Flsmidth, Leading the ATLS Industry with Around 28% – Know the Reason Why

07-Oct-2024

According to the NMSC, the automated truck/trailer loading system (ATLS) market was valued at USD 642.3 million in 2023 and is anticipated to nearly double, reaching USD 1.12 billion by 2030. This substantial growth is largely driven by the increasing adoption of automated solutions within warehouses and the broader global logistics sector. As companies seek to enhance efficiency, reduce operational costs, and improve safety, the demand for advanced loading systems is surging. Automated systems streamline the loading and unloading processes, reduce manual labor, and minimize human error, contributing to faster and more reliable logistics operations. The integration of these technologies is transforming traditional warehousing and logistics practices, driving significant advancements and expansion within the ATLS market.

AUTOMATED TRUCK/TRAILER LOADING SYSTEM (ATLS) MARKET OVERVIEW

The ATLS market is experiencing significant growth as businesses seek to enhance efficiency and accuracy in their logistics and supply chain operations. ATLS solutions utilize a range of advanced technologies, including robotics, artificial intelligence, and sensor systems, to automate the loading and unloading of goods from trucks and trailers. This automation helps to reduce manual labor, minimize human error, and accelerate cargo handling processes, which is crucial for meeting the increasing demands of e-commerce and global trade. The adoption of ATLS is driven by the need for cost savings, improved safety, and higher operational efficiency in logistics and warehousing. Key industry players are continuously innovating, developing systems that integrate seamlessly with existing warehouse management systems and offer real-time tracking and optimization capabilities. As industries increasingly prioritize operational agility and cost-effectiveness, the ATLS market is poised for continued expansion by offering transformative benefits for supply chain management and distribution networks.

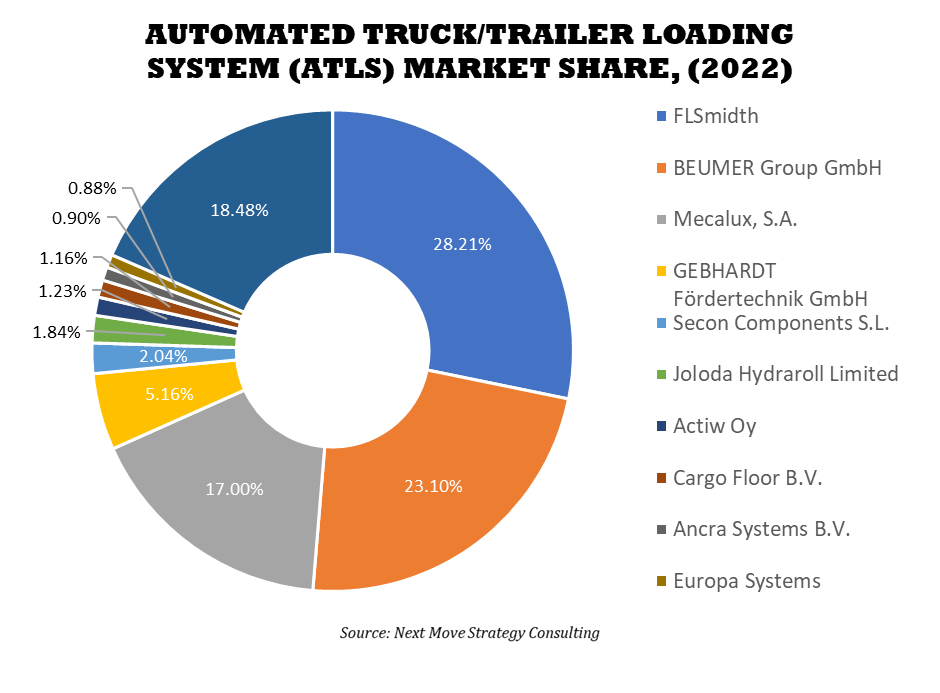

The prominent players operating in ATLS industry includes FLSmidth, BEUMER Group GmbH, Mecalux, S.A., GEBHARDT Fördertechnik GmbH, Secon Components S.L., Joloda Hydraroll Limited, Actiw Oy, Cargo Floor B.V., Ancra Systems B.V., and Europa Systems each contributing significantly to the industry's evolution.

