Italy Intralogistics Market by Component (Hardware, Software, and Services), and by End User Industry (Logistics, Food & Beverages, Retail & E-commerce, Automotive, Chemicals, Pharmaceuticals, Airport, and Mining) – Opportunity Analysis and Industry Forecast 2023–2030

Industry: Construction & Manufacturing | Publish Date: 05-Dec-2023 | No of Pages: 74 | No. of Tables: 50 | No. of Figures: 21 | Format: PDF | Report Code : N/A

Market Definition

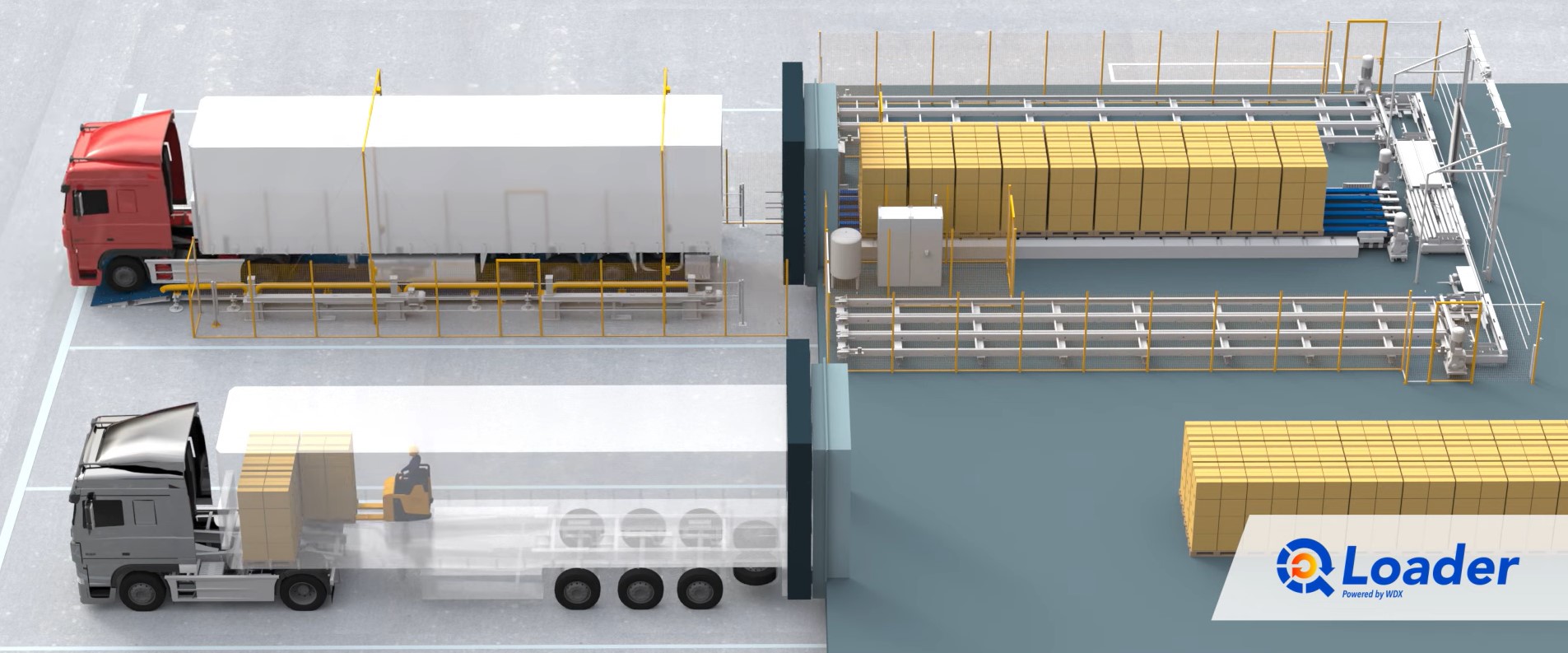

Italy Intralogistics Market was valued at USD 1.58 billion in 2022, and is predicted to reach USD 5.66 billion by 2030, with a CAGR of 17.1% from 2023 to 2030. Intralogistics is a vital aspect of supply chain management, and its market is focused on the design, implementation, and maintenance of internal logistics systems. In order to maximise the flow of materials and effectively and economically meet the company's demands, it entails the movement, storage, and management of commodities within an organisation, such as a factory, warehouse, or distribution centre.

The intralogistics market involves the design, implementation, and maintenance of factory and warehouse systems and includes various industries such as manufacturing, retail, e-commerce, and healthcare. Material handling, inventory control, order fulfilment, and reverse logistics are some of the most frequent applications of intralogistics. The intralogistics industry is expanding as a result of rising need for quick and effective delivery, rising demand for automation, and rising demand for sustainable and environmentally friendly solutions.

Italy's Industrial Mastery: Elevating Efficiency with Intralogistics Precision and Industry 4.0 Initiatives

Italy is one of the leading manufacturers in Europe. The international trade administration estimates that as of 2022, Italy would be the second-largest producer in Europe, with the biggest capacity in industries including machine tools, textiles, food items, automotive, and pharmaceuticals. Such industries widely use intralogistics solutions for repetitive tasks such as picking and packing, material handling, and pelletizing/depalletizing to increase efficiency and accuracy, leading to a more streamlined supply chain and reduced costs associated with manual labour.

Moreover, the government of Italy is taking several initiatives in the country to increase the popularity and adoption of industry 4.0 in the country. For instance, in March 2022, the Italian minister of economic development allotted a fund of 1.01 billion USD for investments in industry 4.0 in the country as a part of the National Recovery and Resilience Plan (PNRR). Industry 4.0 refers to a new phase in the industrial revolution that focuses heavily on interconnectivity, and automation.

