Canada Intralogistics Market by Component (Hardware, Software, and Services), and by End User Industry (Logistics, Food & Beverages, Retail & E-commerce, Automotive, Chemicals, Pharmaceuticals, Airport, and Mining) – Opportunity Analysis and Industry Forecast 2023–2030

Industry: Construction & Manufacturing | Publish Date: 04-Dec-2023 | No of Pages: 75 | No. of Tables: 50 | No. of Figures: 21 | Format: PDF | Report Code : N/A

Market Definition

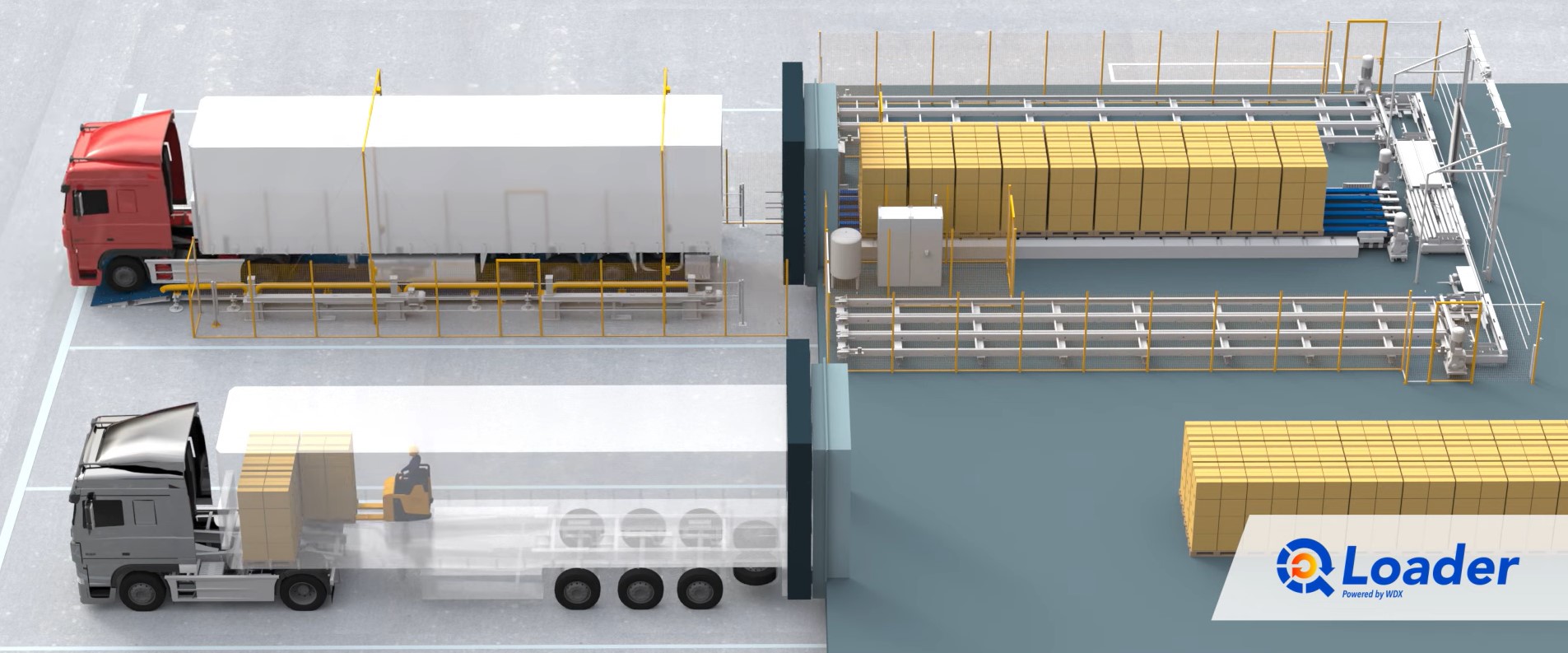

The Canada Intralogistics Market was valued at USD 2.03 billion in 2022, and is predicted to reach USD 5.34 billion by 2030, with a CAGR of 12.79% from 2023 to 2030. Intralogistics is a vital aspect of supply chain management, and its market is focused on the design, implementation, and maintenance of internal logistics systems. To maximise the flow of materials and effectively and economically meet the company's demands, it entails the movement, storage, and management of commodities within an organisation, such as a factory, warehouse, or distribution centre.

The intralogistics market involves the design, implementation, and maintenance of factory and warehouse systems and includes various industries such as manufacturing, retail, e-commerce, and healthcare. Material handling, inventory control, order fulfilment, and reverse logistics are some of the most frequent applications of intralogistics. The intralogistics industry is expanding as a result of the rising need for quick and effective delivery, rising demand for automation, and rising demand for sustainable and environmentally friendly solutions.

Canada's Bold Moves: Revolutionizing Industries Through Strategic Robotics Initiatives

The several initiatives taken by the government in Canada, further increase the adoption of robotics in the industries for applications such as product handling or sorting, in turn driving the growth of the market. For instance, in April 2022, the Canadian Government announced an investment of $780 million over the next five years to create a funding agency focused on innovation in science and technology, to offer strong programs in robotics and related fields, in turn producing a skilled workforce in the country.

Additionally, major investments are being made in Canada's intralogistics industry by international merchants like Walmart. For instance, Walmart Canada stated in March 2022 that it would spend more than $118 million to construct a new, cutting-edge sortable fulfilment facility in Alberta, Canada.

