How AI-Powered AS/RS Revolutionizing Warehouse Automation

28-Apr-2025

Introduction

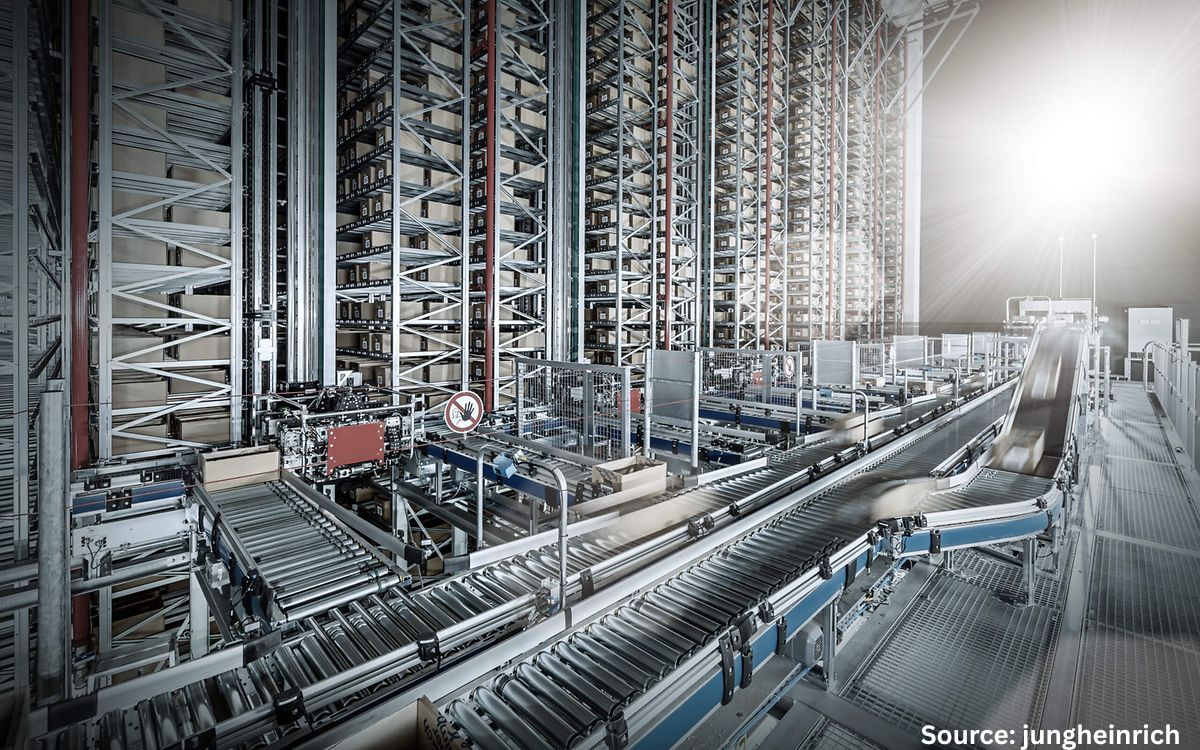

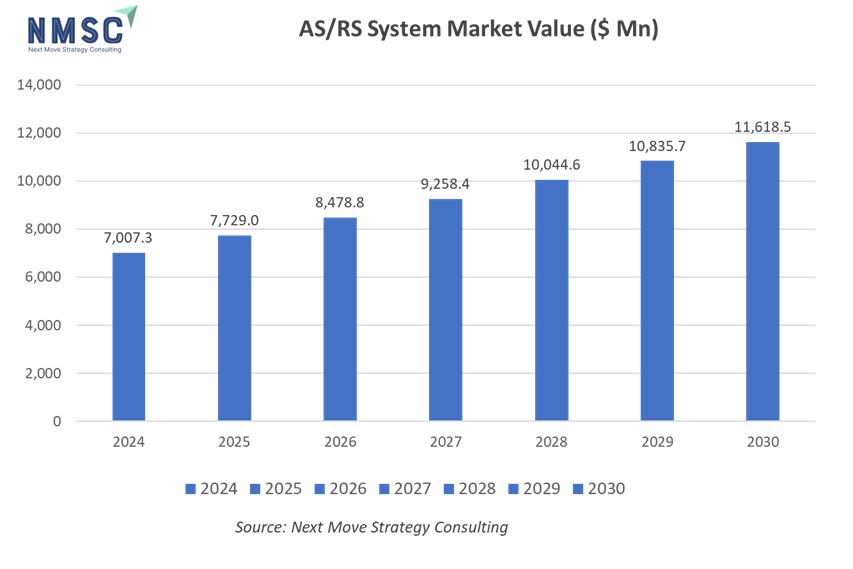

In the contemporary fast paced global economy, the demand for efficient, accurate and scalable warehouse operation is at high rise. Traditional manual methods struggle to keep a pace with complexities of the modern supply chain resulting in increased interest in automation solutions. Among this artificial intelligence powered automated storage and retrieval system is transforming how warehouse function.

Understanding Artificial Intelligence Powered AS/RS

Automated storage and retrieval system are designed to automatically place and retrieve loads from the storage locations. The integration of artificial intelligence in these systems helps to enhance their capabilities enabling real time decision making, predictive analytics and adaptive learnings.

This integration results in:

Increased Efficiency: Artificial intelligence algorithm helps to optimize storage layouts and retrieval paths that reduces the time taken to process the orders.

Enhanced Accuracy: Machine Learning model help to predict demand patterns, minimising stock discrepancies and overstock situations.

Scalability: Artificial intelligence driven system adapts to varying workloads, ensuring consistent performance during peak times.

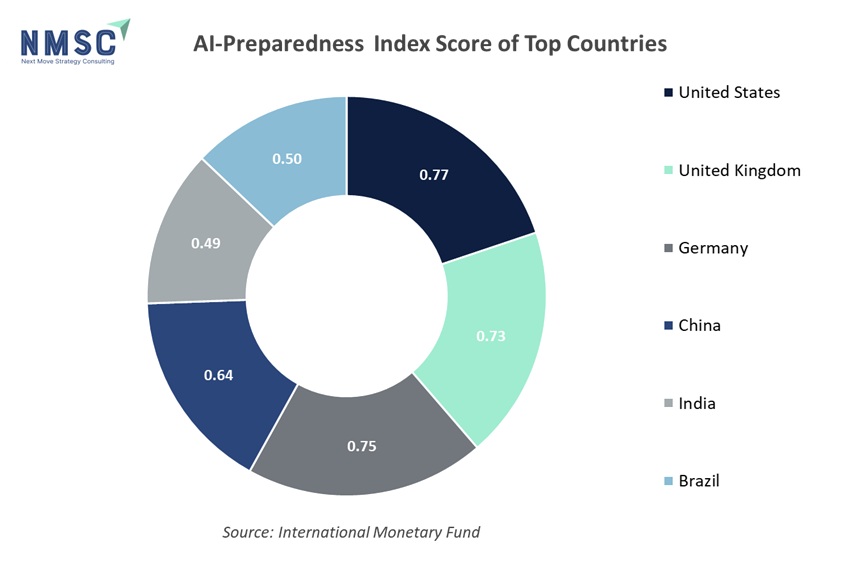

Adoption of Robotics and AS/RS Across Different Regions

North America

In the North America region particularly in the U.S. there is a significant shift towards automation. Companies such as Amazon are at the forefront of integrating over 750,000 robots integrated in the fulfilment centres to streamline operations and reduce costs. Similarly, Symbiotics offers artificial intelligence robotic solution to leading retailers in the region such as Walmart and Target enhancing the inventory management and order fulfilment.

Europe

European countries are also adopting artificial intelligence AS/RS to improve efficiency and address labour shortage. Companies such as Korber Supply Chain Automation partnered with robotics firms for implementation of warehouse solutions that caters to the growing e-commerce sector needs.

Asia-Pacific

The Asia-Pacific region with its growing e-commerce sector is adopting warehouse automation solutions. Such automation technology delivers higher picking accuracy, reduce processing time and fully utilize the storage capacity of a warehouse that helps businesses keep pace with customers' expectations to receive speedy delivery.

According to the recent report of the Ministry of Commerce and Industry, the Indian e-commerce market will be worth USD 325 billion by 2030. Such rise in e-commerce sector mandates the use of artificial intelligence based automated storage and retrieval system.

