Warehouse Robotics Market

Warehouse Robotics Market by Type (Automated Guided Vehicles (AGVs), Autonomous Mobile Robots (AMRs), Articulated Robots, and Others), by Offering (Hardware, Software, and Services), by Payload Capacity (Less than 100 KG, 101-200 KG, 201-500 KG, and Others), by Application (Palletizing and Depalletizing, Sorting and Packaging, Picking and Placing, Transportation), and by End-User (E-commerce, Automotive, Food & Beverages, and Others)– Global Opportunity Analysis and Industry Forecast 2025–2030

Industry: ICT & Media | Publish Date: 07-Mar-2025 | No of Pages: 966 | No. of Tables: 682 | No. of Figures: 627 | Format: PDF | Report Code : IC424

US Tariff Impact on Warehouse Robotics Market

Trump Tariffs Are Reshaping Global Business

Warehouse Robotics Market Overview

The global Warehouse Robotics Market size was valued at USD 10.11 billion in 2024 and is predicted to reach USD 28.32 billion by 2030 with a CAGR of 17.7% from 2025-2030. In terms of volume the market size was 479.6 thousand units in 2024 and is projected to reach 1466.6 thousand units in 2030, with a CAGR of 19.3% from 2025 to 2030.

Factors such as increased investment in Industry 4.0, rising labor costs alongside workforce shortages and industrial accidents are driving demand for industrial and warehouse robotics.

However, high initial costs and complexity in system integration challenge market growth. On the other hand, collaborative robots (cobots) are achieving success, especially among Small and Medium-sized Enterprises (SMEs) in search of automation solutions.

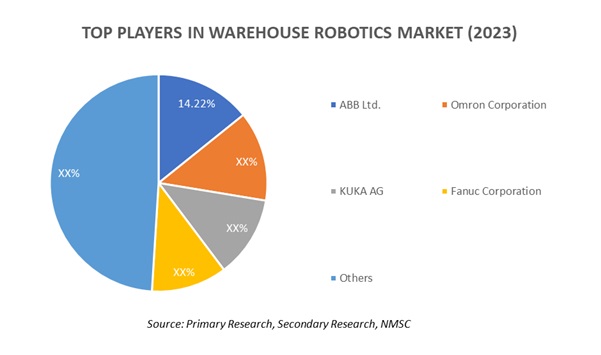

Key players such as ABB Ltd., Omron Corporation, and others are driving innovation through collaborations and product launches. Thus, the growing adoption of robotics is transforming industrial operations thereby enhancing productivity and addressing workforce challenges.

Growing Investment in Smart Factories and Industry 4.0 Initiatives is Driving the Warehouse Robotics Market Growth

The growth in global investment in Industry 4.0 is contributing to the expansion of the market as these robots are essential to achieve automation, precision, and efficiency in advanced manufacturing and smart factories.

The latest report published by World Economic Forum, 2023, investments in Industry 4.0 initiatives are steadily increasing, where digital transformation is expected to reach USD 298.2 billion in the MENA region up to 2032.

The rising investments in industry 4.0 initiatives are accelerating the adoption of industrial robots, driving significant warehouse robotics market growth by enabling smarter and more efficient manufacturing processes.

Rise in Labour Costs and Workforce Shortages Accelerates the Warehouse Robotics Market Demand

The lack of workers in various countries is compelling the need for robots to be used in warehouses, as these robots can effectively fill labour gaps and maintain productivity in industries that are facing workforce challenges.

According to Conference Board reports of 2024, the U.S. requires 4.6 million new employees every year. Germany, South Korea and China face shortages at a higher scale of 1.6 million, 2 million and 47 million respectively. Such deficiencies force the companies to deploy automation and robots for effective production requirements, thereby contributing to the market growth.

Increased Industrial Accidents Fuel the Requirement for Warehouse Robotics

With a rise in industrial accidents and diseases, the requirement for warehouse robots is increasing since they can undertake hazardous tasks much more safely thereby reducing risk to human workers and improving workplace safety.

According to reports published by International Labour Organisation, in 2023, it is estimated that around 3 million workers die every year from work-related accidents in industries.

This high mortality rate is driving the adoption of warehouse robots that reduce human involvement in hazardous tasks and improve safety in workplaces thereby driving the warehouse robotics market growth.

High Cost and Complexity Associated with the Setup of Warehouse Automation Hinder the Market Growth

High initial investment and the complexity of integrating warehouse automation into existing systems are key challenges hindering the market expansion. The difficulty in affording automation solutions, especially for SMEs, further limits the wider adoption of these solutions. Thus, these issues pose challenges for small enterprise slowing down the adoption of these robots thereby restraining the overall growth of the market.

Growing Adoption of Collaborative Robots is Expected to Create Ample Future Opportunities

Rising demand for cobots in SMEs is highly expected to drive the growth of the market since the cobots can work alongside human workers by mitigating the need for major safety measures. The cobots are also considered cost-efficient as they require minimal setting and easy programming for various purposes.

The latest report from Association for Advancing Automation states, collaborative robots is expected to experience a significant growth over the next several years by reaching USD 7.5 billion by 2027 equating roughly 29% of the overall industrial robots.

Thus, the falling prices combined with their flexibility and ease of integration is anticipated to boost the adoption of cobots that will make automation more accessible for enterprises and thus drive the market growth.

By Type, Articulated Robots Holds the Dominating Share with 31.7% in the Warehouse Robotics Market

Articulated robots dominate the type segment in the warehouse robotics market, holding the largest share with 31.7% share. Their dominance is attributed to their high flexibility, multi-axis movement, and ability to handle complex tasks such as picking, packing, and palletization.

These robots offer enhanced precision and adaptability making them ideal for various warehouse applications from high-speed sorting to heavy-duty lifting. Their seamless integration into automated systems further strengthens their leadership in the market.

By Application, Transportation Holds the Highest CAGR of 19.4%

Transportation will be the most growth-intensive segment, with a projected CAGR of 19.4% during the 2025-2030 period. This growth is primarily driven by the increasing demand for efficient logistics and the need for automation in the transportation sector.

Additionally, advancements in robotics and AI technologies are further boosting the adoption of automated systems, improving speed, accuracy, and cost-effectiveness.

Asia-Pacific Dominates the Warehouse Robotics Market Share

Asia-Pacific, that consists of countries including China, India, Japan, and more holds the highest share in the global warehouse robot market. Investment by the regional governments in subsidies and such initiatives takes a propelling effect on the adoption of industrial robots in the region, driving the growth and expansion of market automation.

As per reports published by ORCA, 2024, China’s government investments in warehouse robots to boosts the market’s growth by increasing the robot density rate to 392 robots per 10,000 workers in 2023, up from 97 in 2017.

China accounted for 52% of global new factory robot installations in 2022, maintaining its position as the largest market. Government investments, therefore, play a key role in boosting warehouse robot adoption as the market continues to experience substantial growth and technological advancement.

Moreover, the increasing number of industrial deaths in the region is pushing up the demand for the warehouse robot market, as companies are seeking automation solutions that will improve the safety of their workers and minimize fatalities.

According to reports released by National Library of Medicines, 2023, South Korea's industrial accident mortality rate is 0.58% that is considerably higher than countries including Germany at 0.16% and the U.S. in 0.36%. This high industrial accident mortality rate in countries is fueling the demand for warehouse robotics to enhance workers safety and reduce fatalities in the region.

North America is Expected to Show a Steady Growth in the Warehouse Robotics Market with a CAGR of 22.8% till 2030

These e-commerce businesses in the regions, such as Amazon, Walmart, and Shopify, are gaining rapid growth across the region at a high order fulfilment rate based on fast delivery, efficiency, and accuracy. As these warehouses grow in the platforms, they need automation solutions such as AMRs, articulated robots, and others to boost their productivity and speed in order fulfilment.

According to the report of the ecommerce tips, the retail ecommerce sales in the U.S. in 2022 were approximately around USD 1.05 trillion, that grew about to USD 1.67 trillion with a CAGR of 12.5%.

Thus, this rising ecommerce sales further emphasize the increased demand for more advanced warehouse robotics to enable companies to operate in a streamlined manner in order to address the surging demands of consumers.

Also, major companies in the country, such as Amazon, DHL, and Walmart, are spending on smart warehouse infrastructure to upscale operational efficiency and scalability. By integration warehouse robots with WMS software and internet of things (IoT), businesses are streamlining management by optimizing workflows, and improving real-time data tracking.

For instance, in October 2023, Amazon introduced new robotics solutions to enhance efficiency and safety across its fulfilment centers. This launch includes Sequoia a robotic system that speeds up inventory management by identifying and moving products quickly, reducing the time needed to process the orders.

Thus, these advancements in smart warehousing and robotics adoption are reshaping the companies by allowing quicker order fulfilment, greater productivity, and higher responsiveness.

Competitive Landscape

The warehouse robotics industry includes various market players such as ABB Ltd., Omron Corporation, KUKA AG, Fanuc Corporation, JBT Corporation, Teradyne Inc., Geekplus Technology Co., Ltd., GreyOrange, Bastian Solutions, LLC, Locus Robotics, Seegrid Corporation, Doosan Robotics Inc., Lucas Robotics, Zebra Technologies Corporation, Mitsubishi Electric Automation Inc., and others. These market players are adopting several strategies such as product launches, partnerships, and business expansions across various regions to maintain their dominance in the market.

