, and modular functionalities make them not only cost-effective but also readily adaptable to the dynamic workflow characteristic of smaller businesses.

Furthermore, the collaborative and safe features of cobots make them conducive to working alongside human counterparts, a crucial aspect in environments where close interaction between humans and robots is paramount. As SMEs increasingly recognize the advantages of cobots in enhancing efficiency, productivity, and overall competitiveness, their adoption becomes a pivotal driver of market growth.

Lack of Awareness and Skilled Workforce Hinders Market Expansion

The lack of awareness and a shortage of skilled workforce emerge as substantial constraints, restraining the growth trend of the collaborative robot market. Insufficient awareness among potential adopters about the capabilities and advantages of collaborative robots significantly hampers their widespread adoption. This lack of awareness extends across industries, impeding the market's expansion as businesses may remain uninformed about how cobots can revolutionize and optimize their operational processes.

Moreover, the shortage of a skilled workforce capable of understanding, implementing, and maintaining collaborative robot systems poses a formidable challenge. The complexity associated with cobot integration and programming demands a workforce with specialized skills in robotics and automation. The scarcity of professionals proficient in these domains inhibits the seamless deployment of collaborative robots across various industries.

Innovations in Robotics Technology Creates Market Opportunities

Continuous innovations in robotics technology are expected to be a pivotal factor in creating abundant opportunities in the collaborative robot market in the coming years. The dynamic landscape of robotics is witnessing advancements that span improved sensing capabilities, sophisticated control systems, and seamless integration of artificial intelligence. These technological breakthroughs are not only expanding the functionalities of collaborative robots but are also broadening their applications across various industries.

A notable instance illustrating this trend is ABB Robotics' recent extension of its Wizard Easy Programming software in November 2023. The software's expanded compatibility now includes collaborative robots powered by the OmniCore controller. This strategic move by ABB Robotics addresses the critical challenges posed by a shortage of skilled labor while aligning with the increasing demand for simplified and user-friendly programming solutions. Such developments exemplify how innovations in robotics technology directly tackle industry challenges and cater to manufacturers seeking accessible programming tools for their diverse robotic fleets. As robotics technology continues to progress, the collaborative robot market is positioned to benefit from more intuitive, adaptable, and efficient robotic systems.

North America Holds the Dominant Market Share in the Global Market

North America's robust manufacturing base plays a crucial role in the adoption of collaborative robots. With applications ranging from assembly lines to quality control processes, cobots find extensive use in the region's diverse industrial landscape. Moreover, the substantial investments and funding in the robotics and automation sector further accelerate the growth of collaborative robots in North America. Financial support for research, development, and deployment initiatives contributes to the continual evolution of cobot technologies, making them more sophisticated and applicable to a wide range of industries.

A noteworthy initiative in the United States contributing to this momentum is the National Robotics Initiative (NRI), which was established to foster fundamental research and development in robotics with support from the US government. Additionally, the U.S. government demonstrated its commitment to this cause by allocating a substantial sum of 14 million USD to the NRI-3.0 fund in 2021. This financial support not only underscores the importance of advancing robotics technology but also highlights the government's recognition of the potential impact and significance of collaborative robots in shaping the future landscape of various industries.

Asia Pacific is Expected to Show Steady Growth in the Global Market

The Asia Pacific region, particularly countries like China, Japan, and South Korea, is experiencing a significant manufacturing boom. The demand for cobots is driven by the need for automation to enhance production efficiency and competitiveness. According to recent reports from the International Federation of Robotics, China has firmly secured its position as the world's largest market for industrial robots, closely shadowed by Japan.

In 2022, China set a new benchmark with annual robot installations totaling 290,258 units, marking a noteworthy 5% growth compared to the preceding year. Japan, acclaimed as the global leader in robot manufacturing, commands a remarkable market share of 46% of the total global robot production. Simultaneously, the Republic of Korea's market witnessed a 1% rise, with installations reaching 31,716 units in 2022. These findings underscore the dynamic and thriving landscape of the robotics industry in the Asia Pacific region.

Furthermore, the substantial growth of the cobots market in the Asia Pacific region is significantly driven by the rapid proliferation of smart factories across the region. Smart factories, characterized by the integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence, and automation, are revolutionizing traditional manufacturing processes.

