Unlocking Real-Time Supply Chain Insights Through IoT Integration in ERP Software

15-May-2025

The rapid pace of technological advancements has led to a significant transformation in how businesses manage their operations. One of the most profound changes has come through the integration of the Internet of Things (IoT) in Enterprise Resource Planning (ERP) software. IoT integration in ERP systems is unlocking real-time data insights that are revolutionizing supply chain management. This technology allows businesses to track inventory, manage resources, and predict potential disruptions in real-time, helping companies make more informed, proactive decisions.

This blog explores how IoT integration in ERP systems is transforming supply chains, discuss the latest trends and company launches in this field, and examine the impact of real-time data on decision-making and efficiency.

Get your FREE Sample Now for the latest market share analysis and in-depth insights into the ERP Software industry.

What Is IoT Integration in ERP Software?

Before diving into the transformative benefits, it’s important to understand what IoT integration in ERP systems entails.

IoT refers to the network of interconnected devices that collect and exchange data. These devices could range from warehouse sensors that track inventory to fleet management tools that monitor vehicle conditions. When integrated into ERP software, this real-time data feeds directly into the system, enabling businesses to have a comprehensive and dynamic view of their supply chains. A 2024 U.S. Department of Commerce report highlights that 62% of U.S. manufacturers adopted IoT for real-time supply chain tracking by mid-2024, reflecting an 18% increase from 2023.