For the latest market share analysis and in-depth ATLS industry insights, you can reach out to us at: https://www.nextmsc.com/automated-truck-trailer-loading-system-atls-market/request-sample

HIGHLIGHTS OF FLSMIDTH & CO. A/S

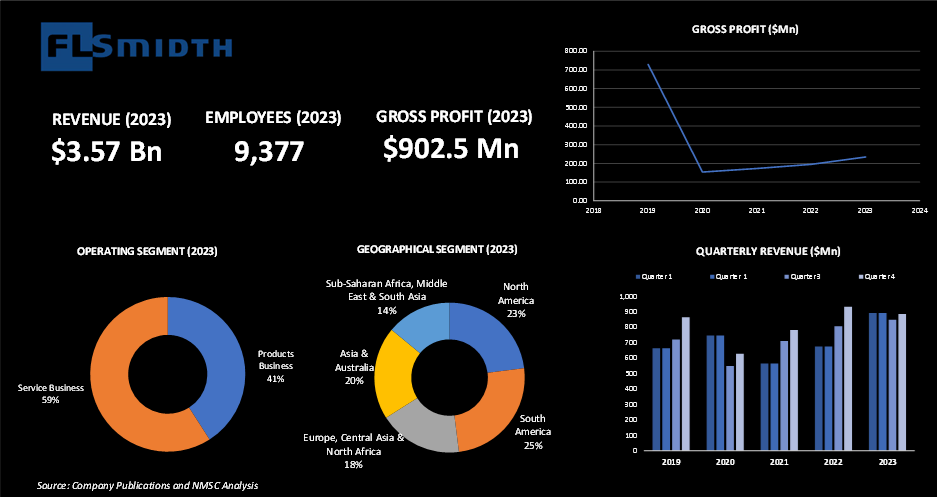

FLSmidth, headquartered in Copenhagen, Denmark, stands as a global leader in engineering solutions for the mining and cement industries, and has increasingly positioned itself as a key player in the automated truck/trailer loading system (ATLS) market. The company's financial performance in 2023 marked by significant growth, with revenue reaching USD 3.57 billion, an increase from USD 3.13 billion in 2022. This growth was accompanied by a rise in gross profit, which grew from USD 728 million in 2022 to USD 902.5 million in 2023, underscoring FLSmidth's strong operational execution and expanding market presence.

FLSmidth operates through two primary business segments, the products business, which generated USD 1.46 billion in revenue, and the service business, contributing USD 2.11 billion in 2023. This balanced revenue stream highlights the company's diversified approach to meeting the needs of its global clientele, offering both cutting-edge products and comprehensive service solutions that ensure the longevity and efficiency of their operations.

Geographically, FLSmidth's operations are well-diversified, with substantial revenue contributions from key regions around the world. South America led the way with USD 903.52 million, followed by North America with USD 820.7 million, Asia & Australia with USD 698.4 million, Europe, Central Asia & North Africa with USD 649.5 million, and Sub-Saharan Africa, Middle East & South Asia contributing USD 501.7 million. This geographic spread not only mitigates risk but also allows FLSmidth to leverage growth opportunities across various markets, particularly in regions with high demand for industrial automation and advanced material handling solutions.

The company also places a strong emphasis on research and development (R&D), with R&D expenditures increasing to USD 529.5 million in 2023, up from USD 440.9 million in 2022 and USD 422.5 million in 2021. This continuous investment in R&D reflects FLSmidth's commitment to innovation and its focus on developing advanced technologies that drive efficiency, productivity, and sustainability in the mining and cement industries, as well as in the emerging ATLS market.

