Green Innovation: Environmental Benefits Of Advanced Phase Change Materials

17-Sep-2024

Introduction

Advanced phase change materials (PCMs) are specialized substances capable of undergoing reversible phase transitions, often from solid to liquid, absorbing or releasing substantial latent heat. These materials find application in diverse industries, providing efficient solutions for thermal energy storage, temperature regulation, and enhanced energy management systems, playing a major role in shaping the future of energy efficiency. In this blog, we will delve into the potential of these cutting-edge materials, exploring their applications, innovations, and the transformative impact they are set to have on the sustainable utilization of energy resources.

Integration with Smart Building Technologies

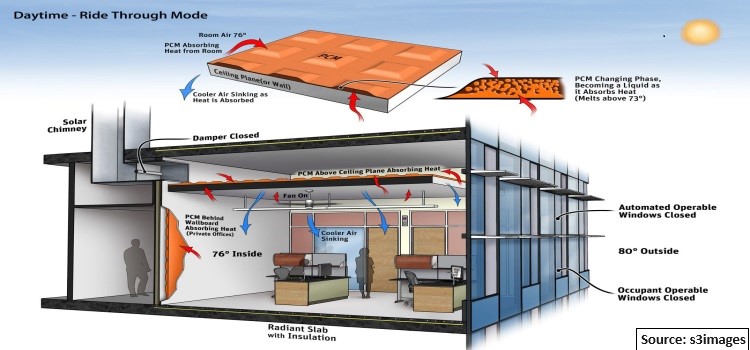

The integration of advanced phase change materials (PCMs) into construction industry stands as a transformative advancement, revolutionizing the landscape of building efficiency. The versatility of advanced PCMs extends their application across various sectors of the construction industry.

These materials find utility in diverse building components, such as walls, roofs, and floors, providing architects and engineers with flexibility in design while optimizing energy efficiency by eliminating the dependency on energy-intensive HVAC (Heating, Ventilation, and Air Conditioning) systems.

These innovative materials serve as thermal batteries, dynamically absorbing and releasing heat during phase transitions, particularly from solid to liquid and vice versa. By absorbing excess heat during warmer periods and releasing it when temperatures drop, these materials help maintain optimal indoor conditions, significantly reducing the reliance on traditional heating and cooling methods.

This not only enhances the comfort and well-being of building occupants but also results in substantial energy savings. As urbanization continues to accelerate globally, the demand for energy-efficient and environmentally conscious buildings becomes increasingly popular.

In essence, the adoption of advanced phase change materials in construction is a multifaceted solution, addressing the growing imperative for energy efficiency, occupant comfort, and sustainable building practices in the face of increasing urbanization and environmental concerns.

Biodegradable Phase Change Materials

Biodegradable phase change materials (PCMs), derived from renewable resources such as bio-based polymers or natural waxes, represent a notable trend in the industry. This shift towards developing phase change materials that are not only effective in their thermal energy storage properties but are also environmentally friendly throughout their lifecycle highlights the increasing emphasis on sustainable solutions that contribute to a reduction in ecological impact. By utilizing bio-based polymers or natural waxes sourced from renewable materials, these biodegradable PCMs offer a more sustainable alternative to traditional non-biodegradable counterparts.

As industries and consumers alike prioritize sustainability, the development and utilization of biodegradable PCMs provide a tangible solution to enhance the overall ecological profile of thermal energy storage systems. The emergence of biodegradable PCMs derived from renewable resources reflects a positive step toward fostering environmental responsibility and sustainability, catering to the increasing demand for eco-conscious solutions in diverse sectors.

Nano-Enhanced PCMs

The incorporation of nanomaterials, such as carbon nanotubes or graphene not only enhance thermal conductivity but also offers opportunities to engineer PCMs with tailored properties, including improved mechanical strength and stability. Nanomaterials are renowned for their exceptional thermal conductivity, making them ideal candidates for improving the heat transfer capabilities of PCMs.

The introduction of carbon nanotubes or graphene into PCMs creates a network of highly efficient thermal pathways. This enables more rapid and efficient heat transfer during the phase transition process, significantly elevating the overall thermal conductivity of the material. As a result, the thermal efficiency of PCMs is greatly augmented, making them more effective in absorbing, storing, and releasing thermal energy.

Beyond improved thermal conductivity, the integration of nanomaterials provides an innovative approach to tailor the properties of PCMs, such as enhancing the mechanical strength and stability of PCMs. This not only ensures the structural integrity of the material but also extends its applicability to diverse industrial scenarios with varying mechanical stresses.

Expanded Applications in Energy Storage

The growing focus towards of advanced energy storage solutions is paving the way for the development of hybrid systems that seamlessly integrate phase change materials (PCMs) with conventional energy storage technologies including batteries or supercapacitors.

This innovative approach aims to create synergistic energy storage solutions that capitalize on the strengths of each component, ultimately enhancing the overall reliability and stability of energy storage systems.

Renewable energy sources, such as solar and wind power, exhibit fluctuations in energy production due to factors such as weather conditions and time of day. The integration of PCMs into hybrid energy storage systems adds a dynamic layer to the storage process, introducing an element of thermal energy management to the storage equation.

