Asia-Pacific Aluminium Market by Product Type (Flat-Rolled, Castings, Extrusions, Forgings, Powder & Paste, and Other Types), by Type (Primary and Secondary), and by End-User Industry (Transport, Consumer Goods, Machinery & Equipment, Construction, Foil & Packaging, Electrical Engineering, and Others) – Opportunity Analysis and Industry Forecast, 2024–2030

Industry: Materials and Chemical | Publish Date: 17-Feb-2025 | No of Pages: 237 | No. of Tables: 169 | No. of Figures: 94 | Format: PDF | Report Code : MC1338

US Tariff Impact on Asia-Pacific Aluminium Market

Trump Tariffs Are Reshaping Global Business

Asia-Pacific Aluminium Market Overview

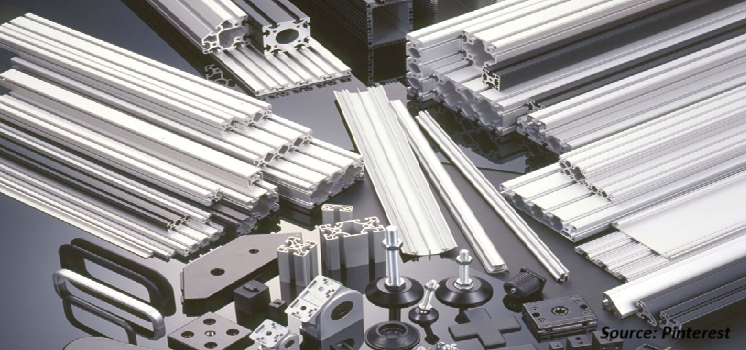

Asia-Pacific Aluminium Market size was valued at USD 102.86 billion in 2023, and is predicted to reach USD 149.96 billion by 2030, at a CAGR of 5.6% from 2024 to 2030. The aluminium market involves the industry dedicated to producing, distributing, and using aluminium, a lightweight and silvery-white metal. Aluminium constitutes about 8% of the Earth's crust and is known for its low density, high strength, and natural corrosion resistance due to an oxide layer. These characteristics make aluminium valuable in sectors such as aerospace, automotive, construction, packaging, and electronics. Its lightweight property enhances efficiency, particularly in transportation. Aluminium is manufactured from bauxite ore through the Bayer process and electrolysis. Advances in technology and recycling have improved the energy efficiency and sustainability of production, supporting the industry's growth.

The Expanding Automotive Industry Drives Market Growth in Asia-Pacific

The expanding automotive sector is driving the demand for aluminum in the Asia-Pacific region. As automotive industries in countries such as China, South Korea, and India grow, the need for aluminum increases due to its lightweight and durable properties, that enhance vehicle efficiency and performance. Aluminum is essential for manufacturing various automotive components, including body panels, engine parts, and structural elements. The rise in vehicle production and sales in the region is significantly boosting the demand for aluminum, supporting the overall growth of the aluminum market in Asia-Pacific.

Infrastructure Development and Industrialization Drives Aluminum Demand in Asia-Pacific

Infrastructure development and rapid industrialization are key factors propelling aluminum demand across the Asia-Pacific region. In India, large-scale infrastructure projects and airport modernization efforts are significantly boosting the need for aluminum in construction and aviation. Thailand's growing construction industry and infrastructure development also contribute to the rising demand for aluminum.

Similarly, Indonesia's expanding construction and infrastructure sectors are major drivers of aluminum consumption. Australia's strong mining and smelting industries ensure a steady supply of raw materials to support domestic aluminum production. In Singapore, urbanization and advancements in precision engineering further stimulate market growth. Additionally, countries like Vietnam, the Philippines, and Malaysia are experiencing increased aluminum demand in sectors such as manufacturing, packaging, construction, and renewable energy, which supports the overall growth of the aluminum market in the Asia-Pacific region.

Environmental and Regulatory Constraints Hinders the Growth of Aluminium Market

The aluminium industry faces challenges from environmental regulations and sustainability requirements, including emissions control, waste management, and energy efficiency targets, that leads to higher operational costs for some producers. Compliance with strict emissions standards, waste management rules, and energy consumption goals often necessitates substantial investments and efforts to reduce the environmental impact of aluminium production. These sustainability measures are designed to minimize emissions, ensure responsible waste management, and promote energy efficiency. Although these regulations are essential for fostering a greener and more sustainable industry, they also contribute to the overall costs and complexities of aluminium production.

Sustainable Packaging Creates Ample Future Opportunities

The growing focus on sustainable packaging is expected to provide significant growth opportunities for the aluminium market in the future. Aluminium is ideal for packaging applications such as cans, bottles, and foils due to its recyclability and ability to preserve product quality and freshness. Eco-conscious consumers and brands looking to reduce their environmental impact increasingly choose aluminium as a preferred packaging material. By selecting aluminium, they help reduce waste and support sustainability, aligning with their commitment to a greener future. This rising demand for sustainable packaging solutions is a key driver of the Asia-Pacific aluminium market growth.

China Holds the Dominant Market Share in Asia-Pacific Aluminium Market

The expansion of China's automotive sector is significantly driving the growth of the aluminum market. Aluminum is increasingly favored in the automotive industry due to its lightweight properties, which enhance vehicle efficiency by reducing overall weight and improving fuel economy. The demand for aluminum is rising as it becomes essential in manufacturing critical vehicle components, such as car bodies, engine parts, and structural elements. With China's automotive production expected to reach 35 million vehicles by 2025, according to the International Trade Administration, the need for aluminum is set to grow correspondingly. This increase in vehicle production underscores the importance of aluminum in advancing vehicle technology and performance, further fueling the growth of the aluminum market in China.