In addition to organic growth, FLSmidth pursued strategic acquisitions to enhance its capabilities and expand its market share. In August 2022, the company acquired Mining Technologies, a leading supplier of solutions for mining systems, material handling, and mineral processing. This acquisition positioned FLSmidth as a dominant player in the global mining technology and services sector, offering comprehensive solutions from pit-to-plant with a strong emphasis on sustainability and productivity. The company further expanded its portfolio in June 2023 by acquiring Morse Rubber, an American company specializing in advanced molding capabilities for rubber and composite mill liners, screen media, and various rubber and rubber ceramic wear components. This acquisition supports FLSmidth's CORE'26 strategy, which focuses on enhancing its offerings in the mining sector through innovation and strategic growth.

FLSmidth's commitment to advancing the ATLS market is evident in its continuous efforts to develop and integrate state-of-the-art technologies that meet the evolving demands of the industry. The company's robust financial performance, strategic acquisitions, and sustained investment in R&D position it as a key player in driving the future of automated material handling systems, offering solutions that enhance operational efficiency, reduce costs, and contribute to the sustainability goals of its global customers. With a workforce of 9,377 employees, FLSmidth remains dedicated to delivering high-quality, innovative solutions that address the challenges and opportunities of modern industrial operations.

HIGHLIGHTS OF BEUMER GROUP GMBH & CO.

BEUMER Group GmbH founded in 1935 by Bernhard Beumer, is one of the prominent global providers of intralogistics solutions, renowned for its advanced material handling systems, especially in the ATLS market. The company’s ATLS solutions are designed to boost efficiency and safety in logistics operations across industries such as warehousing, parcel handling, and manufacturing. BEUMER Group emphasizes automation in its systems, which integrate seamlessly into existing workflows to optimize the loading process, reduce manual labor, and lower operational costs.

The company offers a range of sophisticated ATLS products, including the BEUMER AutoLoad, which automates the loading process by efficiently distributing and securing goods within trucks or trailers. Another key product, the BEUMER Stretch Hood, provides automated stretch wrapping to safeguard goods during transport. Additionally, BEUMER’s Palletizer and Sorter systems are crucial components of their ATLS solutions, enhancing the automated handling and sorting of palletized goods. These products are engineered for high performance, reliability, and flexibility, aimed at improving loading accuracy and overall logistics efficiency.

In July 2024, BEUMER Group announced a significant investment of over USD 23.88 million to establish a production site in Reliance MET City, Jhajjar, India. This investment represents a pivotal expansion for the company, making it the first German firm to set up production in this newly developed economic zone, which is designed to enhance infrastructure and business operations.

HIGHLIGHTS OF SECON COMPONENTS S.L.

Secon Components S.L., based in Barcelona, Spain, is a key player in the ATLS industry, recognized for its commitment to delivering high-quality, precision-engineered components and solutions. With a well-established global presence, the company offers an extensive product range that includes custom precision-machined parts, structural assemblies, and sophisticated electronic and mechanical systems.

Secon Components S.L.'s product portfolio is comprehensive, featuring advanced conveyor systems such as chain, slat, belt, skate, and roller track systems, all designed to efficiently handle the transportation of heavy loads, pallets, containers, boxes, and packages. In addition, the company provides automated guided vehicles (AGVs) to facilitate material transportation within warehouses and loading docks, significantly enhancing automation and reducing the reliance on manual labor.

The company also specializes in cutting-edge control systems that ensure precise management of loading and unloading processes. Their ability to customize solutions allows seamless integration with existing infrastructure, making their ATLS offerings adaptable to a variety of operational environments. Secon Components S.L.'s solutions are specifically tailored to meet the diverse needs of industries such as retail, industrial, medical, automotive, and textile sectors. By focusing on improving operational efficiency, enhancing safety, and lowering labor costs, Secon Components S.L. plays a crucial role in optimizing logistics and supply chain management processes.

HIGHLIGHTS OF GEBHARDT FÖRDERTECHNIK GMBH

Gebhardt Fördertechnik GmbH, headquartered in Sinsheim, Germany, was founded in 1952 and is one of the prominent players in the material handling and intralogistics industry. The company is renowned for its specialization in ATLS, where it delivers innovative solutions designed to boost efficiency, safety, and productivity in logistics operations. Their extensive product range includes modular conveyance systems, sophisticated warehouse technology, and efficient handling systems for a variety of load carriers.

