Impact of Green Policies and Carbon Regulations on Aluminum Market

12-Mar-2025

The aluminium market is undergoing significant transformation that is driven by the global green policies and stringent regulations. These environmental policies are reshaping production processes, strategic directions of leading companies and market dynamics.

This blog explores about the multifaceted impact of the green policies on the aluminium market along with highlighting recent technological advancements and corporate initiative aimed towards sustainability that is shaping the aluminium sector.

Environmental Footprint of Aluminum Production

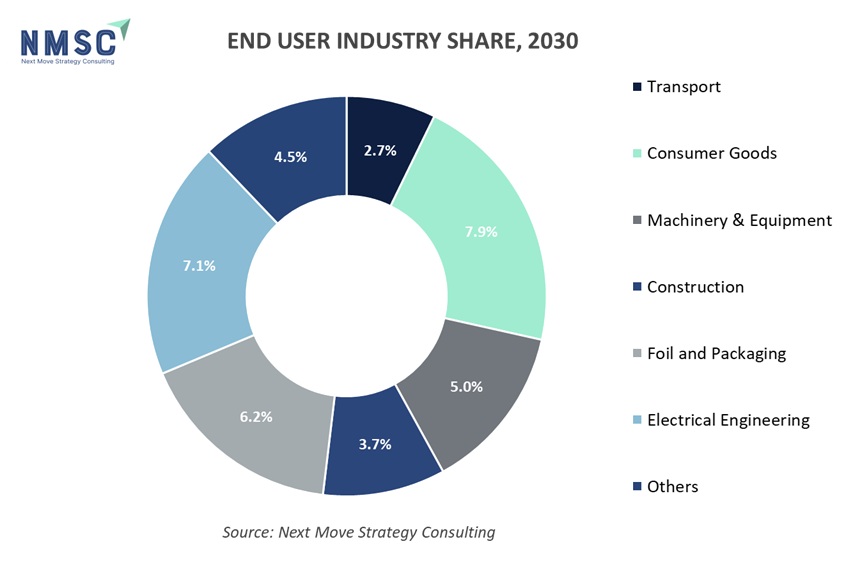

The versality and lightweight properties of aluminium make it unavoidable in numerous industries ranging from transport to electrical engineering as depicted in the pie chart below. However, its production is energy intensive fossil fuel based that leads to high greenhouse gas emissions. As global focus increases to mitigate climate change, the need to decarbonize also increase.

Green policies and regulations comply producers to innovate and influence market trends and competitiveness. Based on the report of the International Aluminium Institute, the global level of emission from aluminium production, both primary metal and recycling reached 10.04 tons in 2023.

Green Policies and Carbon Regulations: A Catalyst for Change

Due to the climate change, governments around the world are implementing policies that aims towards reducing industrial emission. For the aluminium sector, this implies stricter emission regulations and incentives for cleaner technology.

For instance, in the European Union, the Carbon Border Adjustment Mechanism imposes a tariff on carbon-intensive imports, like aluminum, to encourage cleaner production. The EU Emissions Trading System also sets a cap on emissions, driving aluminum producers to employ greener technology like hydro-powered smelting, such as Norway's aluminum industry.

Similarly, in China, the government introduced dual control policies to limit energy consumption and intensity of high-energy industries like aluminum production. The country is also expanding its green electricity trading system, which allows aluminum producers to buy renewable energy, thereby reducing the consumption of coal-powered smelting.

Chinese majors such as China Hongqiao Group are investing in hydropower-based aluminum production in Yunnan province to comply with these policies. These regulations drive the transition towards environmentally friendly practices that forces companies towards re-thinking their manufacturing processes and source of energy.

Start with a FREE Sample – Download Now!

Technological Innovations Driving Decarbonization

To satisfy the demands of the environment, the aluminium industry is investing in groundbreaking technology that is being brought to light in the discussion below:

Inert Anode Technology: Inert materials are replacing carbon anodes, preventing CO₂ emissions in the process of electrolysis and producing oxygen. Groundbreaking companies like ELYSIS, a partnership between Alcoa and Rio Tinto, are leading this technology with assistance from big investors like Apple.