These market players are adopting several strategies such as product launches and partnerships across various regions to maintain their dominance in the market.

|

DATE |

COMPANY |

RECENT DEVELOPMENTS |

|

January 2025 |

Teradyne Inc. |

Teradyne Robotics and Analog Devices partnered on the development of artificial intelligence-driven collaborative automation. The new collaboration incorporates Analog Devices' technology into Teradyne's robotics, further improving performance, safety, and efficiency in many industries, including semiconductor manufacturing. |

|

November 2024 |

FANUC Corporation |

FANUC Corporation announced the introduction of the new five-axis model M-950iA. It is a serial-link articulated robot that operates in confined and restricted work areas. It handles up to 500 kg in payloads. Accordingly, it carries both high-payload capacity along with wide-range motion. |

|

October 2024 |

Mitsubishi Electric Automation Inc. |

Mitsubishi Electric Automation Inc. introduced the MELFA RV-12CRL: a 4.9-foot reach factory robot arm with a maximum lifting capacity of 26 pounds for applications in machine tending, case packing, and pick-and-place operations. |

|

June 2024 |

ABB Ltd. |

ABB Robotics added the IRB 7710 and IRB 7720 to its warehouse robot market portfolio, offering a 25% reduction in cycle times and a 30% decrease in energy consumption. |

|

May 2024 |

Omron Corporation |

OMRON and Neura Robotics collaborated to improve manufacturing efficiency through AI-driven cognitive automation. The OMRON intelligent Cognitive Robot (iCR) series, based on the Neura Robotics MAIRA line, integrates sensors, AI technologies, optional 3D vision, and safety in industrial settings. |

|

January 2024 |

Kuka AG |

KUKA launched KR FORTEC industrial robot, designed for dynamic manipulation tasks featuring high dynamic performance and hence short cycle time at low energy consumption in compact design. The design, with the lines flowing in from all directions, makes this robot suitable for multiple tasks, for example, in automobile production. |

Warehouse Robotics Market Key Segments

By Type

-

Automated Guided Vehicles (AGVs)

-

Laser Guidance

-

Magnetic Guidance

-

Optical Tape Guidance

-

Vision Guidance

-

Others

-

-

Autonomous Mobile Robots (AMRs)

-

Tow Vehicle

-

Tug Vehicle

-

Unit Load Vehicle

-

Pallet Truck

-

Forklift Vehicle

-

Other Type

-

-

Articulated Robots

-

Collaborative Robots

-

Scara Robots and Cylindrical Robots

-

Others

By Offering

-

Hardware

-

Software

-

Warehouse Management System (WMS)

-

Warehouse Execution System (WES)

-

Warehouse Control System (WCS)

-

-

Services

By Payload Capacity

-

Less than 100 KG

-

101-200 KG

-

201-500 KG

-

501-1000 KG

-

1001-2000 KG

-

2001-5000 KG

-

More than 5000 KG

By Application

-

Palletizing and depalletizing

-

Sorting and Packaging

-

Picking and Placing

-

Transportation

By End-User

-

E-commerce

-

Automotive

-

Food & Beverages

-

Pharmaceutical

-

Chemical and Materials

-

Semiconductor and Electronics

-

Others

By Geography

-

North America

-

U.S

-

Canada

-

Mexico

-

-

Europe

-

UK

-

Germany

-

France

-

Italy

-

Spain

-

Denmark

-

Netherlands

-

Finland

-

Sweden

-

Norway

-

Russia

-

Rest of Europe

-

-

Asia-Pacific

-

China

-

Japan

-

India

-

Australia

-

South Korea

-

Taiwan

-

Indonesia

-

Singapore

-

Thailand

-

Rest of Asia-Pacific

-

-

RoW

-

Latin America

-

Middle East

-

Africa

-

Key Players

-

ABB Ltd.

-

Omron Corporation

-

KUKA AG

-

Fanuc Corporation

-

JBT Corporation

-

Teradyne Inc.

-

Geekplus Technology Co., Ltd.

-

GreyOrange

-

Bastian Solutions, LLC

-

Locus Robotics

-

Seegrid Corporation

-

Doosan Robotics Inc.

-

Lucas Robotics

-

Zebra Technologies Corporation

-

Mitsubishi Electric Automation Inc.

REPORT SCOPE AND SEGMENTATION:

|

Parameters |

Details |

|

Market Size in 2024 (Value) |

USD 10.11 Billion |

|

Revenue Forecast in 2030 |

USD 28.32 Billion |

|

Growth Rate (Value) |

CAGR of 17.7% from 2025 to 2030 |

|

Analysis Period |

2024–2030 |

|

Market Volume in 2024 |

USD 479.6 Thousand Unit |

|

Volume Forecast in 2030 |

USD 1466.6 Thousand Unit |

|

Growth Rate (Volume) |

CAGR of 19.3% from 2025 to 2030 |

|

Base Year Considered |

2024 |

|

Forecast Period |

2025–2030 |

|

Market Size Estimation |

Billion (USD) |

|

Growth Factors |

|

|

Countries Covered |

28 |

|

Companies Profiled |

15 |

|

Market Share |

Available for 10 companies |

|

Customization Scope |

Free customization (equivalent up to 80 analysts working hours) after purchase. Addition or alteration to country, regional & segment scope. |

