Automated Truck/Trailer Loading System (ATLS) Market by Type (Ground-Based and Overhead), by Automation (Semi-Automatic and Fully Automatic), by Load Type (Fluid Loads, Containers, Totes, Pallets, and Wheeled Carts/Cages), by Truck/Trailer Type (Non-Modified and Modified), by Loading System (Chain Conveyor System, Slat Conveyor System, Belt Conveyor System, Skate Conveyor System, Roller Track System, Loading Plate System, and Others), and by Industry Vertical (Aviation, Cement, Paper, FMCG, Post & Parcel, Automotive, Textile, and Pharmaceutical) – Global Opportunity Analysis and Industry Forecast, 2023–2030

Industry: Construction & Manufacturing | Publish Date: 18-Sep-2023 | No of Pages: 334 | No. of Tables: 259 | No. of Figures: 241 | Format: PDF | Report Code : N/A

Market Overview

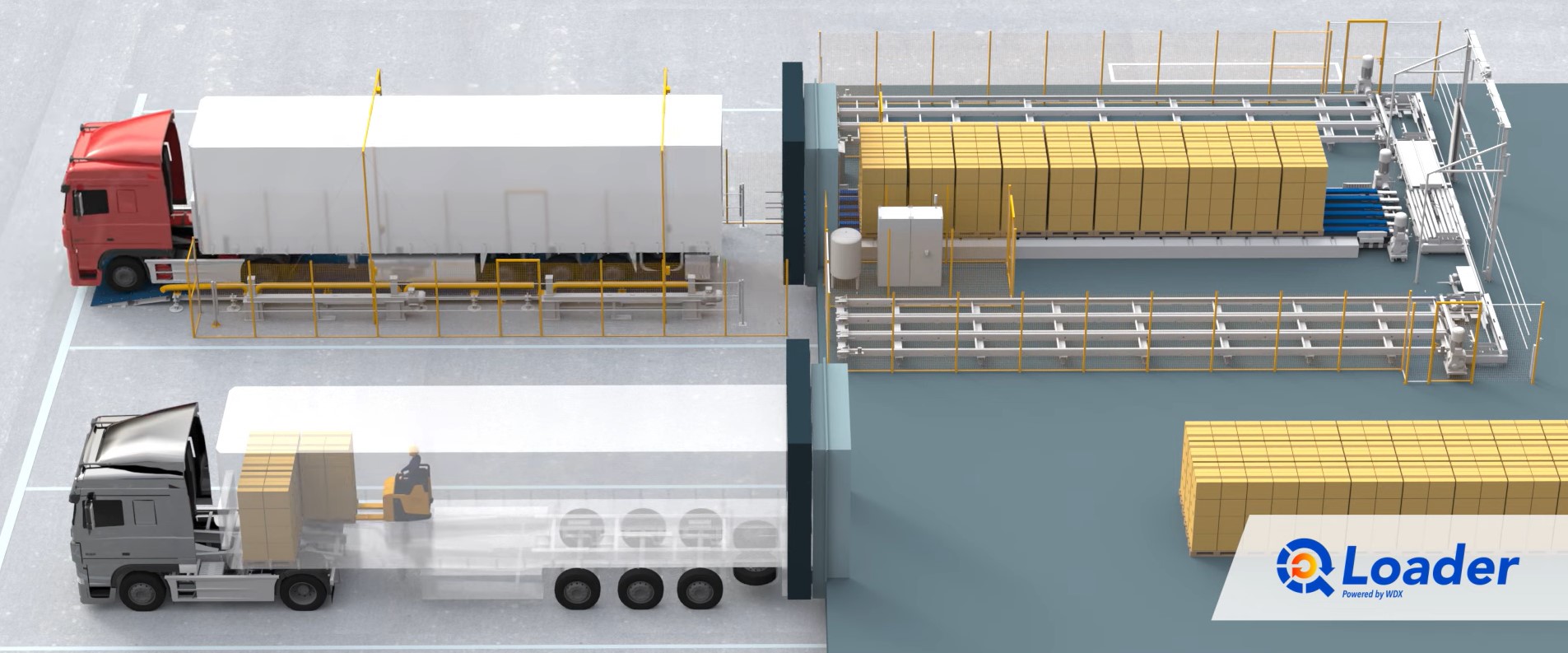

The Automated Truck/Trailer Loading System Market size was valued at USD 553.9 million in 2022, and is predicted to reach USD 1168 million by 2030, with a CAGR of 8.9% from 2023 to 2030. An automated truck/trailer loading system (ATLS) is a technology-driven material handling solution designed to automate the tasks associated with loading and unloading trucks and trailers. Typically, ATLS comprises a conveyor system, a loading dock, and a control system. The conveyor system transports pallets or containers to the loading dock, where the control system handles the loading or unloading process. The primary objective of ATLS is to streamline and enhance logistics and supply chain operations by automating the manual tasks involved in handling goods during loading and unloading. This automation improves efficiency, safety, and productivity within warehouses and distribution center environments.