The World Economic Forum has identified the impact of Industry 4.0 by identifying 18 additional 'lighthouse' factories that have successfully transcended macroeconomic challenges through the adoption of the latest industrial IoT-related technologies. Notably, China hosts 44 percent of these new lighthouse factories (eight out of 18), demonstrating its leadership in embracing advanced manufacturing practices.

Furthermore, Southern and Southeast Asia, encompassing countries like India, Japan, Thailand, and the Philippines, account for almost 28 percent (five out of 18) of these innovative Industry 4.0 exemplars. As industries increasingly embrace the principles of Industry 4.0 and establish smart manufacturing environments, the demand for collaborative robots continues to grow, making them a significant driving force in the expanding cobots market.

Competitive Landscape

Several market players operating in the collaborative robot industry include Locus Robotics, Fanuc, Kuka AG, Yaskawa Electric Corporation, Denso Corporation, Universal Robots, Doosan Robotics Inc., Rethink Robotics GmbH, Techman Robot Inc., and Precise Automation among others. These market players are adopting strategies, such as product launches, across various regions, to maintain their dominance in the market.

For instance, in May 2023, FANUC America unveiled two additional collaborative robots with high-payload capacity during the Automate 2023 event. With this introduction, FANUC's portfolio now comprises 11 different cobot models, each versatile enough to be employed across various industrial applications such as assembly, inspection, material handling, packaging, palletizing, sanding, welding, and more.

Moreover, in September 2022, KUKA unveiled two novel cobot models, the LBR iisy 11 kg and the LBR iisy 15 kg. These two highly sensitive lightweight cobots have been designed to cater to a diverse array of tasks and applications. They come with expanded payload capacities, considerably longer reaches, and a higher IP protection class, enhancing their adaptability and performance in various industrial settings.

Collaborative Robot Market Key Segments

By Component

-

Hardware

-

Robotic Arm

-

End Effector or End of ARM Tool (EOAT)

-

Drivers

-

Controllers

-

Sensors

-

Power Supply

-

Motors

-

Other Hardware

-

-

Software

By Payload Capacity

-

Up to 5 Kg

-

Between 5 Kg and 10 Kg

-

More than 10 Kg

By Application

-

Handling

-

Assembling & Disassembling

-

Welding & Soldering

-

Dispensing

-

Processing

-

Others

By Industry Verticals

-

Automotive

-

Electronics

-

Metals & Machining

-

Plastics & Polymers

-

Food & Beverages

-

Furniture & Equipment

-

Healthcare

-

Other Industries

By Region

-

North America

-

The U.S.

-

Canada

-

Mexico

-

-

Europe

-

The UK

-

Germany

-

France

-

Italy

-

Spain

-

Denmark

-

Netherlands

-

Rest of Europe

-

-

Asia Pacific

-

China

-

Japan

-

India

-

South Korea

-

Australia

-

Taiwan

-

Vietnam

-

Rest of Asia Pacific

-

-

RoW

-

Latin America

-

Middle East

-

Africa

-

Key Players:

-

Locus Robotics

-

Fanuc

-

Kuka AG

-

Yaskawa Electric Corporation

-

Denso Corporation

-

Universal Robots

-

Doosan Robotics Inc.

-

Rethink Robotics GmbH

-

Techman Robot Inc.

-

Precise Automation

REPORT SCOPE AND SEGMENTATION:

|

Parameters |

Details |

|

Market Size in 2023 |

USD 1.77 Billion |

|

Revenue Forecast in 2030 |

USD 12.71 Billion |

|

Growth Rate |

CAGR of 32.6% from 2024 to 2030 |

|

Analysis Period |

2023–2030 |

|

Base Year Considered |

2023 |

|

Forecast Period |

2024–2030 |

|

Market Size Estimation |

Billion (USD) |

|

Growth Factors |

The rising demand for automation in manufacturing industries fuels market growth |

|

Countries Covered |

22 |

|

Companies Profiled |

10 |

|

Market Share |

Available for 10 companies |

|

Customization Scope |

Free customization (equivalent up to 80 working hours of analysts) after purchase. Addition or alteration to country, regional, and segment scope. |

|

Pricing and Purchase Options |

Avail customized purchase options to meet your exact research needs. |

Speak to Our Analyst

Speak to Our Analyst