|

Pricing and Purchase Options |

Avail customized purchase options to meet your exact research needs. |

1 INTRODUCTION

1.1 REPORT DESCRIPTION

1.2 RESEARCH METHODOLOGY

1.2.1 SECONDARY RESEARCH

1.2.2 DATA ANALYSIS FRAMEWORK

1.2.3 MARKET SIZE ESTIMATION

1.2.4 FORECASTING

1.2.5 PRIMARY RESEARCH AND DATA VALIDATION

2 WAREHOUSE ROBOTICS MARKET – EXECUTIVE SUMMARY

2.1. MARKET SNAPSHOT, 2024 - 2030, MILLION USD

3 PORTER’S FIVE FORCE MODEL ANALYSIS

3.1 BARGAINING POWER OF SUPPLIERS

3.2 BARGAINING POWER OF BUYERS

3.3 DEGREE OF COMPETITION

3.4 THREAT OF SUBSTITUTE

3.5 THREAT OF NEW ENTRANTS

4 MARKET SHARE ANALYSIS

4.1 MARKET SHARE ANALYSIS OF TOP PROVIDERS, 2024

5 MARKET DYNAMICS

5.1 GROWTH DRIVERS

5.1.1 DRIVER 1

5.1.2 DRIVER 2

5.1.3 DRIVER 3

5.1.4 DRIVER 4

5.2 CHALLENGES

5.2.1 CHALLENGE 1

5.2.2 CHALLENGE 2

5.2.3 CHALLENGE 3

5.2.4 CHALLENGE 4

5.3 OPPORTUNITIES

5.3.1 OPPORTUNITY 1

5.3.2 OPPORTUNITY 2

6 GLOBAL WAREHOUSE ROBOTICS MARKET BY TYPES

6.1 OVERVIEW

6.2 AUTOMATED GUIDED VEHICLES (AGVS)

6.2.1 AUTOMATED GUIDED VEHICLES (AGVS) MARKET, BY REGION

6.2.1.1 NORTH AMERICA AUTOMATED GUIDED VEHICLES (AGVS) MARKET, BY COUNTRY

6.2.1.2 EUROPE AUTOMATED GUIDED VEHICLES (AGVS) MARKET, BY COUNTRY

6.2.1.3 ASIA-PACIFIC AUTOMATED GUIDED VEHICLES (AGVS) MARKET, BY COUNTRY

6.2.1.4 REST OF THE WORLD AUTOMATED GUIDED VEHICLES (AGVS) MARKET, BY COUNTRY

6.3 AUTONOMOUS MOBILE ROBOTS (AMRS)

6.3.1 AUTONOMOUS MOBILE ROBOTS (AMRS) MARKET, BY REGION

6.3.1.1 NORTH AMERICA AUTONOMOUS MOBILE ROBOTS (AMRS) MARKET, BY COUNTRY

6.3.1.2 EUROPE AUTONOMOUS MOBILE ROBOTS (AMRS) MARKET, BY COUNTRY

6.3.1.3 ASIA-PACIFIC AUTONOMOUS MOBILE ROBOTS (AMRS) MARKET, BY COUNTRY

6.3.1.4 REST OF THE WORLD AUTONOMOUS MOBILE ROBOTS (AMRS) MARKET, BY COUNTRY

6.4 ARTICULATED ROBOTS

6.4.1 ARTICULATED ROBOTS MARKET, BY REGION

6.4.1.1 NORTH AMERICA ARTICULATED ROBOTS MARKET, BY COUNTRY

6.4.1.2 EUROPE ARTICULATED ROBOTS MARKET, BY COUNTRY

6.4.1.3 ASIA-PACIFIC ARTICULATED ROBOTS MARKET, BY COUNTRY

6.4.1.4 REST OF THE WORLD ARTICULATED ROBOTS MARKET, BY COUNTRY

6.5 COLLABORATIVE ROBOTS (COBOT)

6.5.1 COLLABORATIVE ROBOTS (COBOT) MARKET, BY REGION

6.5.1.1 NORTH AMERICA COLLABORATIVE ROBOTS (COBOT) MARKET, BY COUNTRY

6.5.1.2 EUROPE COLLABORATIVE ROBOTS (COBOT) MARKET, BY COUNTRY

6.5.1.3 ASIA-PACIFIC COLLABORATIVE ROBOTS (COBOT) MARKET, BY COUNTRY

6.5.1.4 REST OF THE WORLD COLLABORATIVE ROBOTS (COBOT) MARKET, BY COUNTRY

6.6 SCARA ROBOTS AND CYLINDRICAL ROBOT

6.6.1 SCARA ROBOTS AND CYLINDRICAL ROBOT MARKET, BY REGION

6.6.1.1 NORTH AMERICA SCARA ROBOTS AND CYLINDRICAL ROBOT MARKET, BY COUNTRY

6.6.1.2 EUROPE SCARA ROBOTS AND CYLINDRICAL ROBOT MARKET, BY COUNTRY

6.6.1.3 ASIA-PACIFIC SCARA ROBOTS AND CYLINDRICAL ROBOT MARKET, BY COUNTRY

6.6.1.4 REST OF THE WORLD SCARA ROBOTS AND CYLINDRICAL ROBOT MARKET, BY COUNTRY

6.7 OTHERS

6.7.1 OTHERS MARKET, BY REGION

6.7.1.1 NORTH AMERICA OTHERS MARKET, BY COUNTRY

6.7.1.2 EUROPE OTHERS MARKET, BY COUNTRY

6.7.1.3 ASIA-PACIFIC OTHERS MARKET, BY COUNTRY

6.7.1.4 REST OF THE WORLD OTHERS MARKET, BY COUNTRY

7 GLOBAL WAREHOUSE ROBOTICS MARKET BY OFFERINGS

7.1 OVERVIEW

7.2 HARDWARE

7.2.1 HARDWARE MARKET, BY REGION

7.2.1.1 NORTH AMERICA HARDWARE MARKET, BY COUNTRY

7.2.1.2 EUROPE HARDWARE MARKET, BY COUNTRY

7.2.1.3 ASIA-PACIFIC HARDWARE MARKET, BY COUNTRY

7.2.1.4 REST OF THE WORLD HARDWARE MARKET, BY COUNTRY

7.3 SOFTWARE

7.3.1 GLOBAL SOFTWARE MARKET, BY OFFERINGS

7.3.1.1 WAREHOUSE MANAGEMENT SYSTEM (WMS) MARKET, BY REGION

7.3.1.1.1 NORTH AMERICA WAREHOUSE MANAGEMENT SYSTEM (WMS) MARKET, BY COUNTRY

7.3.1.1.2 EUROPE WAREHOUSE MANAGEMENT SYSTEM (WMS) MARKET, BY COUNTRY

7.3.1.1.3 ASIA-PACIFIC WAREHOUSE MANAGEMENT SYSTEM (WMS) MARKET, BY COUNTRY

7.3.1.1.4 REST OF THE WORLD WAREHOUSE MANAGEMENT SYSTEM (WMS) MARKET, BY COUNTRY

7.3.1.2 WAREHOUSE EXECUTION SYSTEM (WES) MARKET, BY REGION

7.3.1.2.1 NORTH AMERICA WAREHOUSE EXECUTION SYSTEM (WES) MARKET, BY COUNTRY

7.3.1.2.2 EUROPE WAREHOUSE EXECUTION SYSTEM (WES) MARKET, BY COUNTRY

7.3.1.2.3 ASIA-PACIFIC WAREHOUSE EXECUTION SYSTEM (WES) MARKET, BY COUNTRY

7.3.1.2.4 REST OF THE WORLD WAREHOUSE EXECUTION SYSTEM (WES) MARKET, BY COUNTRY

7.3.1.3 WAREHOUSE CONTROL SYSTEM (WCS) MARKET, BY REGION

7.3.1.3.1 NORTH AMERICA WAREHOUSE CONTROL SYSTEM (WCS) MARKET, BY COUNTRY

7.3.1.3.2 EUROPE WAREHOUSE CONTROL SYSTEM (WCS) MARKET, BY COUNTRY

7.3.1.3.3 ASIA-PACIFIC WAREHOUSE CONTROL SYSTEM (WCS) MARKET, BY COUNTRY

7.3.1.3.4 REST OF THE WORLD WAREHOUSE CONTROL SYSTEM (WCS) MARKET, BY COUNTRY

7.3.2 SOFTWARE MARKET, BY REGION

7.3.2.1 NORTH AMERICA SOFTWARE MARKET, BY COUNTRY

7.3.2.2 EUROPE SOFTWARE MARKET, BY COUNTRY

7.3.2.3 ASIA-PACIFIC SOFTWARE MARKET, BY COUNTRY

7.3.2.4 REST OF THE WORLD SOFTWARE MARKET, BY COUNTRY

7.4 SERVICES

7.4.1 SERVICES MARKET, BY REGION

7.4.1.1 NORTH AMERICA SERVICES MARKET, BY COUNTRY

7.4.1.2 EUROPE SERVICES MARKET, BY COUNTRY

7.4.1.3 ASIA-PACIFIC SERVICES MARKET, BY COUNTRY

7.4.1.4 REST OF THE WORLD SERVICES MARKET, BY COUNTRY

8 GLOBAL WAREHOUSE ROBOTICS MARKET BY PAYLOAD CAPACITY

8.1 OVERVIEW

8.2 LESS 100 KG

8.2.1 LESS 100 KG MARKET, BY REGION

8.2.1.1 NORTH AMERICA LESS 100 KG MARKET, BY COUNTRY

8.2.1.2 EUROPE LESS 100 KG MARKET, BY COUNTRY

8.2.1.3 ASIA-PACIFIC LESS 100 KG MARKET, BY COUNTRY

8.2.1.4 REST OF THE WORLD LESS 100 KG MARKET, BY COUNTRY

8.3 101-200 KG

8.3.1 101-200 KG MARKET, BY REGION

8.3.1.1 NORTH AMERICA 101-200 KG MARKET, BY COUNTRY

8.3.1.2 EUROPE 101-200 KG MARKET, BY COUNTRY

8.3.1.3 ASIA-PACIFIC 101-200 KG MARKET, BY COUNTRY

8.3.1.4 REST OF THE WORLD 101-200 KG MARKET, BY COUNTRY

8.4 201-500 KG

8.4.1 201-500 KG MARKET, BY REGION

8.4.1.1 NORTH AMERICA 201-500 KG MARKET, BY COUNTRY

8.4.1.2 EUROPE 201-500 KG MARKET, BY COUNTRY

8.4.1.3 ASIA-PACIFIC 201-500 KG MARKET, BY COUNTRY

8.4.1.4 REST OF THE WORLD 201-500 KG MARKET, BY COUNTRY

8.5 501-1000 KG

8.5.1 501-1000 KG MARKET, BY REGION

8.5.1.1 NORTH AMERICA 501-1000 KG MARKET, BY COUNTRY

8.5.1.2 EUROPE 501-1000 KG MARKET, BY COUNTRY

8.5.1.3 ASIA-PACIFIC 501-1000 KG MARKET, BY COUNTRY

8.5.1.4 REST OF THE WORLD 501-1000 KG MARKET, BY COUNTRY

8.6 1001-2000 KG

8.6.1 1001-2000 KG MARKET, BY REGION

8.6.1.1 NORTH AMERICA 1001-2000 KG MARKET, BY COUNTRY

8.6.1.2 EUROPE 1001-2000 KG MARKET, BY COUNTRY

8.6.1.3 ASIA-PACIFIC 1001-2000 KG MARKET, BY COUNTRY

8.6.1.4 REST OF THE WORLD 1001-2000 KG MARKET, BY COUNTRY

8.7 2001-5000KG

8.7.1 2001-5000KG MARKET, BY REGION

8.7.1.1 NORTH AMERICA 2001-5000KG MARKET, BY COUNTRY

8.7.1.2 EUROPE 2001-5000KG MARKET, BY COUNTRY

8.7.1.3 ASIA-PACIFIC 2001-5000KG MARKET, BY COUNTRY

8.7.1.4 REST OF THE WORLD 2001-5000KG MARKET, BY COUNTRY

9 GLOBAL WAREHOUSE ROBOTICS MARKET BY APPLICATION

9.1 OVERVIEW

9.2 PALLETIZING AND DEPALLETIZING

9.2.1 PALLETIZING AND DEPALLETIZING MARKET, BY REGION

9.2.1.1 NORTH AMERICA PALLETIZING AND DEPALLETIZING MARKET, BY COUNTRY

9.2.1.2 EUROPE PALLETIZING AND DEPALLETIZING MARKET, BY COUNTRY

9.2.1.3 ASIA-PACIFIC PALLETIZING AND DEPALLETIZING MARKET, BY COUNTRY

9.2.1.4 REST OF THE WORLD PALLETIZING AND DEPALLETIZING MARKET, BY COUNTRY

9.3 SORTING AND PACKAGING

9.3.1 SORTING AND PACKAGING MARKET, BY REGION

9.3.1.1 NORTH AMERICA SORTING AND PACKAGING MARKET, BY COUNTRY

9.3.1.2 EUROPE SORTING AND PACKAGING MARKET, BY COUNTRY

9.3.1.3 ASIA-PACIFIC SORTING AND PACKAGING MARKET, BY COUNTRY

9.3.1.4 REST OF THE WORLD SORTING AND PACKAGING MARKET, BY COUNTRY

9.4 PICKING AND PLACING

9.4.1 PICKING AND PLACING MARKET, BY REGION

9.4.1.1 NORTH AMERICA PICKING AND PLACING MARKET, BY COUNTRY

9.4.1.2 EUROPE PICKING AND PLACING MARKET, BY COUNTRY

9.4.1.3 ASIA-PACIFIC PICKING AND PLACING MARKET, BY COUNTRY

9.4.1.4 REST OF THE WORLD PICKING AND PLACING MARKET, BY COUNTRY

9.5 TRANSPORTATION

9.5.1 TRANSPORTATION MARKET, BY REGION

9.5.1.1 NORTH AMERICA TRANSPORTATION MARKET, BY COUNTRY

9.5.1.2 EUROPE TRANSPORTATION MARKET, BY COUNTRY

9.5.1.3 ASIA-PACIFIC TRANSPORTATION MARKET, BY COUNTRY

9.5.1.4 REST OF THE WORLD TRANSPORTATION MARKET, BY COUNTRY

10 GLOBAL WAREHOUSE ROBOTICS MARKET BY END USER

10.1 OVERVIEW

10.2 E-COMMERCE

10.2.1 E-COMMERCE MARKET, BY REGION

10.2.1.1 NORTH AMERICA E-COMMERCE MARKET, BY COUNTRY

10.2.1.2 EUROPE E-COMMERCE MARKET, BY COUNTRY

10.2.1.3 ASIA-PACIFIC E-COMMERCE MARKET, BY COUNTRY

10.2.1.4 REST OF THE WORLD E-COMMERCE MARKET, BY COUNTRY

10.3 AUTOMOTIVE

10.3.1 AUTOMOTIVE MARKET, BY REGION

10.3.1.1 NORTH AMERICA AUTOMOTIVE MARKET, BY COUNTRY

10.3.1.2 EUROPE AUTOMOTIVE MARKET, BY COUNTRY

10.3.1.3 ASIA-PACIFIC AUTOMOTIVE MARKET, BY COUNTRY

10.3.1.4 REST OF THE WORLD AUTOMOTIVE MARKET, BY COUNTRY

10.4 FOOD AND BEVERAGES

10.4.1 FOOD AND BEVERAGES MARKET, BY REGION

10.4.1.1 NORTH AMERICA FOOD AND BEVERAGES MARKET, BY COUNTRY

10.4.1.2 EUROPE FOOD AND BEVERAGES MARKET, BY COUNTRY

10.4.1.3 ASIA-PACIFIC FOOD AND BEVERAGES MARKET, BY COUNTRY

10.4.1.4 REST OF THE WORLD FOOD AND BEVERAGES MARKET, BY COUNTRY

10.5 PHARMACEUTICAL

10.5.1 PHARMACEUTICAL MARKET, BY REGION

10.5.1.1 NORTH AMERICA PHARMACEUTICAL MARKET, BY COUNTRY

10.5.1.2 EUROPE PHARMACEUTICAL MARKET, BY COUNTRY

10.5.1.3 ASIA-PACIFIC PHARMACEUTICAL MARKET, BY COUNTRY

10.5.1.4 REST OF THE WORLD PHARMACEUTICAL MARKET, BY COUNTRY

10.6 CHEMICAL AND MATERIALS

10.6.1 CHEMICAL AND MATERIALS MARKET, BY REGION

10.6.1.1 NORTH AMERICA CHEMICAL AND MATERIALS MARKET, BY COUNTRY

10.6.1.2 EUROPE CHEMICAL AND MATERIALS MARKET, BY COUNTRY

10.6.1.3 ASIA-PACIFIC CHEMICAL AND MATERIALS MARKET, BY COUNTRY

10.6.1.4 REST OF THE WORLD CHEMICAL AND MATERIALS MARKET, BY COUNTRY

10.7 SEMICONDUCTOR AND ELECTRONICS

10.7.1 SEMICONDUCTOR AND ELECTRONICS MARKET, BY REGION

10.7.1.1 NORTH AMERICA SEMICONDUCTOR AND ELECTRONICS MARKET, BY COUNTRY

10.7.1.2 EUROPE SEMICONDUCTOR AND ELECTRONICS MARKET, BY COUNTRY

10.7.1.3 ASIA-PACIFIC SEMICONDUCTOR AND ELECTRONICS MARKET, BY COUNTRY

10.7.1.4 REST OF THE WORLD SEMICONDUCTOR AND ELECTRONICS MARKET, BY COUNTRY

10.8 OTHERS

10.8.1 OTHERS MARKET, BY REGION

10.8.1.1 NORTH AMERICA OTHERS MARKET, BY COUNTRY

10.8.1.2 EUROPE OTHERS MARKET, BY COUNTRY

10.8.1.3 ASIA-PACIFIC OTHERS MARKET, BY COUNTRY

10.8.1.4 REST OF THE WORLD OTHERS MARKET, BY COUNTRY

11 GLOBAL WAREHOUSE ROBOTICS MARKET, BY REGION

11.1 OVERVIEW

11.2 NORTH AMERICA

11.2.1 NORTH AMERICA WAREHOUSE ROBOTICS MARKET, BY TYPES

11.2.2 NORTH AMERICA WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.2.2.1 NORTH AMERICA SOFTWARE MARKET, BY OFFERINGS