In South Korea for instance, companies such as SYNUS tech are advancing smart factory robotics solutions that indicates a strong regional commitment towards integration of artificial intelligence in logistics sector.

Latest Innovations in Artificial Intelligence Powered AS/RS

The sector of automated storage and retrieval system is constantly evolving with companies launching innovative solutions to meet the dynamic needs of the logistics sector.

3D Robotics Storage of Attabotics

Attabotics, for instance developed a storage system that helps to minimize warehouse foot prints to around 85%. The intelligent robots navigate vertically and horizontally within a modular structure that optimize space and retrieval times. Notably, the company entered into partnership with major retailers to streamline supply chains that reflects the adaptability and efficiency of the system.

Artificial Intelligence Driven Orchestration System in Warehouse Automation of Vecna Robotics

Vecna Robotics specializes in automated material handling solutions that includes autonomous pallet trucks and tuggers. The artificial intelligence driven orchestration engine solution integrates with the existing warehouse management system that optimizes workflow and enhances the productivity. Deployments in distribution centres demonstrated advanced improvements in the fulfilment speeds and accuracy. The integration of artificial intelligence in the automated retrieval and storage solutions helps to optimize workflows, improve efficiency and fasten operational flow.

Amazon Robotics Initiative

Amazon continues its innovation in the warehouse robotics market through introduction of robotics such as Proteus that includes a complete autonomous mobile robot along with Sparrow that includes a robotic arm controller that is capable of handling individual items. These advancements fasten delivery times along with improving warehouse efficiency, reducing errors and lowering the labour costs.

Micro-Fulfilment Centers of Ocado

With the rise in demand for same day delivery by customers, companies are adopting solutions to fasten last minute delivery. Micro fulfilment centers are small artificial intelligence driven warehouses designed for quick order processing in the urban areas.

For instance, Ocado developed an artificial intelligence automated storage and retrieval system that utilize swarms of robots to pick and pack grocery orders with the unmatched efficiency. The robots are able to assemble orders within five minutes, reducing delivery times compared to traditional fulfilment models.

Conclusion

The latest innovations in artificial intelligence powered automated storage and retrieval system are introducing a new era of warehouse automation. Various companies ae finding ways to enhance efficiency, reduce costs and enhance supply chain management. The integration of artificial intelligence in the automated storage and retrieval system makes it smarter, adaptive and more responsive to the real time needs of the companies. Businesses that are adopting this transformative technology would gain competitive advantage in the supply chain management.

About the Author

Sukanya Dey is a passionate and insightful writer with over three years of experience, she excels in providing clients with in-depth research and valuable insights, helping them navigate complex business challenges. She has a keen interest in various industries, including Retail and Consumer, Healthcare, Manufacturing, Automotive, and ICT & Media. Sukanya strives to offer fresh perspectives and innovative solutions through her comprehensive research. She finds immense joy in weaving her thoughts and ideas into captivating articles and blogs, where her passion for literature and art shines through. In her free time, she enjoys reading books, cooking, filming, often drawing inspiration from these activities for her creative writing endeavors. The author can be reached at [email protected]

Sukanya Dey is a passionate and insightful writer with over three years of experience, she excels in providing clients with in-depth research and valuable insights, helping them navigate complex business challenges. She has a keen interest in various industries, including Retail and Consumer, Healthcare, Manufacturing, Automotive, and ICT & Media. Sukanya strives to offer fresh perspectives and innovative solutions through her comprehensive research. She finds immense joy in weaving her thoughts and ideas into captivating articles and blogs, where her passion for literature and art shines through. In her free time, she enjoys reading books, cooking, filming, often drawing inspiration from these activities for her creative writing endeavors. The author can be reached at [email protected]

Add Comment

Related Blogs

Top 10 Companies Operating in the Global Elevator Industry

Next Move Strategy Consulting Forecasts strong growth in the global Elevator Mar...

Powerhouses of Intralogistics: How Honeywell and KION Are Revolutionizing the Future of Automation

The intralogistics industry is anticipated to witness a grow...

TAM, SAM, VAM Insights into Germany Intralogistics Market

Introduction The Germany intralogistics market is poised for substantial grow...