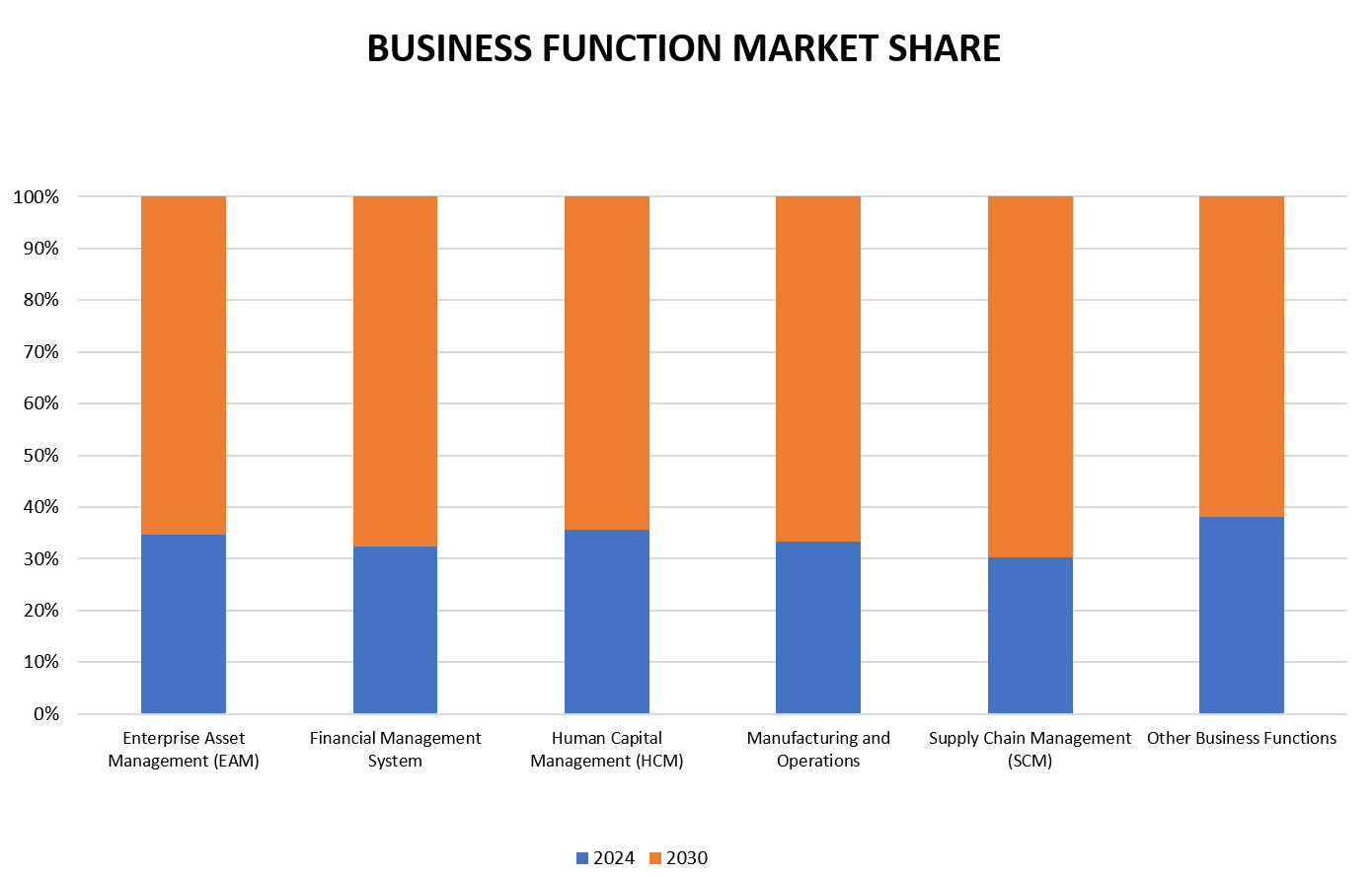

ERP systems traditionally focus on managing resources such as inventory, human resources, financials, and more. It is used for various business function with its increasing adoption rate as depicted in the pie chart below. However, the integration of IoT allows for real-time monitoring and control of physical assets, enhancing the decision-making process across various business functions. IoT-enabled ERP systems not only collect data but also analyze it to provide insights that were once impossible to gather in such detail and speed.

Why IoT Integration is Essential for Supply Chain Management

1. Real-Time Inventory Tracking

IoT sensors embedded in products or equipment can track inventory in real time, allowing businesses to know exactly where items are in the supply chain at any given moment. This eliminates the uncertainty of stock levels and ensures more efficient inventory management.

For instance, Festo’s Automation Experience (AX) Platform, launched on October 8, 2024, integrates IoT with ERP systems like SAP and Oracle to monitor equipment health in real-time. Using AI-driven sensors, this platform reduces downtime by 20% and waste by 50%, significantly enhancing the efficiency of supply chain management. By continuously monitoring inventory levels, companies can avoid stockouts or overstocking and optimize their supply chain operations.

2. Improved Forecasting and Demand Planning

Accurate forecasting is a challenge that every supply chain faces. Traditional methods rely on historical data, which may not be agile enough to adjust to sudden shifts in market demand. By integrating IoT data into ERP systems, businesses can make more accurate predictions based on real-time data from sensors tracking consumer behavior, weather patterns, and even social media trends.

The recent IFS Cloud Update on April 16, 2024, demonstrates how IoT integration can enhance supply chain forecasting. By incorporating real-time data through digital twins and advanced analytics, IFS’s enhanced ERP system enabled a 26% revenue increase in Q1 2024. The integration of real-time data into forecasting models allows businesses to better anticipate demand fluctuations, thereby improving operational efficiency.

3. Predictive Maintenance for Equipment

IoT-enabled ERP systems can predict when machinery or equipment is likely to fail based on real-time sensor data. This predictive maintenance helps businesses schedule repairs before problems arise, reducing downtime and ensuring that operations run smoothly.

For instance, Epicor Industry ERP Cloud, updated on April 23, 2024, introduced IoT capabilities to monitor manufacturing equipment in real-time. By leveraging generative AI for analytics, Epicor’s solution helped achieve a 42% increase in SaaS-based cloud revenue in 2023. Predictive maintenance capabilities built into the ERP system ensure that businesses can address maintenance issues proactively, preventing costly disruptions and extending the lifespan of critical equipment.

4. Optimizing Transportation and Fleet Management

Efficient transportation is vital for any supply chain. IoT-ERP integration allows companies to track their fleet in real time, optimizing routes and improving delivery accuracy. Real-time data on fuel usage, vehicle conditions, and driver behavior ensures businesses can reduce costs and improve service delivery.

Oracle’s Fusion Cloud SCM, which launched on January 14, 2025, enhances real-time logistics tracking and integrates blockchain for greater transparency and traceability. The system also aligns with sustainability goals, helping businesses reduce their carbon footprint by optimizing transportation routes and vehicle usage. This update reinforces the role of IoT-ERP integration in reducing inefficiencies and improving the overall supply chain performance.

5. Enhancing Transparency and Compliance

In industries such as pharmaceuticals, food, and electronics, maintaining product integrity and adhering to regulations is crucial. IoT sensors integrated into ERP systems can track environmental conditions such as temperature, humidity, and storage conditions, ensuring compliance with regulations and maintaining the quality of goods.