HalZero Process: Hydro created the HalZero technology, wherein carbon and chlorine remain in a circuit that is closed during the process of electrolysis, hence reducing carbon dioxide emissions and releasing oxygen alone. Large-scale manufacture will be achieved in 2030, with initial production of aluminium by 2025.

Corporate Initiatives Towards Sustainability

3x30 Initiative of Novelis: Novelis launched the 3x30 initiative with the aim of increasing recycled content, reducing carbon emissions and promoting circularity in the production of aluminum. The initiative reflects the commitment of the company to environmental stewardship and leadership in sustainability.

Ball Corporation's Leadership on Climate: Ball Corporation is restructuring its value chain to keep aluminum within a closed-loop recycling loop. By employing renewable power, achieving 30% energy efficiency gains, and converting to alternative heat sources, Ball aims to cut 55% of Scope 1 and 2 emissions by 2030.

Shutdowns of Aluminium Plants Due to Emission Issues

The pressure to reduce the emission of greenhouse gases led to the shutting down of a number of aluminum smelters, particularly where fossil fuel consumption dominates. In Europe, for instance, aluminum firm Speira announced that it would shut down its Rheinwerk plant in Germany because of the tight energy market and emission reduction requirements. The closure is indicative of the struggle of aluminum manufacturers to balance production requirements and environmental promises.

Such shutdowns and interventions by regulators underline the need for the aluminum industry to innovate and transform into more sustainable modes of production. Not doing so threatens not just the feasibility of individual operations but also poses difficulties in meeting global climate.

International Collaboration and Future Focus

Reducing emissions dramatically in the aluminum sector requires working together within the value chain, e.g., suppliers, manufacturers, and customers. Actions such as the Aluminium Stewardship Initiative are invaluable in setting a benchmark and leading the way in climate compatible avenues.

In the coming years, the emphasis of aluminum sector on sustainability and innovation will redefine its place in the global economy. With companies increasingly adopting green technologies and carbon compliance, aluminum will be a standard for balancing industrial growth with environmental protection.

Conclusion

The intersection of green policies and carbon regulations is driving the transformative shift towards aluminium market. Through technological advancements, strategic corporate initiatives and enhanced recycling efforts, the industry is adopting vital actions towards reducing its carbon footprint. Moreover, the collective momentum towards sustainability offers a promising pathway towards aluminium sector to move towards an eco-conscious future.

About the Author

Sukanya Dey is a passionate and insightful writer with over three years of experience, she excels in providing clients with in-depth research and valuable insights, helping them navigate complex business challenges. She has a keen interest in various industries, including Retail and Consumer, Healthcare, Manufacturing, Automotive, and ICT & Media. Sukanya strives to offer fresh perspectives and innovative solutions through her comprehensive research. She finds immense joy in weaving her thoughts and ideas into captivating articles and blogs, where her passion for literature and art shines through. In her free time, she enjoys reading books, cooking, filming, often drawing inspiration from these activities for her creative writing endeavors. The author can be reached at [email protected]

Sukanya Dey is a passionate and insightful writer with over three years of experience, she excels in providing clients with in-depth research and valuable insights, helping them navigate complex business challenges. She has a keen interest in various industries, including Retail and Consumer, Healthcare, Manufacturing, Automotive, and ICT & Media. Sukanya strives to offer fresh perspectives and innovative solutions through her comprehensive research. She finds immense joy in weaving her thoughts and ideas into captivating articles and blogs, where her passion for literature and art shines through. In her free time, she enjoys reading books, cooking, filming, often drawing inspiration from these activities for her creative writing endeavors. The author can be reached at [email protected]

Add Comment

Related Blogs

Top Companies Shaping The Future Of Aluminium Production And Supply

The aluminium sector is expected to see a mind-boggling grow...

Cold Pipe Insulation Market: Why Giants Hold 70% Share

Next Move Strategy Consulting forecasts a notable upsurge in the Cold Pipe Insul...

Why Norsk Hydro Leads the Aluminium Market with 28% Share

The aluminium market is expected to see a remarkable growth of around 1.5X,...