11.2.3 NORTH AMERICA WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.2.4 NORTH AMERICA WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.2.5 NORTH AMERICA WAREHOUSE ROBOTICS MARKET, BY END USER

11.2.6 NORTH AMERICA WAREHOUSE ROBOTICS MARKET, BY COUNTRY

11.2.6.1 UNITED STATES

11.2.6.1.1 UNITED STATES WAREHOUSE ROBOTICS MARKET, BY TYPES

11.2.6.1.2 UNITED STATES WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.2.6.1.2.1 UNITED STATES SOFTWARE MARKET, BY OFFERINGS

11.2.6.1.3 UNITED STATES WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.2.6.1.4 UNITED STATES WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.2.6.1.5 UNITED STATES WAREHOUSE ROBOTICS MARKET, BY END USER

11.2.6.2 CANADA

11.2.6.2.1 CANADA WAREHOUSE ROBOTICS MARKET, BY TYPES

11.2.6.2.2 CANADA WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.2.6.2.2.1 CANADA SOFTWARE MARKET, BY OFFERINGS

11.2.6.2.3 CANADA WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.2.6.2.4 CANADA WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.2.6.2.5 CANADA WAREHOUSE ROBOTICS MARKET, BY END USER

11.2.6.3 MEXICO

11.2.6.3.1 MEXICO WAREHOUSE ROBOTICS MARKET, BY TYPES

11.2.6.3.2 MEXICO WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.2.6.3.2.1 MEXICO SOFTWARE MARKET, BY OFFERINGS

11.2.6.3.3 MEXICO WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.2.6.3.4 MEXICO WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.2.6.3.5 MEXICO WAREHOUSE ROBOTICS MARKET, BY END USER

11.3 EUROPE

11.3.1 EUROPE WAREHOUSE ROBOTICS MARKET, BY TYPES

11.3.2 EUROPE WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.3.2.1 EUROPE SOFTWARE MARKET, BY OFFERINGS

11.3.3 EUROPE WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.3.4 EUROPE WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.3.5 EUROPE WAREHOUSE ROBOTICS MARKET, BY END USER

11.3.6 EUROPE WAREHOUSE ROBOTICS MARKET, BY COUNTRY

11.3.6.1 GERMANY

11.3.6.1.1 GERMANY WAREHOUSE ROBOTICS MARKET, BY TYPES

11.3.6.1.2 GERMANY WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.3.6.1.2.1 GERMANY SOFTWARE MARKET, BY OFFERINGS

11.3.6.1.3 GERMANY WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.3.6.1.4 GERMANY WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.3.6.1.5 GERMANY WAREHOUSE ROBOTICS MARKET, BY END USER

11.3.6.2 FRANCE

11.3.6.2.1 FRANCE WAREHOUSE ROBOTICS MARKET, BY TYPES

11.3.6.2.2 FRANCE WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.3.6.2.2.1 FRANCE SOFTWARE MARKET, BY OFFERINGS

11.3.6.2.3 FRANCE WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.3.6.2.4 FRANCE WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.3.6.2.5 FRANCE WAREHOUSE ROBOTICS MARKET, BY END USER

11.3.6.3 ITALY

11.3.6.3.1 ITALY WAREHOUSE ROBOTICS MARKET, BY TYPES

11.3.6.3.2 ITALY WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.3.6.3.2.1 ITALY SOFTWARE MARKET, BY OFFERINGS

11.3.6.3.3 ITALY WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.3.6.3.4 ITALY WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.3.6.3.5 ITALY WAREHOUSE ROBOTICS MARKET, BY END USER

11.3.6.4 SPAIN

11.3.6.4.1 SPAIN WAREHOUSE ROBOTICS MARKET, BY TYPES

11.3.6.4.2 SPAIN WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.3.6.4.2.1 SPAIN SOFTWARE MARKET, BY OFFERINGS

11.3.6.4.3 SPAIN WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.3.6.4.4 SPAIN WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.3.6.4.5 SPAIN WAREHOUSE ROBOTICS MARKET, BY END USER

11.3.6.5 UNITED KINGDOM

11.3.6.5.1 UNITED KINGDOM WAREHOUSE ROBOTICS MARKET, BY TYPES

11.3.6.5.2 UNITED KINGDOM WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.3.6.5.2.1 UNITED KINGDOM SOFTWARE MARKET, BY OFFERINGS

11.3.6.5.3 UNITED KINGDOM WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.3.6.5.4 UNITED KINGDOM WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.3.6.5.5 UNITED KINGDOM WAREHOUSE ROBOTICS MARKET, BY END USER

11.3.6.6 RUSSIA

11.3.6.6.1 RUSSIA WAREHOUSE ROBOTICS MARKET, BY TYPES

11.3.6.6.2 RUSSIA WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.3.6.6.2.1 RUSSIA SOFTWARE MARKET, BY OFFERINGS

11.3.6.6.3 RUSSIA WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.3.6.6.4 RUSSIA WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.3.6.6.5 RUSSIA WAREHOUSE ROBOTICS MARKET, BY END USER

11.3.6.7 SWEDEN

11.3.6.7.1 SWEDEN WAREHOUSE ROBOTICS MARKET, BY TYPES

11.3.6.7.2 SWEDEN WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.3.6.7.2.1 SWEDEN SOFTWARE MARKET, BY OFFERINGS

11.3.6.7.3 SWEDEN WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.3.6.7.4 SWEDEN WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.3.6.7.5 SWEDEN WAREHOUSE ROBOTICS MARKET, BY END USER

11.3.6.8 NORWAY

11.3.6.8.1 NORWAY WAREHOUSE ROBOTICS MARKET, BY TYPES

11.3.6.8.2 NORWAY WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.3.6.8.2.1 NORWAY SOFTWARE MARKET, BY OFFERINGS

11.3.6.8.3 NORWAY WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.3.6.8.4 NORWAY WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.3.6.8.5 NORWAY WAREHOUSE ROBOTICS MARKET, BY END USER

11.3.6.9 DENMARK

11.3.6.9.1 DENMARK WAREHOUSE ROBOTICS MARKET, BY TYPES

11.3.6.9.2 DENMARK WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.3.6.9.2.1 DENMARK SOFTWARE MARKET, BY OFFERINGS

11.3.6.9.3 DENMARK WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.3.6.9.4 DENMARK WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.3.6.9.5 DENMARK WAREHOUSE ROBOTICS MARKET, BY END USER

11.3.6.10 NETHERLANDS

11.3.6.10.1 NETHERLANDS WAREHOUSE ROBOTICS MARKET, BY TYPES

11.3.6.10.2 NETHERLANDS WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.3.6.10.2.1 NETHERLANDS SOFTWARE MARKET, BY OFFERINGS

11.3.6.10.3 NETHERLANDS WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.3.6.10.4 NETHERLANDS WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.3.6.10.5 NETHERLANDS WAREHOUSE ROBOTICS MARKET, BY END USER

11.3.6.11 FINLAND

11.3.6.11.1 FINLAND WAREHOUSE ROBOTICS MARKET, BY TYPES

11.3.6.11.2 FINLAND WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.3.6.11.2.1 FINLAND SOFTWARE MARKET, BY OFFERINGS

11.3.6.11.3 FINLAND WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.3.6.11.4 FINLAND WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.3.6.11.5 FINLAND WAREHOUSE ROBOTICS MARKET, BY END USER

11.3.6.12 REST OF EUROPE

11.3.6.12.1 REST OF EUROPE WAREHOUSE ROBOTICS MARKET, BY TYPES

11.3.6.12.2 REST OF EUROPE WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.3.6.12.2.1 REST OF EUROPE SOFTWARE MARKET, BY OFFERINGS

11.3.6.12.3 REST OF EUROPE WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.3.6.12.4 REST OF EUROPE WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.3.6.12.5 REST OF EUROPE WAREHOUSE ROBOTICS MARKET, BY END USER

11.4 ASIA-PACIFIC

11.4.1 ASIA-PACIFIC WAREHOUSE ROBOTICS MARKET, BY TYPES

11.4.2 ASIA-PACIFIC WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.4.2.1 ASIA-PACIFIC SOFTWARE MARKET, BY OFFERINGS

11.4.3 ASIA-PACIFIC WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.4.4 ASIA-PACIFIC WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.4.5 ASIA-PACIFIC WAREHOUSE ROBOTICS MARKET, BY END USER

11.4.6 ASIA-PACIFIC WAREHOUSE ROBOTICS MARKET, BY COUNTRY

11.4.6.1 AUSTRALIA

11.4.6.1.1 AUSTRALIA WAREHOUSE ROBOTICS MARKET, BY TYPES

11.4.6.1.2 AUSTRALIA WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.4.6.1.2.1 AUSTRALIA SOFTWARE MARKET, BY OFFERINGS

11.4.6.1.3 AUSTRALIA WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.4.6.1.4 AUSTRALIA WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.4.6.1.5 AUSTRALIA WAREHOUSE ROBOTICS MARKET, BY END USER

11.4.6.2 CHINA

11.4.6.2.1 CHINA WAREHOUSE ROBOTICS MARKET, BY TYPES

11.4.6.2.2 CHINA WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.4.6.2.2.1 CHINA SOFTWARE MARKET, BY OFFERINGS

11.4.6.2.3 CHINA WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.4.6.2.4 CHINA WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.4.6.2.5 CHINA WAREHOUSE ROBOTICS MARKET, BY END USER

11.4.6.3 INDIA

11.4.6.3.1 INDIA WAREHOUSE ROBOTICS MARKET, BY TYPES

11.4.6.3.2 INDIA WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.4.6.3.2.1 INDIA SOFTWARE MARKET, BY OFFERINGS

11.4.6.3.3 INDIA WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.4.6.3.4 INDIA WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.4.6.3.5 INDIA WAREHOUSE ROBOTICS MARKET, BY END USER