The expansion of China's aviation sector is a key driver of aluminum demand. Aluminum's lightweight and durable properties make it essential for manufacturing various aircraft components, including frames, wings, fuselages, and interior parts. As China's aviation industry grows, the demand for aluminum rises, creating more opportunities for suppliers and manufacturers. This increased demand aligns with China's efforts to advance its aviation capabilities, with modern aircraft designs and technologies requiring high-performance materials. Consequently, the growth in aircraft production and maintenance is driving higher aluminum consumption, further boosting the market and offering substantial growth prospects for the aluminum industry.

Thailand to Witness Substantial Growth in the Asia-Pacific Aluminium Market

Urbanization and infrastructure development are significant drivers of the aluminum market in Thailand. With the country undergoing rapid urban expansion, the demand for new buildings, transportation systems, and other infrastructure projects is increasing.Aluminum's strength, lightweight properties, and resistance to corrosion make it a preferred material for these developments. Its versatility allows for the construction of durable structures and efficient transportation networks that align with modern standards. The surge in construction activity is elevating the demand for aluminum, positioning it as a crucial element in Thailand's ongoing infrastructure projects and urban growth.

The Asia-Pacific aluminium market expansion of the automotive industry in Thailand is another significant factor driving the increasing demand for aluminium. As the automotive sector grows, there is a rising need for lightweight materials to enhance vehicle performance and fuel efficiency. Aluminium, known for its low density and high strength, is increasingly used in vehicle manufacturing, including in car bodies, engine components, and structural parts. The Thai automotive industry’s focus on producing more energy-efficient and high-performance vehicles is fueling the Asia-Pacific aluminium market demand. Additionally, as the industry expands its production capabilities and integrates advanced technologies, the need for aluminium continues to rise. This growth in the automotive sector not only boosts the demand for aluminium but also supports the development of related industries and contributes to the overall market expansion in Thailand.

Competitive Landscape

Several key players operating in the Asia-Pacific aluminium industry include China Hongqiao Group Limited, Aluminum Corporation of China Limited, East Hope Group Company Limited, Xinfa Group Co., Ltd., Hindalco Industries Ltd., Rio Tinto, Vedanta Aluminium & Power, Jindal Aluminium Limited, United Company RUSAL PLC., BALCO (BHARAT ALUMINIUM COMPANY LIMITED, GAL ALUMINIUM EXTRUSIONS PVT. LTD, JUPALCO, MANAKSIA ALUMINIUM COMPANY LIMITED, CENTURY EXTRUSIONS LIMITED, Arconic Inc., Alcoa Corporation, Norsk Hydro ASA, NATIONAL ALUMINIUM COMPANY LIMITED (NALCO), Nippon Light Metal Company Ltd., UACJ Corporation, and others.

Asia-Pacific Aluminium Market Key Segments

By Product Type

-

Flat-Rolled

-

Castings

-

Extrusions

-

Forgings

-

Powder & Paste

-

Other Types

By Type

- Primary

-

Secondary

By End-User Industry

-

Transport

-

Consumer Goods

-

Machinery & Equipment

-

Construction

-

Foil & Packaging

-

Electrical Engineering

-

Others

By Country

- China

-

Japan

-

India

-

South Korea

-

Australia

-

Indonesia

-

Singapore

-

Taiwan

-

Thailand

-

Rest of Asia-Pacific

Key Players

-

China Hongqiao Group Limited

-

Aluminum Corporation of China Limited

-

East Hope Group Company Limited

-

Xinfa Group Co., Ltd.

-

Hindalco Industries Ltd.

-

Rio Tinto

-

Vedanta Aluminium & Power

-

Jindal Aluminium Limited

-

United Company RUSAL PLC.

-

BALCO (BHARAT ALUMINIUM COMPANY LIMITED

-

GAL ALUMINIUM EXTRUSIONS PVT. LTD

-

JUPALCO

-

MANAKSIA ALUMINIUM COMPANY LIMITED

-

CENTURY EXTRUSIONS LIMITED

-

Arconic Inc.

-

Alcoa Corporation

-

Norsk Hydro ASA

-

NATIONAL ALUMINIUM COMPANY LIMITED (NALCO)

-

Nippon Light Metal Company Ltd.

-

UACJ Corporation

REPORT SCOPE AND SEGMENTATION:

|

Parameters |

Details |

|

Market Size in 2023 |

USD 102.86 Billion |

|

Revenue Forecast in 2030 |

USD 149.96 Billion |

|

Growth Rate |

CAGR of 5.6% from 2024 to 2030 |

|

Base Year Considered |

2023 |

|

Forecast Period |

2024–2030 |

|

Market Size Estimation |

Billion (USD) |

|

Growth Factors |

|

|

Countries Covered |

10 |

|

Companies Profiled |

10 |

|

Market Share |

Available for 10 companies |

|

Customization Scope |

Free customization (equivalent up to 80 working hours of analysts) after purchase. Addition or alteration to country, regional, and segment scope. |

|

Pricing and Purchase Options |

Avail customized purchase options to meet your exact research needs. |

Speak to Our Analyst

Speak to Our Analyst