Gebhardt also offers low-noise sorting technology, ergonomic workstations for order picking, automated guided vehicles (AGVs) for autonomous transportation, and the GEBHARDT ConVer Goods Lift for multi-floor connectivity. Additionally, they provide advanced software solutions for inventory management and tailor their offerings to meet the unique requirements of their customers. This comprehensive approach has firmly established Gebhardt as a market leader in the ATLS industry, catering to diverse sectors with cutting-edge technology and customized solutions.

With a legacy of innovation and a commitment to advancing logistics technology, Gebhardt Fördertechnik GmbH continues to set the standard in the ATLS industry. Their broad spectrum of products and tailored solutions not only address the current needs of various industries but also anticipate future trends, ensuring their clients remain competitive and efficient in an evolving market.

HIGHLIGHTS OF MECALUX, S.A.

Mecalux, S.A., founded in 1966 by José Hernández, is one of the global players in the ATLS market, with its headquarters in Spain. Renowned for its expertise in logistics and automation, Mecalux offers a diverse range of solutions designed to revolutionize warehouse operations. Their product portfolio includes cutting-edge automated loading and unloading systems, conveyor systems, and high-performance palletizers, all engineered to enhance efficiency, accuracy, and speed in loading processes.

In October 2023, Mecalux made significant strides in innovation by launching an advanced robotic order picking system that integrates artificial intelligence (AI) and Siemens' cutting-edge technology. This system is designed to further optimize warehouse operations by automating the order picking process, which improves both accuracy and efficiency. The integration of AI enables the system to learn and adapt to varying order patterns, while Siemens' technology ensures seamless and reliable performance.

Mecalux's commitment to innovation extends beyond their ATLS solutions. Their systems are built to maximize space utilization, reduce labor costs, and streamline logistics processes. With a focus on technological advancement and operational excellence, Mecalux continues to be a key player in transforming the logistics and supply chain landscape, offering solutions that meet the evolving needs of modern industries.

Have questions? Inquire before purchasing the full report: https://www.nextmsc.com/automated-truck-trailer-loading-system-atls-market/inquire-before-buying

SUMMARY OF AUTOMATED TRUCK/TRAILER LOADING SYSTEMS (ATLS) INDUSTRY

The automated truck/trailer loading system (ATLS) market is rapidly growing, fueled by advancements in robotics, AI, and sensors. Key players like FLSmidth, BEUMER Group, Mecalux, GEBHARDT Fördertechnik, and Secon Components are driving this expansion with innovative solutions that enhance efficiency, reduce labor, and improve safety in logistics. This growth reflects the industry's shift towards more automated and effective loading and unloading processes. As global logistics and e-commerce demands surge, ATLS technologies are becoming crucial for optimizing supply chain operations and ensuring faster, more reliable deliveries.

ABOUT THE AUTHOR

Supratim Bhowmick is a passionate and highly enthusiastic researcher with over two and a half years of experience. He is dedicated to assisting clients in overcoming challenging business obstacles by providing actionable insights through exhaustive research. Supratim has a keen interest in writing articles and blogs, along with content writing. He consistently endeavors to deliver valuable perspectives in these areas. In addition to his research work, Supratim enjoys traveling and engaging in various sports during his leisure time. The author can be reached at info@nextmsc.com

Supratim Bhowmick is a passionate and highly enthusiastic researcher with over two and a half years of experience. He is dedicated to assisting clients in overcoming challenging business obstacles by providing actionable insights through exhaustive research. Supratim has a keen interest in writing articles and blogs, along with content writing. He consistently endeavors to deliver valuable perspectives in these areas. In addition to his research work, Supratim enjoys traveling and engaging in various sports during his leisure time. The author can be reached at info@nextmsc.com

Add Comment

Related Blogs

Powerhouses of Intralogistics: How Honeywell and KION are Revolutionizing the Future of Automation

The intralogistics sector is set to experience substantial g...

What makes Honeywell and ABB the Giants of the DCS Market: Find Out Now

According to Next Move Strategy Consulting analysis the glob...