11.4.6.4 JAPAN

11.4.6.4.1 JAPAN WAREHOUSE ROBOTICS MARKET, BY TYPES

11.4.6.4.2 JAPAN WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.4.6.4.2.1 JAPAN SOFTWARE MARKET, BY OFFERINGS

11.4.6.4.3 JAPAN WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.4.6.4.4 JAPAN WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.4.6.4.5 JAPAN WAREHOUSE ROBOTICS MARKET, BY END USER

11.4.6.5 SOUTH KOREA

11.4.6.5.1 SOUTH KOREA WAREHOUSE ROBOTICS MARKET, BY TYPES

11.4.6.5.2 SOUTH KOREA WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.4.6.5.2.1 SOUTH KOREA SOFTWARE MARKET, BY OFFERINGS

11.4.6.5.3 SOUTH KOREA WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.4.6.5.4 SOUTH KOREA WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.4.6.5.5 SOUTH KOREA WAREHOUSE ROBOTICS MARKET, BY END USER

11.4.6.6 INDONESIA

11.4.6.6.1 INDONESIA WAREHOUSE ROBOTICS MARKET, BY TYPES

11.4.6.6.2 INDONESIA WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.4.6.6.2.1 INDONESIA SOFTWARE MARKET, BY OFFERINGS

11.4.6.6.3 INDONESIA WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.4.6.6.4 INDONESIA WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.4.6.6.5 INDONESIA WAREHOUSE ROBOTICS MARKET, BY END USER

11.4.6.7 SINGAPORE

11.4.6.7.1 SINGAPORE WAREHOUSE ROBOTICS MARKET, BY TYPES

11.4.6.7.2 SINGAPORE WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.4.6.7.2.1 SINGAPORE SOFTWARE MARKET, BY OFFERINGS

11.4.6.7.3 SINGAPORE WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.4.6.7.4 SINGAPORE WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.4.6.7.5 SINGAPORE WAREHOUSE ROBOTICS MARKET, BY END USER

11.4.6.8 TAIWAN

11.4.6.8.1 TAIWAN WAREHOUSE ROBOTICS MARKET, BY TYPES

11.4.6.8.2 TAIWAN WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.4.6.8.2.1 TAIWAN SOFTWARE MARKET, BY OFFERINGS

11.4.6.8.3 TAIWAN WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.4.6.8.4 TAIWAN WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.4.6.8.5 TAIWAN WAREHOUSE ROBOTICS MARKET, BY END USER

11.4.6.9 THAILAND

11.4.6.9.1 THAILAND WAREHOUSE ROBOTICS MARKET, BY TYPES

11.4.6.9.2 THAILAND WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.4.6.9.2.1 THAILAND SOFTWARE MARKET, BY OFFERINGS

11.4.6.9.3 THAILAND WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.4.6.9.4 THAILAND WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.4.6.9.5 THAILAND WAREHOUSE ROBOTICS MARKET, BY END USER

11.4.6.10 REST OF ASIA-PACIFIC

11.4.6.10.1 REST OF ASIA-PACIFIC WAREHOUSE ROBOTICS MARKET, BY TYPES

11.4.6.10.2 REST OF ASIA-PACIFIC WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.4.6.10.2.1 REST OF ASIA-PACIFIC SOFTWARE MARKET, BY OFFERINGS

11.4.6.10.3 REST OF ASIA-PACIFIC WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.4.6.10.4 REST OF ASIA-PACIFIC WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.4.6.10.5 REST OF ASIA-PACIFIC WAREHOUSE ROBOTICS MARKET, BY END USER

11.5 REST OF THE WORLD

11.5.1 REST OF THE WORLD WAREHOUSE ROBOTICS MARKET, BY TYPES

11.5.2 REST OF THE WORLD WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.5.2.1 REST OF THE WORLD SOFTWARE MARKET, BY OFFERINGS

11.5.3 REST OF THE WORLD WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.5.4 REST OF THE WORLD WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.5.5 REST OF THE WORLD WAREHOUSE ROBOTICS MARKET, BY END USER

11.5.6 REST OF THE WORLD WAREHOUSE ROBOTICS MARKET, BY COUNTRY

11.5.6.1 LATIN AMERICA

11.5.6.1.1 LATIN AMERICA WAREHOUSE ROBOTICS MARKET, BY TYPES

11.5.6.1.2 LATIN AMERICA WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.5.6.1.2.1 LATIN AMERICA SOFTWARE MARKET, BY OFFERINGS

11.5.6.1.3 LATIN AMERICA WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.5.6.1.4 LATIN AMERICA WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.5.6.1.5 LATIN AMERICA WAREHOUSE ROBOTICS MARKET, BY END USER

11.5.6.2 MIDDLE EAST

11.5.6.2.1 MIDDLE EAST WAREHOUSE ROBOTICS MARKET, BY TYPES

11.5.6.2.2 MIDDLE EAST WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.5.6.2.2.1 MIDDLE EAST SOFTWARE MARKET, BY OFFERINGS

11.5.6.2.3 MIDDLE EAST WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.5.6.2.4 MIDDLE EAST WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.5.6.2.5 MIDDLE EAST WAREHOUSE ROBOTICS MARKET, BY END USER