In hybrid systems, PCMs complement traditional energy storage devices by absorbing excess energy during peak production periods and releasing it when energy demand is high or during periods of low renewable energy production. This strategic combination effectively addresses the intermittency and variability inherent in renewable energy sources, providing a more consistent and stable energy output.

Moreover, the integration of PCMs brings an added layer of flexibility to energy storage systems. The ability to store energy in the form of both electrical and thermal energy allows for optimized utilization based on real-time energy demands. This versatility contributes to the overall efficiency of the energy storage system, ensuring a more reliable and stable energy supply.

By eliminating the challenges associated with renewable energy intermittency, these advanced storage systems play a pivotal role in supporting the widespread adoption of clean and green energy sources. The combination of PCMs with batteries or supercapacitors represents a forward-looking approach that holds promise for addressing the evolving needs of the modern energy landscape.

Innovations in Microencapsulation

The utilization of microencapsulation techniques, such as spray drying or fluidized bed coating, in encapsulating phase change materials (PCMs) represents a significant advancement with wide-ranging applications. This innovative approach involves enveloping PCMs within tiny capsules, ensuring enhanced stability, preventing PCM leakage, and enabling controlled release. The application of microencapsulation extends across diverse industries, including textiles, healthcare, and even the food industry.

The integration of microencapsulated phase change materials (PCMs) in textiles, healthcare, and food industry among others has a transformative impact on both comfort and functionality. Materials embedded with these microcapsules can dynamically respond to changes in environmental temperature, absorbing and storing excess heat in warmer conditions to provide a cooling effect, safe transportation of medicines & vaccines, and extending the shelf life of perishable goods and maintaining optimal storage conditions to prevent fluctuations that could compromise the quality of sensitive items, promising advancements in comfort, functionality, and sustainability across diverse industries.

Advancements in Eutectic PCMs

Growing research in the development of Eutectic phase change materials (PCMs) that maintains a constant temperature during phase transitions, presenting a notable advantage in achieving precise thermal control is anticipated to play a significant role in the future of thermal control. These specialized PCM blends are engineered to undergo phase transitions at specific eutectic points, where the mixture of components displays a single, sharply defined melting and freezing temperature.

This characteristic ensures that eutectic PCMs undergo phase changes without experiencing temperature fluctuations, making them exceptionally well-suited for applications requiring accurate and stable thermal management. The customization of eutectic PCM blends allows researchers and engineers to design materials with phase change temperatures precisely tailored to the requirements of different industries.

For instance, in electronics cooling applications, eutectic PCMs can be formulated to match the specific temperature thresholds at which optimal heat dissipation is achieved. In building and construction, these materials can be customized to regulate indoor temperatures effectively, ensuring energy-efficient heating and cooling.

The advantage of maintaining a constant temperature during phase transitions positions eutectic PCMs as key contributors to advancements in thermal regulation across various sectors. Industries such as automotive, textiles, and energy storage benefit from the precision and stability offered by eutectic PCM blends. As technological innovations continue to drive material science, the tailored capabilities of eutectic PCMs open up new possibilities for achieving precise and reliable thermal control in a wide range of applications.

Conclusion

The advancements in Advanced Phase Change Materials (PCMs) are poised to revolutionize the landscape of energy efficiency and play a pivotal role in reducing global carbon emissions in the future. The innovative features of these materials, such as improved thermal properties, higher energy storage capacities, and diverse applications across industries, position them as key players in sustainable solutions. As the world increasingly focuses on environmental responsibility and seeks energy-efficient alternatives, the application of advanced PCMs is anticipated to change the dynamics of how we approach thermal management, contributing significantly to a greener and more sustainable future.

About the Author

Arjun Chetry is an accomplished researcher and writer with a history of more than three years of conducting thorough research. With a professional background as a research analyst, he has a keen eye for analyzing industry trends and understanding consumer behavior. His dedication to exploring diverse subjects and conducting in-depth analyses has equipped him with a deep understanding of research intricacies. He remains committed to staying up-to-date with the latest market trends and recognizing their impact on business and society. His well-rounded interests and experiences contribute to his ability to offer insights and perspectives on various topics. The author can be reached at info@nextmsc.com

Arjun Chetry is an accomplished researcher and writer with a history of more than three years of conducting thorough research. With a professional background as a research analyst, he has a keen eye for analyzing industry trends and understanding consumer behavior. His dedication to exploring diverse subjects and conducting in-depth analyses has equipped him with a deep understanding of research intricacies. He remains committed to staying up-to-date with the latest market trends and recognizing their impact on business and society. His well-rounded interests and experiences contribute to his ability to offer insights and perspectives on various topics. The author can be reached at info@nextmsc.com

Add Comment

Related Blogs

Industry Giants Securing 70 percentage of the Cold Pipe Insulation Market – What Sets Them Apart

Next Move Strategy Consulting forecasts a notable upsurge in...

Norsk Hydro Asa, Leading the Aluminium Sector With Around 28 Percentage Share – Here is Why

The aluminium market is expected to see a remarkable gr...

Exploring Closed Cell Crosslinked Foams: Advancements in Aerospace Applications

Introduction: Closed cell crosslinked foams have emerged as...