ATLS employs a combination of mechanical, conveyor, sensor, and control technologies to efficiently and accurately manage various types of cargo, including individual boxes, containers, pallets, and bulk goods. These systems are seamlessly integrated into loading docks, warehouses, and distribution centers. They considerably contribute to operational efficiency gains, increased throughput, and enhanced safety by reducing the need for manual labor in the loading process. These solutions can be tailored to fulfil the needs of specific industries, cargo varieties, and existing infrastructure, ensuring adaptability and efficiency improvements in diverse logistical scenarios.

The growing adoption of automation in warehouses boosts the automated truck/trailer loading system market

The widespread implementation of automated solutions in warehouses and the global logistics sector is acting as a catalyst for the growth and advancement of the ATLS industry. This adoption aligns seamlessly with ATLS technology as companies seek comprehensive automation within their logistics and supply chain activities. The integration of ATLS with existing automation infrastructure, such as conveyor systems and robotic material handling, significantly enhances operational efficiency. According to data from the McKinsey Global Institute, countries with high levels of automation adoption include Japan (55.7%), the Czech Republic (52.1%), Kenya (51.9%), and Mexico (51.8%). This underscores a favorable environment for the adoption of robotics and automation, including ATLS, in the coming years.

The rising global labor costs propel the ATLS market growth

The worldwide increase in labor costs fuels the adoption of ATLS in various industries. According to the European Statistics, during the first quarter of 2023, there was a 5.0% increase in hourly labor costs in the Eurozone (a member of 20 countries in the European Union) and a 5.3% rise in the European Union (EU) in comparison to the same quarter of the previous year. Companies are searching for cost-effective and efficient solutions as labor expenses rise, especially in the labor-intensive sectors such as manufacturing and logistics. Finding and retaining a workforce capable of tasks such as loading and unloading trucks is getting tougher. In response, ATLS has become a strong solution as these systems reduce the need for human labor and deliver consistent and reliable performance. They work continuously without breaks, improving efficiency and cost savings. This makes them an attractive choice for industries looking to improve operations while managing high labor expenses.

High initial upfront investments restraint the market growth

Many organizations face significant hurdles while considering ATLS due to the substantial upfront expenses involved. This factor restrains the growth of the market. These initial costs encompass purchasing technology, infrastructure investments, covering the customization and integration expenses, providing the workforce training, seeking the consulting services, and considering the scalability.

The integration of advanced technologies creates opportunities for the market

The integration of artificial intelligence (AI), the Internet of Things (IoT), and predictive maintenance into ATLS is expected to create ample growth opportunities for the market in the future. AI optimizes loading and unloading in real time using IoT data, boosting overall efficiency. Predictive Maintenance reduces downtime and unexpected repair costs. It also enhances safety through IoT monitoring and AI-driven risk identification, lowering liability expenses. This integration generates valuable data insights for informed decision-making, offers customization and scalability, and appeals to industries seeking modern solutions. These factors, in turn, create opportunities for the market growth.

North America dominates the automated truck/trailer loading system market

The ATLS market in North America is experiencing significant growth, due to the pursuit of businesses to enhance efficiency, supply chain optimization, and reduced labor expenses. Companies are increasingly turning to automated trailer loading solutions to improve load accuracy, use available space in a better manner, and shorten loading times. This trend creates a significant opportunity for technology providers and manufacturers to offer customized ATLS solutions to a wide range of industries. With the growing emphasis on seamless supply chain operations, the ATLS market in North America, particularly the U.S., is poised for further expansion.

Also, the well-established food and beverage industry in countries such as Canada and the U.S. significantly boosts the market growth. This industry is one of the key sectors that extensively utilize ATLS technology. The use of ATLS in the food and beverage sector helps streamline loading and unloading processes, ensuring efficient and timely distribution of products. According to Unifor, the food and beverage sector is Canada's second-largest manufacturing industry, with nearly USD 118 billion in sales in 2019. It is a major contributor to the national economy, generating USD 34.5 billion in GDP in 2021, or almost 2% of the total.

Asia-Pacific is expected to show steady growth in the automated truck/trailer loading system market

Asia-Pacific is expected to witness an increased demand for ATLS in the coming years, driven by factors such as the substantial number of warehouses and the rapid adoption of warehouse automation. According to the report published by the Interact Analysis in 2022, approximately 45% of the total warehouse building stock is situated in China or the U.S., with China boasting the largest number of warehouses. With more than 18,310 warehouses and storage facilities, China presents a substantial growth potential for the ATLS industry. The presence of many warehouses across the region, driven by increasing trade and e-commerce activities, has created a strong demand for efficient loading and unloading solutions. This, in turn, boosts the market growth.