11.5.6.3 AFRICA

11.5.6.3.1 AFRICA WAREHOUSE ROBOTICS MARKET, BY TYPES

11.5.6.3.2 AFRICA WAREHOUSE ROBOTICS MARKET, BY OFFERINGS

11.5.6.3.2.1 AFRICA SOFTWARE MARKET, BY OFFERINGS

11.5.6.3.3 AFRICA WAREHOUSE ROBOTICS MARKET, BY PAYLOAD CAPACITY

11.5.6.3.4 AFRICA WAREHOUSE ROBOTICS MARKET, BY APPLICATION

11.5.6.3.5 AFRICA WAREHOUSE ROBOTICS MARKET, BY END USER

12 COMPANY PROFILES

12.1 KUKA AG

12.1.1 COMPANY OVERVIEW

12.1.2 COMPANY SNAPSHOT

12.1.3 OPERATING BUSINESS SEGMENTS

12.1.4 PRODUCT PORTFOLIO

12.1.5 BUSINESS PERFORMANCE

12.1.6 BUSINESS SEGMENTS

12.1.7 GEOGRAPHIC SEGMENTS

12.1.8 KEY STRATEGIC MOVES AND DEVELOPMENT

12.1.9 PRIMARY MARKET COMPETITORS

12.2 ABB LTD.

12.2.1 COMPANY OVERVIEW

12.2.2 COMPANY SNAPSHOT

12.2.3 OPERATING BUSINESS SEGMENTS

12.2.4 PRODUCT PORTFOLIO

12.2.5 BUSINESS PERFORMANCE

12.2.6 BUSINESS SEGMENTS

12.2.7 GEOGRAPHIC SEGMENTS

12.2.8 KEY STRATEGIC MOVES AND DEVELOPMENT

12.2.9 PRIMARY MARKET COMPETITORS

12.3 FANUC CORPORATION

12.3.1 COMPANY OVERVIEW

12.3.2 COMPANY SNAPSHOT

12.3.3 OPERATING BUSINESS SEGMENTS

12.3.4 PRODUCT PORTFOLIO

12.3.5 BUSINESS PERFORMANCE

12.3.6 BUSINESS SEGMENTS

12.3.7 GEOGRAPHIC SEGMENTS

12.3.8 KEY STRATEGIC MOVES AND DEVELOPMENT

12.3.9 PRIMARY MARKET COMPETITORS

12.4 GEEKPLUS TECHNOLOGY CO., LTD.

12.4.1 COMPANY OVERVIEW

12.4.2 COMPANY SNAPSHOT

12.4.3 OPERATING BUSINESS SEGMENTS

12.4.4 PRODUCT PORTFOLIO

12.4.5 BUSINESS PERFORMANCE

12.4.6 BUSINESS SEGMENTS

12.4.7 GEOGRAPHIC SEGMENTS

12.4.8 KEY STRATEGIC MOVES AND DEVELOPMENT

12.4.9 PRIMARY MARKET COMPETITORS

12.5 BASTIAN SOLUTIONS, LLC

12.5.1 COMPANY OVERVIEW

12.5.2 COMPANY SNAPSHOT

12.5.3 OPERATING BUSINESS SEGMENTS

12.5.4 PRODUCT PORTFOLIO

12.5.5 BUSINESS PERFORMANCE

12.5.6 BUSINESS SEGMENTS

12.5.7 GEOGRAPHIC SEGMENTS

12.5.8 KEY STRATEGIC MOVES AND DEVELOPMENT

12.5.9 PRIMARY MARKET COMPETITORS

12.6 OMRON CORPORATION

12.6.1 COMPANY OVERVIEW

12.6.2 COMPANY SNAPSHOT

12.6.3 OPERATING BUSINESS SEGMENTS

12.6.4 PRODUCT PORTFOLIO

12.6.5 BUSINESS PERFORMANCE

12.6.6 BUSINESS SEGMENTS

12.6.7 GEOGRAPHIC SEGMENTS

12.6.8 KEY STRATEGIC MOVES AND DEVELOPMENT

12.6.9 PRIMARY MARKET COMPETITORS

12.7 JBT CORPORATION

12.7.1 COMPANY OVERVIEW

12.7.2 COMPANY SNAPSHOT

12.7.3 OPERATING BUSINESS SEGMENTS

12.7.4 PRODUCT PORTFOLIO

12.7.5 BUSINESS PERFORMANCE

12.7.6 BUSINESS SEGMENTS

12.7.7 GEOGRAPHIC SEGMENTS

12.7.8 KEY STRATEGIC MOVES AND DEVELOPMENT

12.7.9 PRIMARY MARKET COMPETITORS

12.8 TERADYNE INC.

12.8.1 COMPANY OVERVIEW

12.8.2 COMPANY SNAPSHOT

12.8.3 OPERATING BUSINESS SEGMENTS

12.8.4 PRODUCT PORTFOLIO

12.8.5 BUSINESS PERFORMANCE

12.8.6 BUSINESS SEGMENTS

12.8.7 GEOGRAPHIC SEGMENTS

12.8.8 KEY STRATEGIC MOVES AND DEVELOPMENT

12.8.9 PRIMARY MARKET COMPETITORS

12.9 DOOSAN ROBOTICS INC.

12.9.1 COMPANY OVERVIEW

12.9.2 COMPANY SNAPSHOT

12.9.3 OPERATING BUSINESS SEGMENTS

12.9.4 PRODUCT PORTFOLIO

12.9.5 BUSINESS PERFORMANCE

12.9.6 BUSINESS SEGMENTS

12.9.7 GEOGRAPHIC SEGMENTS

12.9.8 KEY STRATEGIC MOVES AND DEVELOPMENT

12.9.9 PRIMARY MARKET COMPETITORS

12.10 GREYORANGE

12.10.1 COMPANY OVERVIEW

12.10.2 COMPANY SNAPSHOT

12.10.3 OPERATING BUSINESS SEGMENTS

12.10.4 PRODUCT PORTFOLIO

12.10.5 BUSINESS PERFORMANCE

12.10.6 BUSINESS SEGMENTS

12.10.7 GEOGRAPHIC SEGMENTS

12.10.8 KEY STRATEGIC MOVES AND DEVELOPMENT

12.10.9 PRIMARY MARKET COMPETITORS

12.11 LOCUS ROBOTICS

12.11.1 COMPANY OVERVIEW

12.11.2 COMPANY SNAPSHOT

12.11.3 OPERATING BUSINESS SEGMENTS

12.11.4 PRODUCT PORTFOLIO

12.11.5 BUSINESS PERFORMANCE

12.11.6 BUSINESS SEGMENTS

12.11.7 GEOGRAPHIC SEGMENTS

12.11.8 KEY STRATEGIC MOVES AND DEVELOPMENT

12.11.9 PRIMARY MARKET COMPETITORS

12.12 SEEGRID CORPORATION

12.12.1 COMPANY OVERVIEW

12.12.2 COMPANY SNAPSHOT

12.12.3 OPERATING BUSINESS SEGMENTS

12.12.4 PRODUCT PORTFOLIO

12.12.5 BUSINESS PERFORMANCE

12.12.6 BUSINESS SEGMENTS

12.12.7 GEOGRAPHIC SEGMENTS

12.12.8 KEY STRATEGIC MOVES AND DEVELOPMENT

12.12.9 PRIMARY MARKET COMPETITORS

12.13 HIKROBOT

12.13.1 COMPANY OVERVIEW

12.13.2 COMPANY SNAPSHOT

12.13.3 OPERATING BUSINESS SEGMENTS

12.13.4 PRODUCT PORTFOLIO

12.13.5 BUSINESS PERFORMANCE

12.13.6 BUSINESS SEGMENTS

12.13.7 GEOGRAPHIC SEGMENTS

12.13.8 KEY STRATEGIC MOVES AND DEVELOPMENT

12.13.9 PRIMARY MARKET COMPETITORS

12.14 DEMATIC

12.14.1 COMPANY OVERVIEW

12.14.2 COMPANY SNAPSHOT

12.14.3 OPERATING BUSINESS SEGMENTS

12.14.4 PRODUCT PORTFOLIO

12.14.5 BUSINESS PERFORMANCE

12.14.6 BUSINESS SEGMENTS

12.14.7 GEOGRAPHIC SEGMENTS

12.14.8 KEY STRATEGIC MOVES AND DEVELOPMENT

12.14.9 PRIMARY MARKET COMPETITORS

12.15 VANDERLANDE INDUSTRIES B.V.

12.15.1 COMPANY OVERVIEW

12.15.2 COMPANY SNAPSHOT

12.15.3 OPERATING BUSINESS SEGMENTS

12.15.4 PRODUCT PORTFOLIO

12.15.5 BUSINESS PERFORMANCE

12.15.6 BUSINESS SEGMENTS

12.15.7 GEOGRAPHIC SEGMENTS

12.15.8 KEY STRATEGIC MOVES AND DEVELOPMENT

12.15.9 PRIMARY MARKET COMPETITORS

LIST OF TABLES

TABLE 1. GLOBAL WAREHOUSE ROBOTICS MARKET VALUE, BY TYPES, 2024-2030, (MILLION USD)

TABLE 2. GLOBAL WAREHOUSE ROBOTICS MARKET VALUE, BY TYPES, 2024-2030, (UNITS)

TABLE 3. AUTOMATED GUIDED VEHICLES (AGVS) MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 4. AUTOMATED GUIDED VEHICLES (AGVS) MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 5. NORTH AMERICA AUTOMATED GUIDED VEHICLES (AGVS), MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 6. NORTH AMERICA AUTOMATED GUIDED VEHICLES (AGVS), MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 7. EUROPE AUTOMATED GUIDED VEHICLES (AGVS), MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 8. EUROPE AUTOMATED GUIDED VEHICLES (AGVS), MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 9. ASIA-PACIFIC AUTOMATED GUIDED VEHICLES (AGVS), MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 10. ASIA-PACIFIC AUTOMATED GUIDED VEHICLES (AGVS), MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 11. REST OF THE WORLD AUTOMATED GUIDED VEHICLES (AGVS), MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 12. REST OF THE WORLD AUTOMATED GUIDED VEHICLES (AGVS), MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 13. AUTONOMOUS MOBILE ROBOTS (AMRS) MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 14. AUTONOMOUS MOBILE ROBOTS (AMRS) MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 15. NORTH AMERICA AUTONOMOUS MOBILE ROBOTS (AMRS), MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 16. NORTH AMERICA AUTONOMOUS MOBILE ROBOTS (AMRS), MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 17. EUROPE AUTONOMOUS MOBILE ROBOTS (AMRS), MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 18. EUROPE AUTONOMOUS MOBILE ROBOTS (AMRS), MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 19. ASIA-PACIFIC AUTONOMOUS MOBILE ROBOTS (AMRS), MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 20. ASIA-PACIFIC AUTONOMOUS MOBILE ROBOTS (AMRS), MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 21. REST OF THE WORLD AUTONOMOUS MOBILE ROBOTS (AMRS), MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 22. REST OF THE WORLD AUTONOMOUS MOBILE ROBOTS (AMRS), MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 23. ARTICULATED ROBOTS MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 24. ARTICULATED ROBOTS MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 25. NORTH AMERICA ARTICULATED ROBOTS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 26. NORTH AMERICA ARTICULATED ROBOTS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 27. EUROPE ARTICULATED ROBOTS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 28. EUROPE ARTICULATED ROBOTS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 29. ASIA-PACIFIC ARTICULATED ROBOTS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 30. ASIA-PACIFIC ARTICULATED ROBOTS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 31. REST OF THE WORLD ARTICULATED ROBOTS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 32. REST OF THE WORLD ARTICULATED ROBOTS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 33. COLLABORATIVE ROBOTS (COBOT) MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 34. COLLABORATIVE ROBOTS (COBOT) MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 35. NORTH AMERICA COLLABORATIVE ROBOTS (COBOT), MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 36. NORTH AMERICA COLLABORATIVE ROBOTS (COBOT), MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 37. EUROPE COLLABORATIVE ROBOTS (COBOT), MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 38. EUROPE COLLABORATIVE ROBOTS (COBOT), MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 39. ASIA-PACIFIC COLLABORATIVE ROBOTS (COBOT), MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 40. ASIA-PACIFIC COLLABORATIVE ROBOTS (COBOT), MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 41. REST OF THE WORLD COLLABORATIVE ROBOTS (COBOT), MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 42. REST OF THE WORLD COLLABORATIVE ROBOTS (COBOT), MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 43. SCARA ROBOTS AND CYLINDRICAL ROBOT MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 44. SCARA ROBOTS AND CYLINDRICAL ROBOT MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 45. NORTH AMERICA SCARA ROBOTS AND CYLINDRICAL ROBOT, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 46. NORTH AMERICA SCARA ROBOTS AND CYLINDRICAL ROBOT, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 47. EUROPE SCARA ROBOTS AND CYLINDRICAL ROBOT, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 48. EUROPE SCARA ROBOTS AND CYLINDRICAL ROBOT, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 49. ASIA-PACIFIC SCARA ROBOTS AND CYLINDRICAL ROBOT, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 50. ASIA-PACIFIC SCARA ROBOTS AND CYLINDRICAL ROBOT, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 51. REST OF THE WORLD SCARA ROBOTS AND CYLINDRICAL ROBOT, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 52. REST OF THE WORLD SCARA ROBOTS AND CYLINDRICAL ROBOT, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 53. OTHERS MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 54. OTHERS MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 55. NORTH AMERICA OTHERS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 56. NORTH AMERICA OTHERS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 57. EUROPE OTHERS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 58. EUROPE OTHERS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 59. ASIA-PACIFIC OTHERS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 60. ASIA-PACIFIC OTHERS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 61. REST OF THE WORLD OTHERS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 62. REST OF THE WORLD OTHERS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 63. GLOBAL WAREHOUSE ROBOTICS MARKET VALUE, BY OFFERINGS, 2024-2030, (MILLION USD)

TABLE 64. GLOBAL WAREHOUSE ROBOTICS MARKET VALUE, BY OFFERINGS, 2024-2030, (UNITS)

TABLE 65. HARDWARE MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 66. HARDWARE MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 67. NORTH AMERICA HARDWARE, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 68. NORTH AMERICA HARDWARE, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 69. EUROPE HARDWARE, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 70. EUROPE HARDWARE, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 71. ASIA-PACIFIC HARDWARE, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 72. ASIA-PACIFIC HARDWARE, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 73. REST OF THE WORLD HARDWARE, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 74. REST OF THE WORLD HARDWARE, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 75. SOFTWARE MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 76. SOFTWARE MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 77. NORTH AMERICA SOFTWARE, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 78. NORTH AMERICA SOFTWARE, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 79. EUROPE SOFTWARE, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 80. EUROPE SOFTWARE, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 81. ASIA-PACIFIC SOFTWARE, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 82. ASIA-PACIFIC SOFTWARE, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 83. REST OF THE WORLD SOFTWARE, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 84. REST OF THE WORLD SOFTWARE, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 85. SERVICES MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 86. SERVICES MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 87. NORTH AMERICA SERVICES, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 88. NORTH AMERICA SERVICES, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 89. EUROPE SERVICES, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 90. EUROPE SERVICES, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 91. ASIA-PACIFIC SERVICES, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 92. ASIA-PACIFIC SERVICES, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 93. REST OF THE WORLD SERVICES, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 94. REST OF THE WORLD SERVICES, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 95. GLOBAL WAREHOUSE ROBOTICS MARKET VALUE, BY PAYLOAD CAPACITY, 2024-2030, (MILLION USD)

TABLE 96. GLOBAL WAREHOUSE ROBOTICS MARKET VALUE, BY PAYLOAD CAPACITY, 2024-2030, (UNITS)