NetSuite’s AI-Driven ERP Enhancements, launched on March 12, 2025, added IoT-integrated features that enhance supply chain orchestration, including predictive analytics and mobile ERP apps. These innovations allow businesses to monitor the environmental conditions of sensitive products in real time, ensuring that regulatory standards are met and transparency is maintained throughout the supply chain.

Recent Trends and Developments in IoT-ERP Integration

The use of IoT in ERP systems is still evolving, with several companies making significant strides toward creating smarter, more efficient supply chains. Here are some of the latest developments:

Smart Sensors and Edge Computing

The advent of smart sensors and edge computing is further enhancing IoT-ERP integration. Edge computing allows data processing to happen closer to the source, reducing latency and enabling real-time decision-making. A 2025 Gartner report predicts that 70% of IoT-ERP systems will incorporate edge computing by 2026.

Honeywell launched a suite of IoT-enabled sensors for its ERP platform on September 10, 2024, designed for real-time monitoring of environmental conditions and asset performance, providing companies with immediate insights into potential supply chain disruptions.

5G Connectivity for Faster Data Transfer

With the rollout of 5G networks, the speed and reliability of data transfer have significantly improved, enabling faster and more efficient communication between IoT devices and ERP systems. A 2024 Federal Communications Commission report notes that 5G adoption in industrial IoT grew by 25% in 2024.

Vodafone, in partnership with several ERP providers, demonstrated 5G’s impact on IoT-ERP integration on March 5, 2025, particularly in industries requiring high-volume, real-time data monitoring, such as logistics and manufacturing.

AI and Machine Learning Integration

AI and machine learning are increasingly being incorporated into ERP systems alongside IoT to provide even more sophisticated insights and automation. A 2025 Forbes report indicates that 60% of ERP vendors now incorporate AI-driven IoT analytics, up from 45% in 2023.

SAP launched an update to its S/4HANA ERP solution on July 20, 2024, integrating AI and machine learning with IoT data to improve forecasting, inventory management, and production scheduling. This level of automation is expected to be a key trend in the future of supply chain management.

Conclusion: The Future of IoT-ERP Integration

The integration of IoT with ERP systems is fundamentally transforming supply chain management by providing real-time insights that enable businesses to optimize operations, reduce costs, and improve customer satisfaction. With the continuous advancement of IoT technologies and the introduction of edge computing, 5G, and AI, the possibilities for enhancing supply chain efficiency are limitless.

Companies like Siemens, Microsoft, General Electric, and DHL are already demonstrating the significant benefits of IoT-ERP integration. As this trend continues, businesses that adopt these technologies early will gain a competitive edge, enhancing their agility, sustainability, and overall operational efficiency.

With the constant evolution of these technologies, it can be expected that even more innovative solutions that will drive the future of supply chain management. IoT and ERP integration is no longer a luxury; it is becoming a necessity for companies seeking to stay ahead in an increasingly competitive global market.

About the Author

Sukanya Dey is a passionate and insightful writer with over three years of experience, she excels in providing clients with in-depth research and valuable insights, helping them navigate complex business challenges. She has a keen interest in various industries, including Retail and Consumer, Healthcare, Manufacturing, Automotive, and ICT & Media. Sukanya strives to offer fresh perspectives and innovative solutions through her comprehensive research. She finds immense joy in weaving her thoughts and ideas into captivating articles and blogs, where her passion for literature and art shines through. In her free time, she enjoys reading books, cooking, filming, often drawing inspiration from these activities for her creative writing endeavors. The author can be reached at [email protected]

Sukanya Dey is a passionate and insightful writer with over three years of experience, she excels in providing clients with in-depth research and valuable insights, helping them navigate complex business challenges. She has a keen interest in various industries, including Retail and Consumer, Healthcare, Manufacturing, Automotive, and ICT & Media. Sukanya strives to offer fresh perspectives and innovative solutions through her comprehensive research. She finds immense joy in weaving her thoughts and ideas into captivating articles and blogs, where her passion for literature and art shines through. In her free time, she enjoys reading books, cooking, filming, often drawing inspiration from these activities for her creative writing endeavors. The author can be reached at [email protected]

Add Comment

Related Blogs

How IBM Drives Market Leadership with $61.86 Bn in Revenue

Next Move Strategy Consulting forecasts a substantial rise in the robot software...

What’s Driving BNPL Growth? Top Giants in Payment Industry

According to the Next Move Strategy Consulting analysis, the global buy now pay...

How Eye Tracking is Revolutionizing Industries

Introduction The eye tracking industry is thriving due to increased research...