In addition, the rising initiatives from governments aimed at promoting automation and robotics in countries, such as Australia and China, are further propelling the growth of the market. According to a report published by the Australian Department of Industry, Science, and Resources, the country is adopting the National Robotics Strategy, an initiative for the promotion of the responsible adoption and production of automation and robotics technologies. Governments recognize the potential benefits of automation in various industries, including logistics and transportation. These initiatives include incentives, grants, and policies encouraging businesses to adopt automation technologies such as ATLS. As a result, companies are more inclined to invest in these systems to enhance efficiency, reduce costs, and remain competitive.

Competitive Landscape

Several market players operating in the automated truck/trailer loading system market include FLSmidth & Co. A/S, BEUMER Group GmbH, Mecalux, S.A., GEBHARDT Fördertechnik GmbH, Secon Components S.L., Joloda Hydraroll Limited, Actiw OY, Cargo Floor B.V., Ancra Systems B.V., Europa Systems, and others. These market players are adopting product launch and partnership strategies across various regions to maintain dominance in the ATLS market.

For instance, in December 2022, Actiw Ltd. partnered with New Caledonia to advance efficiency in the battery chemical industry, securing an order for two LoadMatic systems. These systems, featuring integrated bag handling and infeed solutions, are set to bolster operational processes for Prony Resources and contribute to streamlined cargo management.

Moreover, in August 2022, MECALUX, a provider of intralogistics solutions, showcased its cutting-edge warehouse automation technologies at the IMHX 2022 fair. The company highlighted its commitment to innovation in the industry. The event served as a platform for MECALUX to demonstrate its latest advancements in warehouse management systems and automated material handling solutions to a global audience.

Furthermore, in July 2022, Beumer Group launched the latest generation line sorter and pouch systems to cater to the evolving demands of the logistics industry. These innovative solutions enhance sorting and packaging efficiency for various sectors, offering advanced automation and adaptability.

KEY MARKET SEGMENTS

By Type

-

Ground-Based

-

Overhead

By Automation

-

Semi-Automatic

-

Fully Automatic

By Load Type

-

Fluid Loads

-

Containers

-

Totes

-

Pallets

-

Wheeled Carts/Cages

By Truck/Trailer Type

-

Non-modified

-

Modified

By Loading System

-

Chain Conveyor System

-

Slat Conveyor System

-

Belt Conveyor System

-

Skate Conveyor System

-

Roller Track System

-

Loading Plate System

-

Others

By Industry Vertical

-

Aviation

-

Cement

-

Paper

-

FMCG

-

Post & Parcel

-

Automotive

-

Textile

-

Pharmaceutical

By Region

-

North America

-

The U.S.

-

Canada

-

Mexico

-

-

Europe

-

The U.K.

-

Germany

-

France

-

Italy

-

Spain

-

Denmark

-

Netherlands

-

Finland

-

Sweden

-

Norway

-

Russia

-

Rest of Europe

-

-

Asia-Pacific

-

China

-

Japan

-

India

-

South Korea

-

Australia

-

Indonesia

-

Singapore

-

Taiwan

-

Thailand

-

Rest of Asia-Pacific

-

-

Rest of the World (RoW)

-

Latin America

-

Middle East

-

Africa

-

REPORT SCOPE AND SEGMENTATION:

|

Parameters |

Details |

|

Market Size in 2022 |

USD 554 Million |

|

Revenue Forecast in 2030 |

USD 1168 Million |

|

Growth Rate |

CAGR of 8.9% from 2023 to 2030 |

|

Analysis Period |

2022–2030 |

|

Base Year Considered |

2022 |

|

Forecast Period |

2023–2030 |

|

Market Size Estimation |

Million (USD) |

|

Growth Factors |

Growing adoption automation in the warehouses Rising global labor costs |

|

Countries Covered |

28 |

|

Companies Profiled |

10 |

|

Market Share |

Available for 10 companies |

|

Customization Scope |

Free customization (equivalent up to 80 working hours of analysts) after purchase. Addition or alteration to country, regional, and segment scope. |

|

Pricing and Purchase Options |

Avail customized purchase options to meet your exact research needs. |

KEY PLAYERS :

-

FLSmidth & Co. A/S

-

BEUMER Group GmbH

-

Mecalux, S.A.

-

GEBHARDT Fordertechnik GmbH

-

Secon Components S.L.

-

Joloda Hydraroll Limited

-

Actiw OY

-

Cargo Floor B.V.

-

Ancra Systems B.V.

-

Europa Systems

Speak to Our Analyst

Speak to Our Analyst