It integrates the internet of things (IoT) or smart digital technology, machine learning, and big data with physical operations to create a better-connected ecosystem for companies that focus on supply chain management. To integrate these new technologies such as cloud computing and analytics, and AI and machine learning into their warehouse facilities, manufacturers in Italy are required to use robots, which in turn increases the adoption of AMRs, AGVs and industrial robots. These factors are driving the growth of the market.

Italy's Corporate Environment Adopts State-of-the-Art Intralogistics for Optimal Supply Chain Optimization

Italian companies are in the midst of a substantial technological transformation within their supply chains. They are embracing advanced intralogistics solutions, incorporating sophisticated software, leveraging data analytics, and deploying intelligent warehouse management systems. This collective endeavor transcends mere efficiency; it signifies a strategic advancement towards unmatched operational optimization.

As the business landscape in Italy undergoes evolution, this tech-driven transformation positions companies at the forefront of supply chain excellence. It heralds a future where precision seamlessly meets productivity, creating a harmonious and streamlined approach to operations.

High Installation Cost of Intralogistics Systems Can Gloom the Market Prospects

The high installation cost of intralogistics systems can be a significant barrier to adoption and can limit the market prospects for these systems. Intralogistics systems typically require significant investments in technology and infrastructure, including specialized equipment, software, and hardware, as well as the cost of installation and maintenance.

Some organisations, especially small and medium-sized enterprises (SMEs), which may have limited resources to invest in these technologies, may find this high upfront cost to be prohibitive. The scale and complexity of the operation, the level of customization needed, and the level of automation requested can all have an impact on how much intralogistics systems cost. As a result, some businesses may opt for less expensive and less efficient alternatives, which can limit the growth and adoption of intralogistics systems in the market.

Unlocking Opportunities: Introduction of Drones in Intralogistics Industry to Create Future Market Prospects

The introduction of drones in intralogistics has the potential to create significant growth opportunities for businesses that rely on efficient supply chain operations. Drones, also known as unmanned aerial vehicles (UAVs), are being used in intralogistics to automate a range of tasks, including inventory management, order picking, and delivery.

Businesses may increase the accuracy and speed of their operations while cutting the time and expense of manual labour and transportation by utilising drone technology. Drones can also increase the flexibility and scalability of intralogistics, allowing businesses to quickly adjust to fluctuations in demand.

Moreover, drones can improve efficiency and reduce the risk of accidents or injuries for workers who might otherwise need to use ladders or other equipment to access these areas. In addition, drones can gather information on inventory levels, product quality, and other key metrics, providing businesses with valuable insights into their operations by using sensors and cameras. This data can be used to optimize processes, improve forecasting, and reduce waste, leading to cost savings and improved efficiency. All these above-mentioned factors are expected to create growth opportunities for the intralogistics market in the near future.

Competitive Landscape

The Italy intralogistics industry includes several market players such as Daifuku Co. Ltd., Jungheinrich AG, Kion Group AG, Honeywell International Inc., Midea Group, Vanderlande Industries B.V., SSI Schaefer AG, KNAPP AG, Beumer Group Gmbh and Co. KG, and Autostore.

Key Benefits

-

The Italy intralogistics market report provides a quantitative analysis of the current market and estimations through 2023-2030 that assists in identifying the prevailing market opportunities to capitalize on.

-

The study comprises a deep dive analysis of the market trend including the current and future trends for depicting the prevalent investment pockets in the market.

-

The information related to key drivers, restraints, and opportunities and their impact on the market is provided in the report.

-

The competitive analysis of the market players along with their market share in the Italy intralogistics market.

-

The SWOT analysis and Porter’s Five Forces model are elaborated in the study.

-

Value chain analysis in the market study provides a clear picture of the stakeholders’ roles.

Italy Intralogistics Market Key Segments

By Component

-

Hardware

-

Automated Storage and Retrieval Systems (AS/RS)

-

Unit-Load AS/RS

-

Mini-Load AS/RS

-

Vertical Lift Modules (VLMs)

-

Carousel AS/RS

-

-

Industrial Robots

-

Mobile Robots

-

Automated Guided Vehicles (AGV)

-

Autonomous Mobile Robots (AMR)

-

-

Conveyor Systems

-

Sortation Systems

-

-

Software

-

Services

By End User Industry

-

Logistics

-

Food And Beverages

-

Retail And E-Commerce

-

Automotive

-

Chemicals

-

Pharmaceuticals

-

Airport

-

Mining

REPORT SCOPE AND SEGMENTATION:

|

Parameters |

Details |

|

Market Size in 2022 |

USD 1.58 Billion |

|

Revenue Forecast in 2030 |

USD 5.66 Billion |

|

Growth Rate |

CAGR of 17.1% from 2023 to 2030 |

|

Analysis Period |

2022–2030 |

|

Base Year Considered |

2022 |

|

Forecast Period |

2023–2030 |

|

Market Size Estimation |

Billion (USD) |

|

Growth Factors |

Increasing adoption of industry 4.0 Supreme supply chain optimization. |

|

Companies Profiled |

10 |

|

Market Share |

Available for 10 companies |

|

Customization Scope |

Free customization (equivalent up to 80 working hours of analysts) after purchase. Addition or alteration to country, regional, and segment scope. |

|

Pricing and Purchase Options |

Avail customized purchase options to meet your exact research needs. |

KEY PLAYERS

-

Daifuku Co. Ltd.

-

Jungheinrich AG

-

Kion Group AG

-

Honeywell International Inc.

-

Midea Group

-

Vanderlande Industries B.V.

-

SSI Schaefer AG

-

KNAPP AG

-

Beumer Group Gmbh and Co. KG

-

Autostore

Speak to Our Analyst

Speak to Our Analyst