TABLE 97. LESS 100 KG MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 98. LESS 100 KG MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 99. NORTH AMERICA LESS 100 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 100. NORTH AMERICA LESS 100 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 101. EUROPE LESS 100 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 102. EUROPE LESS 100 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 103. ASIA-PACIFIC LESS 100 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 104. ASIA-PACIFIC LESS 100 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 105. REST OF THE WORLD LESS 100 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 106. REST OF THE WORLD LESS 100 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 107. 101-200 KG MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 108. 101-200 KG MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 109. NORTH AMERICA 101-200 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 110. NORTH AMERICA 101-200 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 111. EUROPE 101-200 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 112. EUROPE 101-200 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 113. ASIA-PACIFIC 101-200 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 114. ASIA-PACIFIC 101-200 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 115. REST OF THE WORLD 101-200 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 116. REST OF THE WORLD 101-200 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 117. 201-500 KG MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 118. 201-500 KG MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 119. NORTH AMERICA 201-500 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 120. NORTH AMERICA 201-500 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 121. EUROPE 201-500 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 122. EUROPE 201-500 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 123. ASIA-PACIFIC 201-500 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 124. ASIA-PACIFIC 201-500 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 125. REST OF THE WORLD 201-500 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 126. REST OF THE WORLD 201-500 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 127. 501-1000 KG MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 128. 501-1000 KG MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 129. NORTH AMERICA 501-1000 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 130. NORTH AMERICA 501-1000 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 131. EUROPE 501-1000 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 132. EUROPE 501-1000 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 133. ASIA-PACIFIC 501-1000 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 134. ASIA-PACIFIC 501-1000 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 135. REST OF THE WORLD 501-1000 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 136. REST OF THE WORLD 501-1000 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 137. 1001-2000 KG MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 138. 1001-2000 KG MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 139. NORTH AMERICA 1001-2000 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 140. NORTH AMERICA 1001-2000 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 141. EUROPE 1001-2000 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 142. EUROPE 1001-2000 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 143. ASIA-PACIFIC 1001-2000 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 144. ASIA-PACIFIC 1001-2000 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 145. REST OF THE WORLD 1001-2000 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 146. REST OF THE WORLD 1001-2000 KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 147. 2001-5000KG MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 148. 2001-5000KG MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 149. NORTH AMERICA 2001-5000KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 150. NORTH AMERICA 2001-5000KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 151. EUROPE 2001-5000KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 152. EUROPE 2001-5000KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 153. ASIA-PACIFIC 2001-5000KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 154. ASIA-PACIFIC 2001-5000KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 155. REST OF THE WORLD 2001-5000KG, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 156. REST OF THE WORLD 2001-5000KG, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 157. GLOBAL WAREHOUSE ROBOTICS MARKET VALUE, BY APPLICATION, 2024-2030, (MILLION USD)

TABLE 158. GLOBAL WAREHOUSE ROBOTICS MARKET VALUE, BY APPLICATION, 2024-2030, (UNITS)

TABLE 159. PALLETIZING AND DEPALLETIZING MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 160. PALLETIZING AND DEPALLETIZING MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 161. NORTH AMERICA PALLETIZING AND DEPALLETIZING, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 162. NORTH AMERICA PALLETIZING AND DEPALLETIZING, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 163. EUROPE PALLETIZING AND DEPALLETIZING, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 164. EUROPE PALLETIZING AND DEPALLETIZING, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 165. ASIA-PACIFIC PALLETIZING AND DEPALLETIZING, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 166. ASIA-PACIFIC PALLETIZING AND DEPALLETIZING, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 167. REST OF THE WORLD PALLETIZING AND DEPALLETIZING, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 168. REST OF THE WORLD PALLETIZING AND DEPALLETIZING, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 169. SORTING AND PACKAGING MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 170. SORTING AND PACKAGING MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 171. NORTH AMERICA SORTING AND PACKAGING, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 172. NORTH AMERICA SORTING AND PACKAGING, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 173. EUROPE SORTING AND PACKAGING, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 174. EUROPE SORTING AND PACKAGING, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 175. ASIA-PACIFIC SORTING AND PACKAGING, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 176. ASIA-PACIFIC SORTING AND PACKAGING, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 177. REST OF THE WORLD SORTING AND PACKAGING, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 178. REST OF THE WORLD SORTING AND PACKAGING, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 179. PICKING AND PLACING MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 180. PICKING AND PLACING MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 181. NORTH AMERICA PICKING AND PLACING, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 182. NORTH AMERICA PICKING AND PLACING, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 183. EUROPE PICKING AND PLACING, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 184. EUROPE PICKING AND PLACING, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 185. ASIA-PACIFIC PICKING AND PLACING, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 186. ASIA-PACIFIC PICKING AND PLACING, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 187. REST OF THE WORLD PICKING AND PLACING, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 188. REST OF THE WORLD PICKING AND PLACING, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 189. TRANSPORTATION MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 190. TRANSPORTATION MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 191. NORTH AMERICA TRANSPORTATION, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 192. NORTH AMERICA TRANSPORTATION, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 193. EUROPE TRANSPORTATION, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 194. EUROPE TRANSPORTATION, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 195. ASIA-PACIFIC TRANSPORTATION, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 196. ASIA-PACIFIC TRANSPORTATION, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 197. REST OF THE WORLD TRANSPORTATION, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 198. REST OF THE WORLD TRANSPORTATION, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 199. GLOBAL WAREHOUSE ROBOTICS MARKET VALUE, BY END USER, 2024-2030, (MILLION USD)

TABLE 200. GLOBAL WAREHOUSE ROBOTICS MARKET VALUE, BY END USER, 2024-2030, (UNITS)

TABLE 201. E-COMMERCE MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 202. E-COMMERCE MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 203. NORTH AMERICA E-COMMERCE, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 204. NORTH AMERICA E-COMMERCE, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 205. EUROPE E-COMMERCE, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 206. EUROPE E-COMMERCE, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 207. ASIA-PACIFIC E-COMMERCE, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 208. ASIA-PACIFIC E-COMMERCE, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 209. REST OF THE WORLD E-COMMERCE, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 210. REST OF THE WORLD E-COMMERCE, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 211. AUTOMOTIVE MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 212. AUTOMOTIVE MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 213. NORTH AMERICA AUTOMOTIVE, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 214. NORTH AMERICA AUTOMOTIVE, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 215. EUROPE AUTOMOTIVE, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 216. EUROPE AUTOMOTIVE, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 217. ASIA-PACIFIC AUTOMOTIVE, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 218. ASIA-PACIFIC AUTOMOTIVE, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 219. REST OF THE WORLD AUTOMOTIVE, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 220. REST OF THE WORLD AUTOMOTIVE, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 221. FOOD AND BEVERAGES MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 222. FOOD AND BEVERAGES MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 223. NORTH AMERICA FOOD AND BEVERAGES, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 224. NORTH AMERICA FOOD AND BEVERAGES, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 225. EUROPE FOOD AND BEVERAGES, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 226. EUROPE FOOD AND BEVERAGES, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 227. ASIA-PACIFIC FOOD AND BEVERAGES, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 228. ASIA-PACIFIC FOOD AND BEVERAGES, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 229. REST OF THE WORLD FOOD AND BEVERAGES, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 230. REST OF THE WORLD FOOD AND BEVERAGES, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 231. PHARMACEUTICAL MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 232. PHARMACEUTICAL MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 233. NORTH AMERICA PHARMACEUTICAL, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 234. NORTH AMERICA PHARMACEUTICAL, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 235. EUROPE PHARMACEUTICAL, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 236. EUROPE PHARMACEUTICAL, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 237. ASIA-PACIFIC PHARMACEUTICAL, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 238. ASIA-PACIFIC PHARMACEUTICAL, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 239. REST OF THE WORLD PHARMACEUTICAL, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 240. REST OF THE WORLD PHARMACEUTICAL, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 241. CHEMICAL AND MATERIALS MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 242. CHEMICAL AND MATERIALS MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 243. NORTH AMERICA CHEMICAL AND MATERIALS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 244. NORTH AMERICA CHEMICAL AND MATERIALS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 245. EUROPE CHEMICAL AND MATERIALS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 246. EUROPE CHEMICAL AND MATERIALS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 247. ASIA-PACIFIC CHEMICAL AND MATERIALS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 248. ASIA-PACIFIC CHEMICAL AND MATERIALS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 249. REST OF THE WORLD CHEMICAL AND MATERIALS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 250. REST OF THE WORLD CHEMICAL AND MATERIALS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 251. SEMICONDUCTOR AND ELECTRONICS MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 252. SEMICONDUCTOR AND ELECTRONICS MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 253. NORTH AMERICA SEMICONDUCTOR AND ELECTRONICS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 254. NORTH AMERICA SEMICONDUCTOR AND ELECTRONICS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 255. EUROPE SEMICONDUCTOR AND ELECTRONICS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 256. EUROPE SEMICONDUCTOR AND ELECTRONICS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 257. ASIA-PACIFIC SEMICONDUCTOR AND ELECTRONICS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 258. ASIA-PACIFIC SEMICONDUCTOR AND ELECTRONICS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 259. REST OF THE WORLD SEMICONDUCTOR AND ELECTRONICS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 260. REST OF THE WORLD SEMICONDUCTOR AND ELECTRONICS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 261. OTHERS MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 262. OTHERS MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 263. NORTH AMERICA OTHERS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 264. NORTH AMERICA OTHERS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 265. EUROPE OTHERS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 266. EUROPE OTHERS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 267. ASIA-PACIFIC OTHERS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 268. ASIA-PACIFIC OTHERS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 269. REST OF THE WORLD OTHERS, MARKET VALUE, BY COUNTRY, 2024-2030, (MILLION USD)

TABLE 270. REST OF THE WORLD OTHERS, MARKET VALUE, BY COUNTRY, 2024-2030, (UNITS)

TABLE 271. GLOBAL WAREHOUSE ROBOTICS MARKET VALUE, BY REGION, 2024-2030, (MILLION USD)

TABLE 272. GLOBAL WAREHOUSE ROBOTICS MARKET VALUE, BY REGION, 2024-2030, (UNITS)

TABLE 273. NORTH AMERICA WAREHOUSE ROBOTICS MARKET VALUE, BY TYPES, 2024-2030, (MILLION USD)

TABLE 274. NORTH AMERICA WAREHOUSE ROBOTICS MARKET VALUE, BY TYPES, 2024-2030, (UNITS)

TABLE 275. NORTH AMERICA WAREHOUSE ROBOTICS MARKET VALUE, BY OFFERINGS, 2024-2030, (MILLION USD)

TABLE 276. NORTH AMERICA WAREHOUSE ROBOTICS MARKET VALUE, BY OFFERINGS, 2024-2030, (UNITS)

TABLE 277. NORTH AMERICA WAREHOUSE ROBOTICS MARKET VALUE, BY PAYLOAD CAPACITY, 2024-2030, (MILLION USD)