Canada's Surging Intralogistics Market Fueled by Automation and Robotics Dominance in Manufacturing

Canada's intralogistics market is experiencing robust growth, particularly in the realms of automation, warehouse management, and robotics. This surge is attributed to the substantial manufacturing presence in the country, notably in the automotive and aerospace sectors.

The dynamic expansion of these industries has become a driving force behind the flourishing intralogistics market in Canada. Key focal points include the integration of advanced automation, the widespread adoption of robotics, and the implementation of real-time tracking systems. This concerted effort reflects a commitment to enhancing efficiency and productivity within the Canadian manufacturing landscape.

High Installation Cost of Intralogistics Systems Can Gloom the Market Prospects

The high installation cost of intralogistics systems can be a significant barrier to adoption and can limit the market prospects for these systems. Intralogistics systems typically require significant investments in technology and infrastructure, including specialized equipment, software, and hardware, as well as the cost of installation and maintenance.

Some organisations, especially small and medium-sized enterprises (SMEs), which may have limited resources to invest in these technologies, may find this high upfront cost to be prohibitive. The scale and complexity of the operation, the level of customization needed, and the level of automation requested can all have an impact on how much intralogistics systems cost. As a result, some businesses may opt for less expensive and less efficient alternatives, which can limit the growth and adoption of intralogistics systems in the market.

Unlocking Opportunities: Introduction of Drones in the Intralogistics Industry to Create Future Market Prospects

The introduction of drones in intralogistics has the potential to create significant growth opportunities for businesses that rely on efficient supply chain operations. Drones, also known as unmanned aerial vehicles (UAVs), are being used in intralogistics to automate a range of tasks, including inventory management, order picking, and delivery.

Businesses may increase the accuracy and speed of their operations while cutting the time and expense of manual labour and transportation by utilising drone technology. Drones can also increase the flexibility and scalability of intralogistics, allowing businesses to quickly adjust to fluctuations in demand. Moreover, drones can improve efficiency and reduce the risk of accidents or injuries for workers who might otherwise need to use ladders or other equipment to access these areas.

In addition, drones can gather information on inventory levels, product quality, and other key metrics, providing businesses with valuable insights into their operations by using sensors and cameras. This data can be used to optimize processes, improve forecasting, and reduce waste, leading to cost savings and improved efficiency. All these above-mentioned factors are expected to create growth opportunities for the intralogistics market shortly.

Competitive Landscape

The Canada intralogistics industry includes several market players such as Daifuku Co. Ltd., Jungheinrich AG, Kion Group AG, Honeywell International Inc., Midea Group, Vanderlande Industries B.V., SSI Schaefer AG, KNAPP AG, Beumer Group Gmbh and Co. KG, and Autostore.

Key Benefits

-

The Canada intralogistics market report provides a quantitative analysis of the market and estimations throughout 2023-2030 that assist in identifying the prevailing market opportunities to capitalize on.

-

The study comprises a deep-dive analysis of the current and future Canada intralogistics market trends, depicting the prevalent investment pockets in the industry.

-

The information related to key drivers, restraints, and opportunities and their impact on the market is provided in the report.

-

The competitive analysis of the market players along with their market share in the Canadian intralogistics market.

-

The SWOT analysis and Porter’s Five Forces model are elaborated in the study.

-

Value chain analysis in the market study provides a clear picture of the stakeholders’ roles.

Canada Intralogistics Market Key Segments

By Component

-

Hardware

-

Automated Storage and Retrieval Systems (AS/RS)

-

Unit-Load AS/RS

-

Mini-Load AS/RS

-

Vertical Lift Modules (VLMs)

-

Carousel AS/RS

-

-

Industrial Robots

-

Mobile Robots

-

Automated Guided Vehicles (AGV)

-

Autonomous Mobile Robots (AMR)

-

-

Conveyor Systems

-

Sortation Systems

-

-

Software

-

Services

By End User Industry

-

Logistics

-

Food And Beverages

-

Retail And E-Commerce

-

Automotive

-

Chemicals

-

Pharmaceuticals

-

Airport

-

Mining

REPORT SCOPE AND SEGMENTATION:

|

Parameters |

Details |

|

Market Size in 2022 |

USD 2.03 Billion |

|

Revenue Forecast in 2030 |

USD 5.34 Billion |

|

Growth Rate |

CAGR of 12.79% from 2023 to 2030 |

|

Analysis Period |

2022–2030 |

|

Base Year Considered |

2022 |

|

Forecast Period |

2023–2030 |

|

Market Size Estimation |

Billion (USD) |

|

Growth Factors |

Automation and robotics dominance. Increasing government initiatives. |

|

Companies Profiled |

10 |

|

Market Share |

Available for 10 companies |

|

Customization Scope |

Free customization (equivalent up to 80 working hours of analysts) after purchase. Addition or alteration to country, regional, and segment scope. |

|

Pricing and Purchase Options |

Avail customized purchase options to meet your exact research needs. |

KEY PLAYERS

-

Daifuku Co. Ltd.

-

Jungheinrich AG

-

Kion Group AG

-

Honeywell International Inc.

-

Midea Group

-

Vanderlande Industries B.V.

-

SSI Schaefer AG

-

KNAPP AG

-

Beumer Group Gmbh and Co. KG

-

Autostore

Speak to Our Analyst

Speak to Our Analyst