TABLE 278. NORTH AMERICA WAREHOUSE ROBOTICS MARKET VALUE, BY PAYLOAD CAPACITY, 2024-2030, (UNITS)

TABLE 279. NORTH AMERICA WAREHOUSE ROBOTICS MARKET VALUE, BY APPLICATION, 2024-2030, (MILLION USD)

TABLE 280. NORTH AMERICA WAREHOUSE ROBOTICS MARKET VALUE, BY APPLICATION, 2024-2030, (UNITS)

TABLE 281. NORTH AMERICA WAREHOUSE ROBOTICS MARKET VALUE, BY END USER, 2024-2030, (MILLION USD)

TABLE 282. NORTH AMERICA WAREHOUSE ROBOTICS MARKET VALUE, BY END USER, 2024-2030, (UNITS)

TABLE 283. UNITED STATES WAREHOUSE ROBOTICS MARKET VALUE, BY TYPES, 2024-2030, (MILLION USD)

TABLE 284. UNITED STATES WAREHOUSE ROBOTICS MARKET VALUE, BY TYPES, 2024-2030, (UNITS)

TABLE 285. UNITED STATES WAREHOUSE ROBOTICS MARKET VALUE, BY OFFERINGS, 2024-2030, (MILLION USD)

TABLE 286. UNITED STATES WAREHOUSE ROBOTICS MARKET VALUE, BY OFFERINGS, 2024-2030, (UNITS)

TABLE 287. UNITED STATES WAREHOUSE ROBOTICS MARKET VALUE, BY PAYLOAD CAPACITY, 2024-2030, (MILLION USD)

TABLE 288. UNITED STATES WAREHOUSE ROBOTICS MARKET VALUE, BY PAYLOAD CAPACITY, 2024-2030, (UNITS)

TABLE 289. UNITED STATES WAREHOUSE ROBOTICS MARKET VALUE, BY APPLICATION, 2024-2030, (MILLION USD)

TABLE 290. UNITED STATES WAREHOUSE ROBOTICS MARKET VALUE, BY APPLICATION, 2024-2030, (UNITS)

TABLE 291. UNITED STATES WAREHOUSE ROBOTICS MARKET VALUE, BY END USER, 2024-2030, (MILLION USD)

TABLE 292. UNITED STATES WAREHOUSE ROBOTICS MARKET VALUE, BY END USER, 2024-2030, (UNITS)

TABLE 293. CANADA WAREHOUSE ROBOTICS MARKET VALUE, BY TYPES, 2024-2030, (MILLION USD)

TABLE 294. CANADA WAREHOUSE ROBOTICS MARKET VALUE, BY TYPES, 2024-2030, (UNITS)

TABLE 295. CANADA WAREHOUSE ROBOTICS MARKET VALUE, BY OFFERINGS, 2024-2030, (MILLION USD)

TABLE 296. CANADA WAREHOUSE ROBOTICS MARKET VALUE, BY OFFERINGS, 2024-2030, (UNITS)

TABLE 297. CANADA WAREHOUSE ROBOTICS MARKET VALUE, BY PAYLOAD CAPACITY, 2024-2030, (MILLION USD)

TABLE 298. CANADA WAREHOUSE ROBOTICS MARKET VALUE, BY PAYLOAD CAPACITY, 2024-2030, (UNITS)

TABLE 299. CANADA WAREHOUSE ROBOTICS MARKET VALUE, BY APPLICATION, 2024-2030, (MILLION USD)

TABLE 300. CANADA WAREHOUSE ROBOTICS MARKET VALUE, BY APPLICATION, 2024-2030, (UNITS)

TABLE 301. CANADA WAREHOUSE ROBOTICS MARKET VALUE, BY END USER, 2024-2030, (MILLION USD)

TABLE 302. CANADA WAREHOUSE ROBOTICS MARKET VALUE, BY END USER, 2024-2030, (UNITS)

TABLE 303. MEXICO WAREHOUSE ROBOTICS MARKET VALUE, BY TYPES, 2024-2030, (MILLION USD)

TABLE 304. MEXICO WAREHOUSE ROBOTICS MARKET VALUE, BY TYPES, 2024-2030, (UNITS)

TABLE 305. MEXICO WAREHOUSE ROBOTICS MARKET VALUE, BY OFFERINGS, 2024-2030, (MILLION USD)

TABLE 306. MEXICO WAREHOUSE ROBOTICS MARKET VALUE, BY OFFERINGS, 2024-2030, (UNITS)

TABLE 307. MEXICO WAREHOUSE ROBOTICS MARKET VALUE, BY PAYLOAD CAPACITY, 2024-2030, (MILLION USD)

TABLE 308. MEXICO WAREHOUSE ROBOTICS MARKET VALUE, BY PAYLOAD CAPACITY, 2024-2030, (UNITS)

TABLE 309. MEXICO WAREHOUSE ROBOTICS MARKET VALUE, BY APPLICATION, 2024-2030, (MILLION USD)

TABLE 310. MEXICO WAREHOUSE ROBOTICS MARKET VALUE, BY APPLICATION, 2024-2030, (UNITS)

TABLE 311. MEXICO WAREHOUSE ROBOTICS MARKET VALUE, BY END USER, 2024-2030, (MILLION USD)

TABLE 312. MEXICO WAREHOUSE ROBOTICS MARKET VALUE, BY END USER, 2024-2030, (UNITS)

TABLE 313. EUROPE WAREHOUSE ROBOTICS MARKET VALUE, BY TYPES, 2024-2030, (MILLION USD)

TABLE 314. EUROPE WAREHOUSE ROBOTICS MARKET VALUE, BY TYPES, 2024-2030, (UNITS)

TABLE 315. EUROPE WAREHOUSE ROBOTICS MARKET VALUE, BY OFFERINGS, 2024-2030, (MILLION USD)

TABLE 316. EUROPE WAREHOUSE ROBOTICS MARKET VALUE, BY OFFERINGS, 2024-2030, (UNITS)

TABLE 317. EUROPE WAREHOUSE ROBOTICS MARKET VALUE, BY PAYLOAD CAPACITY, 2024-2030, (MILLION USD)

TABLE 318. EUROPE WAREHOUSE ROBOTICS MARKET VALUE, BY PAYLOAD CAPACITY, 2024-2030, (UNITS)

TABLE 319. EUROPE WAREHOUSE ROBOTICS MARKET VALUE, BY APPLICATION, 2024-2030, (MILLION USD)

TABLE 320. EUROPE WAREHOUSE ROBOTICS MARKET VALUE, BY APPLICATION, 2024-2030, (UNITS)

TABLE 321. EUROPE WAREHOUSE ROBOTICS MARKET VALUE, BY END USER, 2024-2030, (MILLION USD)

TABLE 322. EUROPE WAREHOUSE ROBOTICS MARKET VALUE, BY END USER, 2024-2030, (UNITS)

TABLE 323. GERMANY WAREHOUSE ROBOTICS MARKET VALUE, BY TYPES, 2024-2030, (MILLION USD)

TABLE 324. GERMANY WAREHOUSE ROBOTICS MARKET VALUE, BY TYPES, 2024-2030, (UNITS)

TABLE 325. GERMANY WAREHOUSE ROBOTICS MARKET VALUE, BY OFFERINGS, 2024-2030, (MILLION USD)

TABLE 326. GERMANY WAREHOUSE ROBOTICS MARKET VALUE, BY OFFERINGS, 2024-2030, (UNITS)

TABLE 327. GERMANY WAREHOUSE ROBOTICS MARKET VALUE, BY PAYLOAD CAPACITY, 2024-2030, (MILLION USD)

TABLE 328. GERMANY WAREHOUSE ROBOTICS MARKET VALUE, BY PAYLOAD CAPACITY, 2024-2030, (UNITS)

TABLE 329. GERMANY WAREHOUSE ROBOTICS MARKET VALUE, BY APPLICATION, 2024-2030, (MILLION USD)

TABLE 330. GERMANY WAREHOUSE ROBOTICS MARKET VALUE, BY APPLICATION, 2024-2030, (UNITS)

TABLE 331. GERMANY WAREHOUSE ROBOTICS MARKET VALUE, BY END USER, 2024-2030, (MILLION USD)

TABLE 332. GERMANY WAREHOUSE ROBOTICS MARKET VALUE, BY END USER, 2024-2030, (UNITS)

TABLE 333. FRANCE WAREHOUSE ROBOTICS MARKET VALUE, BY TYPES, 2024-2030, (MILLION USD)

TABLE 334. FRANCE WAREHOUSE ROBOTICS MARKET VALUE, BY TYPES, 2024-2030, (UNITS)

TABLE 335. FRANCE WAREHOUSE ROBOTICS MARKET VALUE, BY OFFERINGS, 2024-2030, (MILLION USD)

TABLE 336. FRANCE WAREHOUSE ROBOTICS MARKET VALUE, BY OFFERINGS, 2024-2030, (UNITS)

TABLE 337. FRANCE WAREHOUSE ROBOTICS MARKET VALUE, BY PAYLOAD CAPACITY, 2024-2030, (MILLION USD)

TABLE 338. FRANCE WAREHOUSE ROBOTICS MARKET VALUE, BY PAYLOAD CAPACITY, 2024-2030, (UNITS)

TABLE 339. FRANCE WAREHOUSE ROBOTICS MARKET VALUE, BY APPLICATION, 2024-2030, (MILLION USD)

TABLE 340. FRANCE WAREHOUSE ROBOTICS MARKET VALUE, BY APPLICATION, 2024-2030, (UNITS)

TABLE 341. FRANCE WAREHOUSE ROBOTICS MARKET VALUE, BY END USER, 2024-2030, (MILLION USD)

TABLE 342. FRANCE WAREHOUSE ROBOTICS MARKET VALUE, BY END USER, 2024-2030, (UNITS)

TABLE 343. ITALY WAREHOUSE ROBOTICS MARKET VALUE, BY TYPES, 2024-2030, (MILLION USD)

TABLE 344. ITALY WAREHOUSE ROBOTICS MARKET VALUE, BY TYPES, 2024-2030, (UNITS)

TABLE 345. ITALY WAREHOUSE ROBOTICS MARKET VALUE, BY OFFERINGS, 2024-2030, (MILLION USD)

TABLE 346. ITALY WAREHOUSE ROBOTICS MARKET VALUE, BY OFFERINGS, 2024-2030, (UNITS)

TABLE 347. ITALY WAREHOUSE ROBOTICS MARKET VALUE, BY PAYLOAD CAPACITY, 2024-2030, (MILLION USD)

TABLE 348. ITALY WAREHOUSE ROBOTICS MARKET VALUE, BY PAYLOAD CAPACITY, 2024-2030, (UNITS)